NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a new series of dental air-turbine* bearings for application in dental handpieces. This new series achieves 1.5 times the life and 10 times the corrosion resistance of conventional bearings in the application of air-driven dental handpieces. NSK is targeting 1 billion yen in global annual sales for this series in 2017.

* Dental air turbine: Dental instrument that is driven by air and providing high speeds to grind teeth.

Development Background

Dental air turbine bearings reach speeds of 400,000 rpm. As such, regular maintenance and bearing replacement are required, which has resulted in a demand for longer bearing life. Also, after each use, the bearings are exposed to the harsh conditions of cleaning solutions, high pressure and temperature during the sterilization process. Therefore, such bearings also need a high level of corrosion resistance and durability.

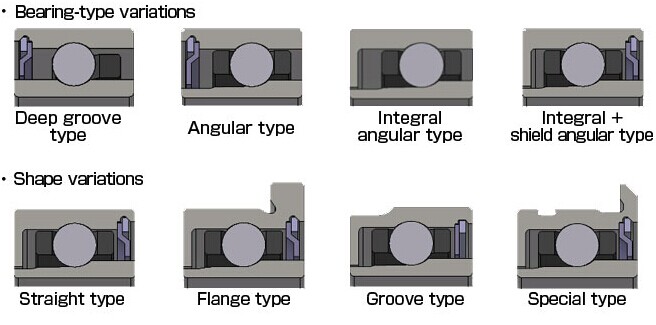

In the development of this new series of bearings, NSK used high-corrosion-resistant material that it developed using one of its core technologies of material engineering, along with advanced component design and processing technology to achieve 1.5 times the life of conventional bearings. In addition, knowing that there are many types, shapes and sizes of bearings used in the air-turbine market, NSK developed a wide-ranging variety for this series.

Product Features

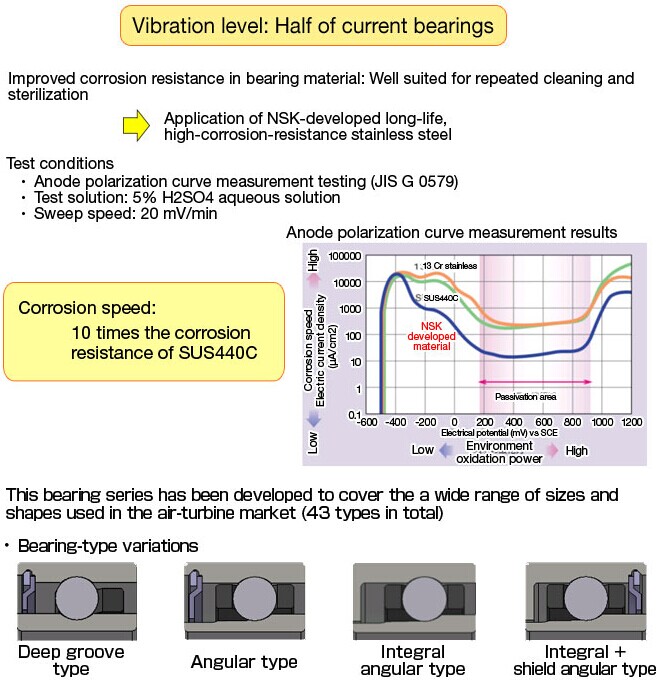

NSK optimized the design of the bearing cage and improved the precision of its processing component to reduce the level of vibration, thereby making it possible to achieve 1.5 times the life of conventional bearings. Further, NSK used its proprietary long-life, high-corrosion-resistant stainless steel to achieve 10 times the corrosion resistance of the material typically used to make air-turbine bearings.

1. 1.5 times the life (while maintaining super high speeds)

2. Half the vibration level

3. 10 times the corrosion resistance

4. Wide variety in product lineup

Product Benefits

1. High reliability for longer interval between maintenance operations

2. Lower vibration for less pain during grinding

3. Helps maintain safe and reliable sterilization for clean and comfortable treatment conditions

4. Meets a variety of market needs

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a new series of dental air-turbine* bearings for application in dental handpieces. This new series achieves 1.5 times the life and 10 times the corrosion resistance of conventional bearings in the application of air-driven dental handpieces. NSK is targeting 1 billion yen in global annual sales for this series in 2017.

* Dental air turbine: Dental instrument that is driven by air and providing high speeds to grind teeth.

Development Background

Dental air turbine bearings reach speeds of 400,000 rpm. As such, regular maintenance and bearing replacement are required, which has resulted in a demand for longer bearing life. Also, after each use, the bearings are exposed to the harsh conditions of cleaning solutions, high pressure and temperature during the sterilization process. Therefore, such bearings also need a high level of corrosion resistance and durability.

In the development of this new series of bearings, NSK used high-corrosion-resistant material that it developed using one of its core technologies of material engineering, along with advanced component design and processing technology to achieve 1.5 times the life of conventional bearings. In addition, knowing that there are many types, shapes and sizes of bearings used in the air-turbine market, NSK developed a wide-ranging variety for this series.

Product Features

NSK optimized the design of the bearing cage and improved the precision of its processing component to reduce the level of vibration, thereby making it possible to achieve 1.5 times the life of conventional bearings. Further, NSK used its proprietary long-life, high-corrosion-resistant stainless steel to achieve 10 times the corrosion resistance of the material typically used to make air-turbine bearings.

1. 1.5 times the life (while maintaining super high speeds)

2. Half the vibration level

3. 10 times the corrosion resistance

4. Wide variety in product lineup

Product Benefits

1. High reliability for longer interval between maintenance operations

2. Lower vibration for less pain during grinding

3. Helps maintain safe and reliable sterilization for clean and comfortable treatment conditions

4. Meets a variety of market needs

Next Haydon Kerk Offers Micros Screws for Specialized Medical Devices

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.