Tokyo, Japan, November 16, 2011 — NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed ultra-long-life ball bearings (EBR*) that will help make automotive transmissions more compact and lightweight, to contribute to improved fuel economy. NSK will aggressively promote this product to automobile manufacturers in Japan and overseas and expects annual sales to reach 3.5 billion yen in 2015.

NSK will exhibit this product at Tokyo Big Sight (located in Koto Ward in Tokyo) from Wednesday November 30 to Saturday December 11 at the Tokyo Motor Show 2011.

* EBR:Enhanced Bearing by Rolling element. A bearing in which a long service life is achieved by strengthening the rolling element

Development background

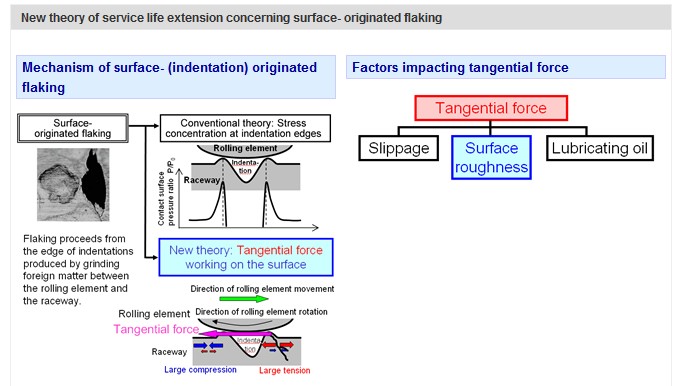

In recent years there has been demand to make automotive transmissions more compact, lightweight and more efficient in response to a worldwide tightening of fuel economy regulations. On the other hand, there is demand to make the bearings used in transmissions sufficiently durable to withstand surface-originated flaking (flaking that starts at the surface), since these bearings are used under harsh lubrication conditions. At the same time, the viscosity of transmission lubricating oil is expected to be lowered and the lubricating film made thinner with a view toward improving fuel economy, resulting in increasingly greater demands for bearing durability.

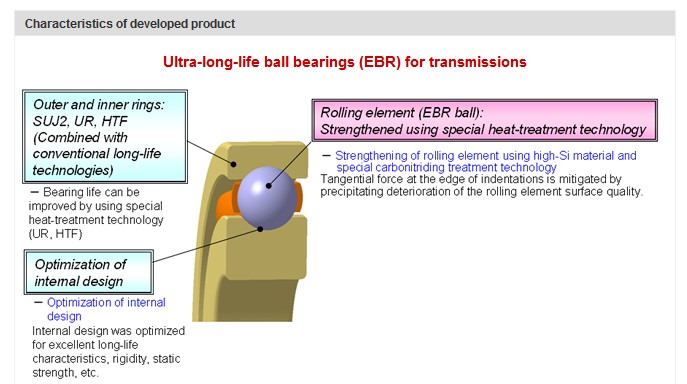

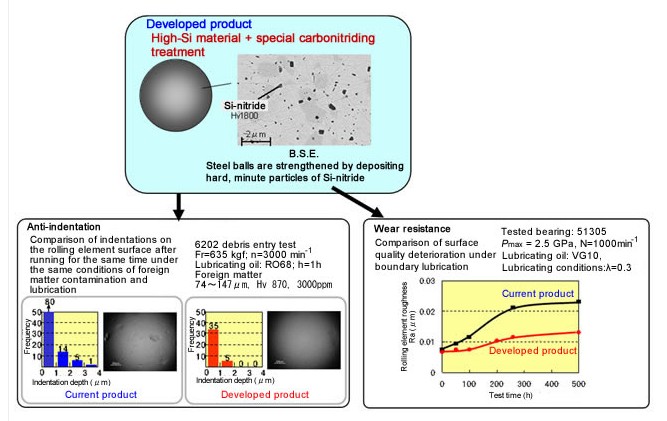

NSK carried out more thorough research into the mechanism of surface-originated flaking and discovered that bearing life can be further improved by strengthening the rolling element. Featuring dramatically increased durability achieved by strengthening the rolling element, the new product, combined with long-life technology cultivated thus far by NSK (TF technology), will contribute to the pursuit of more compact and lightweight transmissions, with less friction.

NSK will aggressively promote this product to automobile manufacturers in Japan and overseas.

Product features

Strengtherned rolling element

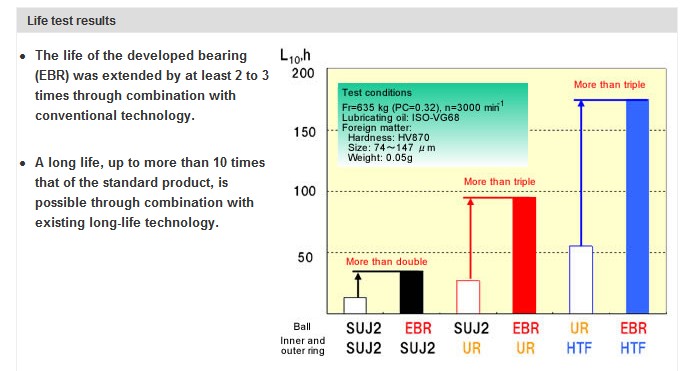

The surface of the rolling element in this product has been strengthened by optimizing the material composition and applying TF technology, greatly inhibiting the deterioration of surface quality during use and thereby enabling a service life that is two to three times longer than usual.

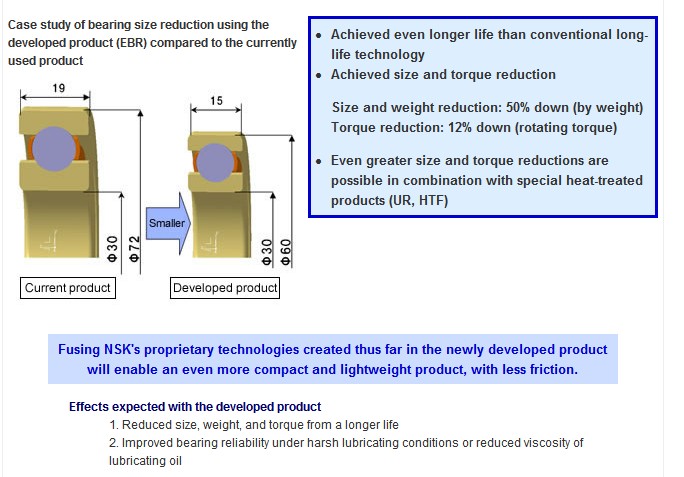

More compact and lightweight bearing

By combining NSK's proprietary long-life technology (TF technology), the service life can be improved by more than 10 times that of the standard product, while the more compact and lightweight bearing will contribute greatly to reducing friction. The basic technology used in the materials in this product was developed by NSK’s research institute. Going forward, NSK will continue to apply the four core technologies the company has cultivated for over 90 years (tribology, material engineering, analysis technology, and mechatronics) to develop products that help create more compact and lightweight automobiles, with less friction, thereby improving automotive fuel economy.

The basic technology used in the materials in this product was developed by NSK’s research institute. Going forward, NSK will continue to apply the four core technologies the company has cultivated for over 90 years (tribology, material engineering, analysis technology, and mechatronics) to develop products that help create more compact and lightweight automobiles, with less friction, thereby improving automotive fuel economy.

Tokyo, Japan, November 16, 2011 — NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed ultra-long-life ball bearings (EBR*) that will help make automotive transmissions more compact and lightweight, to contribute to improved fuel economy. NSK will aggressively promote this product to automobile manufacturers in Japan and overseas and expects annual sales to reach 3.5 billion yen in 2015.

NSK will exhibit this product at Tokyo Big Sight (located in Koto Ward in Tokyo) from Wednesday November 30 to Saturday December 11 at the Tokyo Motor Show 2011.

* EBR:Enhanced Bearing by Rolling element. A bearing in which a long service life is achieved by strengthening the rolling element

Development background

In recent years there has been demand to make automotive transmissions more compact, lightweight and more efficient in response to a worldwide tightening of fuel economy regulations. On the other hand, there is demand to make the bearings used in transmissions sufficiently durable to withstand surface-originated flaking (flaking that starts at the surface), since these bearings are used under harsh lubrication conditions. At the same time, the viscosity of transmission lubricating oil is expected to be lowered and the lubricating film made thinner with a view toward improving fuel economy, resulting in increasingly greater demands for bearing durability.

NSK carried out more thorough research into the mechanism of surface-originated flaking and discovered that bearing life can be further improved by strengthening the rolling element. Featuring dramatically increased durability achieved by strengthening the rolling element, the new product, combined with long-life technology cultivated thus far by NSK (TF technology), will contribute to the pursuit of more compact and lightweight transmissions, with less friction.

NSK will aggressively promote this product to automobile manufacturers in Japan and overseas.

Product features

Strengtherned rolling element

The surface of the rolling element in this product has been strengthened by optimizing the material composition and applying TF technology, greatly inhibiting the deterioration of surface quality during use and thereby enabling a service life that is two to three times longer than usual.

More compact and lightweight bearing

By combining NSK's proprietary long-life technology (TF technology), the service life can be improved by more than 10 times that of the standard product, while the more compact and lightweight bearing will contribute greatly to reducing friction. The basic technology used in the materials in this product was developed by NSK’s research institute. Going forward, NSK will continue to apply the four core technologies the company has cultivated for over 90 years (tribology, material engineering, analysis technology, and mechatronics) to develop products that help create more compact and lightweight automobiles, with less friction, thereby improving automotive fuel economy.

The basic technology used in the materials in this product was developed by NSK’s research institute. Going forward, NSK will continue to apply the four core technologies the company has cultivated for over 90 years (tribology, material engineering, analysis technology, and mechatronics) to develop products that help create more compact and lightweight automobiles, with less friction, thereby improving automotive fuel economy.

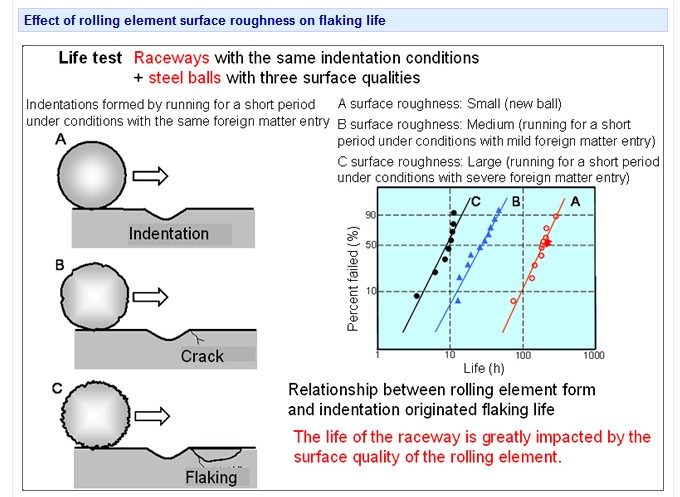

When the rolling element's surface roughness worsens, the tangential force acting on the edge of indentations in the raceway increases, causing the rolling fatigue life to decrease. → Service life can be extended by inhibiting the deterioration of the rolling element's surface quality.

When the rolling element's surface roughness worsens, the tangential force acting on the edge of indentations in the raceway increases, causing the rolling fatigue life to decrease. → Service life can be extended by inhibiting the deterioration of the rolling element's surface quality.

Next MPS Prodige Ball Bearing

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.