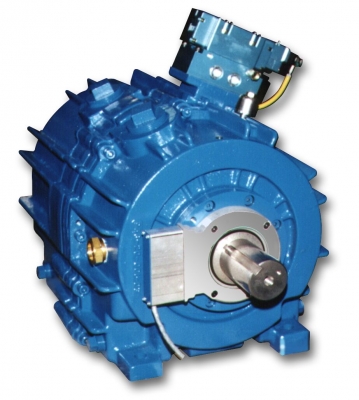

Posidyne clutch brakes feature oil shear technology for rapid and precise stopping, starting, speed change and positioning, all without adjustment or maintenance. Ideal for applications with frequent start/stop cycles, such as indexing conveyors, rotary tables, batch feeders, rotary coal samplers, cutoff machines, and more, these unique motion control devices allow higher cycle rates (up to 300 cycles per minute), to increase production rates with lower downtime. Faster production rates and significantly longer service life than traditional (dry) clutch/brakes (often 5 to 10 times longer) yields increased uptime, productivity and ROI. Posidyne clutch/brakes are field proven in diverse applications such as lumber mills, shingle plants, fiberglass insulation production, food processing, packaging, metalworking, and many more.

Next B&R Automation Software Simplifies Management of Machine Variants

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.