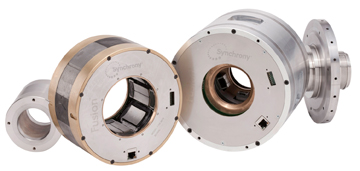

The integration of mechanical and electrical devices on magnetic bearings have altered their potential application by reducing their size and enabling industrial equipment designs that feature reduced maintenance requirements.

Recent advances in magnetic bearing technology, including controls miniaturization, higher levels of simplicity and integrated product solutions, plus the overall machinery trend to more directly drive machines without gearboxes, are overcoming past limitations inherent to magnetic bearings. As a result, magnetic bearings are replacing oil-lubricated bearings for many new types of machines in a variety of industries.

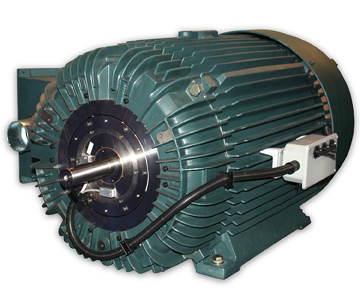

A key factor driving magnetic bearing applications is interest in directly driven machines where there is a high-speed motor coupled to the fluid machine. Instead of needing gearboxes and oil lubrication systems, you can use a more efficient system that incorporates a high speed, permanent magnet motor and magnetic bearings.

Users are adopting the bearings into refrigeration compressors for chillers and HVAC. In addition, magnetic bearings are increasingly used in general industry pump applications to help reduce maintenance costs.

Recent advancements have digitized the whole drive train, and the digital controllers have become much smaller. The control cabinet has been dramatically reduced in size, and magnetic bearings are being applied in applications other than for very large machines, expensive compressors or turbines.

Magnetic bearings help remove components, and the train now looks like a direct machine with a high-speed, permanent magnet motor that uses magnetic bearings. The application doesn't need the gearbox, the oil lubrication system and the compressor wheel mount directly on the shaft of the motor.

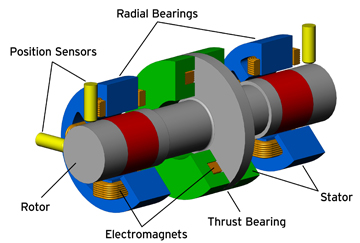

The magnetic bearing controller uses electromagnetic coils around the stator (which is the fixed component of the magnetic bearing). For a radial bearing configuration, laminations on the shaft itself are attracted by the magnetic field induced by the electromagnetic coils. Position sensors also monitor the shaft, and clearances are measured in thousandths of an inch.

Energizing the magnetic bearing levitates the shaft, and it starts to spin driven by the motor and VFD (if one is used in the application). The shaft is levitated and running up to speed, but the load is varying.

Another reason behind increased interest in magnetic bearings is the availability of information from them. This means that users can now monitor what forces are acting on the shaft. Over time, an application may experience higher degrees of vibration, high side loads and be able to determine what forces are acting on the shaft, temperatures and the position of the shaft.

The integration of mechanical and electrical devices on magnetic bearings have altered their potential application by reducing their size and enabling industrial equipment designs that feature reduced maintenance requirements.

Recent advances in magnetic bearing technology, including controls miniaturization, higher levels of simplicity and integrated product solutions, plus the overall machinery trend to more directly drive machines without gearboxes, are overcoming past limitations inherent to magnetic bearings. As a result, magnetic bearings are replacing oil-lubricated bearings for many new types of machines in a variety of industries.

A key factor driving magnetic bearing applications is interest in directly driven machines where there is a high-speed motor coupled to the fluid machine. Instead of needing gearboxes and oil lubrication systems, you can use a more efficient system that incorporates a high speed, permanent magnet motor and magnetic bearings.

Users are adopting the bearings into refrigeration compressors for chillers and HVAC. In addition, magnetic bearings are increasingly used in general industry pump applications to help reduce maintenance costs.

Recent advancements have digitized the whole drive train, and the digital controllers have become much smaller. The control cabinet has been dramatically reduced in size, and magnetic bearings are being applied in applications other than for very large machines, expensive compressors or turbines.

Magnetic bearings help remove components, and the train now looks like a direct machine with a high-speed, permanent magnet motor that uses magnetic bearings. The application doesn't need the gearbox, the oil lubrication system and the compressor wheel mount directly on the shaft of the motor.

The magnetic bearing controller uses electromagnetic coils around the stator (which is the fixed component of the magnetic bearing). For a radial bearing configuration, laminations on the shaft itself are attracted by the magnetic field induced by the electromagnetic coils. Position sensors also monitor the shaft, and clearances are measured in thousandths of an inch.

Energizing the magnetic bearing levitates the shaft, and it starts to spin driven by the motor and VFD (if one is used in the application). The shaft is levitated and running up to speed, but the load is varying.

Another reason behind increased interest in magnetic bearings is the availability of information from them. This means that users can now monitor what forces are acting on the shaft. Over time, an application may experience higher degrees of vibration, high side loads and be able to determine what forces are acting on the shaft, temperatures and the position of the shaft.

Next Thordon Composite Dredge Cutter Lineshaft Bearings

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.