NSK has developed a package that is designed to enable ball bearings to be used successfully in applications where high temperatures up to 200C are expected.

The highly integrated nature of modern engineering structures offers advantages in terms of size, weight and cost reductions.

However, in many applications the trade-off for these advantages is increased heat - higher-temperature operation as a result of excess heat, either generated internally from items such as motors, or externally from adjacent components in the same equipment or assembly.

This problem is no more obvious than in modern automotive manufacture, with components stacked tightly together to reduce the overall size envelope.

The same difficulty is also encountered in pumps, compressors and motor sets, as well as the more conventional applications in ovens and furnaces.

However, while the problem of high-temperature operation is well understood and catered for in the latter applications, the same cannot be said, generally, for the newer generation of integrated engineering applications.

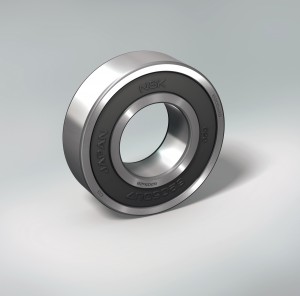

The problem of using standard bearings, 6205 ball bearings, for example, at elevated temperatures is an example of this.

When standard ball bearings are operated in temperatures above 100C, dimensional changes occur that can lead to inner ring creep, a condition where the bearing ring rotates slowly in relation to its seating.

This can result in scoring, noise, vibration, wear - and eventual premature failure of the bearing.

In addition, seals and lubrication can also degrade rapidly over 100C.

The standard Nitrile rubber seals used in deep-groove bearings have a maximum operating temperature of about 110C, and standard lubricant greases are often limited to the same figure.

A further consideration when standard bearings are used at high temperature is internal clearance, which can influence noise, vibration, heat build-up and fatigue life.

Bearings are designed with a specific internal clearance that measures the total clearance between the rings and the rolling elements.

This provides compensation for fitting and thermal expansion.

However, when high-temperature differentials are present, the standard clearance can be greatly reduced, leading to radial loading on the bearing and subsequent fatigue spalling in the bearing inner raceway, which usually result in bearing failure.

NSK has developed a comprehensive package of measures that effectively addresses the issues of using standard bearings at high temperatures, providing improved material specification, sealing, lubrication and internal clearance.

All deep-groove ball bearings produced by NSK are manufactured using the company's long-life Z-Steel material.

This is produced by reducing the amount of non-metallic inclusions, oxide and other inclusions in the steel.

The benefit is that bearings made from the steel have an extended service life when compared with conventional vacuum-degassed steel: up to 1.8 times longer.

To reduce the potential for inner ring creep, NSK offers two grades of heat-treated steel, which improve the dimensional stability of the bearing when operating at elevated temperatures: X26, for operation up to 150C, and X28 for applications up to 200C.

Complementing the high-temperature performance of the dimensionally established steels, NSK has developed fluorine and silicone rubber seals - or metal shields - all of which offer good performance up to 200C.

These are used in conjunction with specially developed high-temperature greases, such as NSK's ENS-type, which functions reliably up to 160C, with other greases for operation up to 250C on request.

These greases are said to offer superior thermal stability and high-temperature durability, combined with long life and high temperatures.

Generally, internal clearances are designated from C1 (the smallest) through to C5 (the largest).

The 'normal' clearance is CN, a range sitting between C2 and C3.

NSK offers its high-temperature deep-groove ball bearings with C3 or C4 clearance, giving improved performance and longer lifetimes in applications with high temperatures or where large temperature differentials through the bearing are present.

Where the requirement is for bearing operation in excess of 200C, NSK offers the Spacea range of products.

These bearings redefine the operating parameters for high-temperature bearings in all areas of manufacturing and processing technology, with new materials and designs that provide high levels of performance in normal atmospheric and vacuum environments at temperatures up to 400C.

NSK has developed a package that is designed to enable ball bearings to be used successfully in applications where high temperatures up to 200C are expected.

The highly integrated nature of modern engineering structures offers advantages in terms of size, weight and cost reductions.

However, in many applications the trade-off for these advantages is increased heat - higher-temperature operation as a result of excess heat, either generated internally from items such as motors, or externally from adjacent components in the same equipment or assembly.

This problem is no more obvious than in modern automotive manufacture, with components stacked tightly together to reduce the overall size envelope.

The same difficulty is also encountered in pumps, compressors and motor sets, as well as the more conventional applications in ovens and furnaces.

However, while the problem of high-temperature operation is well understood and catered for in the latter applications, the same cannot be said, generally, for the newer generation of integrated engineering applications.

The problem of using standard bearings, 6205 ball bearings, for example, at elevated temperatures is an example of this.

When standard ball bearings are operated in temperatures above 100C, dimensional changes occur that can lead to inner ring creep, a condition where the bearing ring rotates slowly in relation to its seating.

This can result in scoring, noise, vibration, wear - and eventual premature failure of the bearing.

In addition, seals and lubrication can also degrade rapidly over 100C.

The standard Nitrile rubber seals used in deep-groove bearings have a maximum operating temperature of about 110C, and standard lubricant greases are often limited to the same figure.

A further consideration when standard bearings are used at high temperature is internal clearance, which can influence noise, vibration, heat build-up and fatigue life.

Bearings are designed with a specific internal clearance that measures the total clearance between the rings and the rolling elements.

This provides compensation for fitting and thermal expansion.

However, when high-temperature differentials are present, the standard clearance can be greatly reduced, leading to radial loading on the bearing and subsequent fatigue spalling in the bearing inner raceway, which usually result in bearing failure.

NSK has developed a comprehensive package of measures that effectively addresses the issues of using standard bearings at high temperatures, providing improved material specification, sealing, lubrication and internal clearance.

All deep-groove ball bearings produced by NSK are manufactured using the company's long-life Z-Steel material.

This is produced by reducing the amount of non-metallic inclusions, oxide and other inclusions in the steel.

The benefit is that bearings made from the steel have an extended service life when compared with conventional vacuum-degassed steel: up to 1.8 times longer.

To reduce the potential for inner ring creep, NSK offers two grades of heat-treated steel, which improve the dimensional stability of the bearing when operating at elevated temperatures: X26, for operation up to 150C, and X28 for applications up to 200C.

Complementing the high-temperature performance of the dimensionally established steels, NSK has developed fluorine and silicone rubber seals - or metal shields - all of which offer good performance up to 200C.

These are used in conjunction with specially developed high-temperature greases, such as NSK's ENS-type, which functions reliably up to 160C, with other greases for operation up to 250C on request.

These greases are said to offer superior thermal stability and high-temperature durability, combined with long life and high temperatures.

Generally, internal clearances are designated from C1 (the smallest) through to C5 (the largest).

The 'normal' clearance is CN, a range sitting between C2 and C3.

NSK offers its high-temperature deep-groove ball bearings with C3 or C4 clearance, giving improved performance and longer lifetimes in applications with high temperatures or where large temperature differentials through the bearing are present.

Where the requirement is for bearing operation in excess of 200C, NSK offers the Spacea range of products.

These bearings redefine the operating parameters for high-temperature bearings in all areas of manufacturing and processing technology, with new materials and designs that provide high levels of performance in normal atmospheric and vacuum environments at temperatures up to 400C.

Next Schaeffler CSX Formed Thin-section Bearings

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.