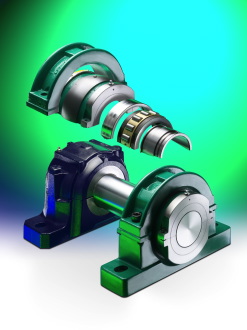

Reducing costs in all areas of industrial production is especially crucial in the present economic climate. Revolvo is providing this facility with its SRB SN and SD series of split roller bearings. These units offer direct dimensional interchangeabilty with standard plumber blocks that house solid bearings. Solid bearings take on average, eight- times longer to replace than split roller bearings; so by replacing trapped solid bearings with Revolvo’s SRB SN and SD series split bearings when failures occur, users can achieve drastic reductions in downtime costs.

The SRB SN & SD series of split roller bearing units effectively overcome the traditional problem of replacing standard plummer blocks with split roller units: that of the housing base to shaft centreline being higher on a split bearing, necessitating expensive modifications to machinery. They provide a simple bolt-on solution that offers full dimensional interchangeability with conventional plummer blocks, and require no structural changes to adjacent machinery.

The new bearings provide a revolution in downtime reduction and OEE. They are convenient and quick – up to 80% faster replacement time compared to solid bearings, vastly reducing the time required to change trapped bearings. In addition, they have a new design of cage clip, which is retained via roll pins to one half of the cage during assembly and disassembly. This is important, because lost bearing cage clips can halt production as effectively as any breakdown. However, with Revolvo’s unique design the maintenance engineer benefits from a “free hand”, which can only speed up the bearing replacement process.

In addition to their primary role of reducing downtime, Revolvo’s SRB split bearings offer users performance advantages not found with some solid bearings. First, SRB split bearings are designed to be statically self-aligning. This means that there is no need to accurately realign the bearing housing to the shaft or any other in-line equipment, which might be involved in the installation.

Second, SRB split bearings offer users much improved reliability, due to their ability to accommodate thermal expansion of the shaft efficiently within the bearing envelope.

Third, SRB split bearings perform reliably in high temperature environments, up to 140 oC for the standard bearings, and up to 300 deg C with special heat treatment. They are also ideal for use in aggressive environments, due to the high performance of the sealing systems available. In fact, the SRB product has inherent advantages over traditional solid bearings in the area of sealing. This is because the spherical location between the housing and support pedestal ensures that under conditions of shaft misalignment, the seals always remain concentric to the shaft. As a result, SRB split bearings perform exceptionally well in harsh operating conditions, even with shaft misalignment, whereas solid plummer block mounted bearings can suffer from non-concentric ineffective seals that will rapidly lead to expensive premature bearing failure.

Fourth and final, Revolvo’s SN and SD series split roller bearings satisfy the demands of specific industries where there is a requirement to inspect production critical bearings at regular intervals, as part of a planned maintenance campaign. Revolvo’s design makes this procedure a simple one. It provides “Pry” slots to enable easy disassembly of the housing & support pedestal, reducing the likelihood of components being broken, especially in applications where the bearing unit has been installed for some time; and/or where the environment is wet.

For further information, please contact:

Revolvo Ltd, Unit 4, Yorks Park, Blowers Green Road, Dudley, West Midlands, DY2 8UL Tel: +44 (0) 1384-245370 Fax: +44 (0) 1384-245371 Email: Adrian.Menzies@Revolvo.com Web: www.revolvo.com

Reducing costs in all areas of industrial production is especially crucial in the present economic climate. Revolvo is providing this facility with its SRB SN and SD series of split roller bearings. These units offer direct dimensional interchangeabilty with standard plumber blocks that house solid bearings. Solid bearings take on average, eight- times longer to replace than split roller bearings; so by replacing trapped solid bearings with Revolvo’s SRB SN and SD series split bearings when failures occur, users can achieve drastic reductions in downtime costs.

The SRB SN & SD series of split roller bearing units effectively overcome the traditional problem of replacing standard plummer blocks with split roller units: that of the housing base to shaft centreline being higher on a split bearing, necessitating expensive modifications to machinery. They provide a simple bolt-on solution that offers full dimensional interchangeability with conventional plummer blocks, and require no structural changes to adjacent machinery.

The new bearings provide a revolution in downtime reduction and OEE. They are convenient and quick – up to 80% faster replacement time compared to solid bearings, vastly reducing the time required to change trapped bearings. In addition, they have a new design of cage clip, which is retained via roll pins to one half of the cage during assembly and disassembly. This is important, because lost bearing cage clips can halt production as effectively as any breakdown. However, with Revolvo’s unique design the maintenance engineer benefits from a “free hand”, which can only speed up the bearing replacement process.

In addition to their primary role of reducing downtime, Revolvo’s SRB split bearings offer users performance advantages not found with some solid bearings. First, SRB split bearings are designed to be statically self-aligning. This means that there is no need to accurately realign the bearing housing to the shaft or any other in-line equipment, which might be involved in the installation.

Second, SRB split bearings offer users much improved reliability, due to their ability to accommodate thermal expansion of the shaft efficiently within the bearing envelope.

Third, SRB split bearings perform reliably in high temperature environments, up to 140 oC for the standard bearings, and up to 300 deg C with special heat treatment. They are also ideal for use in aggressive environments, due to the high performance of the sealing systems available. In fact, the SRB product has inherent advantages over traditional solid bearings in the area of sealing. This is because the spherical location between the housing and support pedestal ensures that under conditions of shaft misalignment, the seals always remain concentric to the shaft. As a result, SRB split bearings perform exceptionally well in harsh operating conditions, even with shaft misalignment, whereas solid plummer block mounted bearings can suffer from non-concentric ineffective seals that will rapidly lead to expensive premature bearing failure.

Fourth and final, Revolvo’s SN and SD series split roller bearings satisfy the demands of specific industries where there is a requirement to inspect production critical bearings at regular intervals, as part of a planned maintenance campaign. Revolvo’s design makes this procedure a simple one. It provides “Pry” slots to enable easy disassembly of the housing & support pedestal, reducing the likelihood of components being broken, especially in applications where the bearing unit has been installed for some time; and/or where the environment is wet.

For further information, please contact:

Revolvo Ltd, Unit 4, Yorks Park, Blowers Green Road, Dudley, West Midlands, DY2 8UL Tel: +44 (0) 1384-245370 Fax: +44 (0) 1384-245371 Email: Adrian.Menzies@Revolvo.com Web: www.revolvo.com

Next 3 Piece Metric Rod Ends from Aurora Bearing

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.