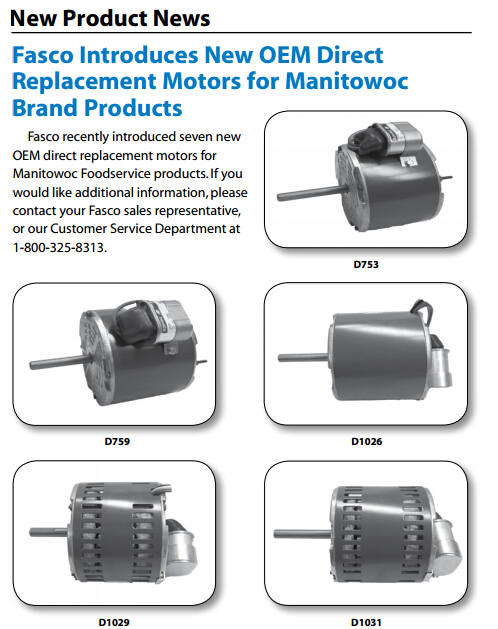

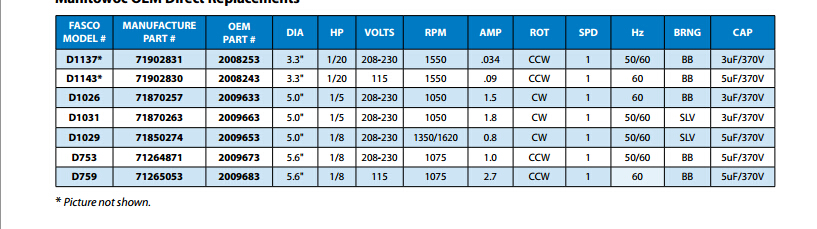

Fasco Introduces New OEM Direct Replacement Motors for Manitowoc Brand Products New Product News Fasco recently introduced seven new OEM direct replacement motors for Manitowoc Foodservice products. If you would like additional information, please contact your Fasco sales representative,or our Customer Service Department at1-800-325-8313.

Tech Tips

The Importance of Proper Lubrication – and

Mounting – of Motors with Rigid Sleeve Bearings

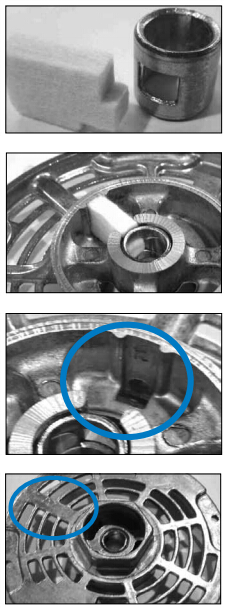

Babbitt-lined, steel-backed sleeve bearings are quiet, long life bearings capable of operating heavier direct drive air moving loads. They are most frequently used in motors with diameters exceeding 5". They’re also very popular in 48 Frame motors because of their long life and hefty load carrying capacity. These bearings are pressed into a die-cast end shield for maximum support and heat dissipation. Due to

the solid contact with the end shield, they dissipate heat better than

self-aligning bearings.In rigid bearing systems, oil is transferred from the oil reservoir to the shaft surface by a felt wick that

extends through a window in the bearing, typically known as a wick

window. The wick allows the oil to flow from the reservoir, through the wick, to the shaft surface. As the shaft rotates, a lubricating film is developed between the shaft and bearing.The system also includes an oil slinger (rubber washer) to return any oil that travels down the shaft to the reservoir. The slinger is ineffective

at speeds below 500 RPM because oil can seep out between the shaft

and bearing, causing severe loss of lubricant. Wind milling (which happens, for example, when a warehouse side wall ventilator, while shut off, slowly spins due to outside wind blowing through it) may actually deplete the oil from a bearing system in a short

period of time. Rigid sleeve bearings also introduce one limit to “All Angle” mounting. The surface area of the bearing is reduced

at the window location, which also reduces the load capacity in this

quadrant of the bearing. Therefore,extreme care should be taken to avoid loading the motor in the direction of the wick window. This includes mounting the motor with the windows in the downward position in a shaft horizontal fan unit. Doing so can reduce the life of the motor significantly. The wick window is located at the

re-oiling location. If the motor does not include an oil hole or removable plug, the wick window is located atthe end of the widest rib in the motor end bracket. The general rule of thumb is to be certain to mount the motor in the unit so the oil hole or widest rib is always within 60 degrees of straight up.

Tech Tips

The Importance of Proper Lubrication – and

Mounting – of Motors with Rigid Sleeve Bearings

Babbitt-lined, steel-backed sleeve bearings are quiet, long life bearings capable of operating heavier direct drive air moving loads. They are most frequently used in motors with diameters exceeding 5". They’re also very popular in 48 Frame motors because of their long life and hefty load carrying capacity. These bearings are pressed into a die-cast end shield for maximum support and heat dissipation. Due to

the solid contact with the end shield, they dissipate heat better than

self-aligning bearings.In rigid bearing systems, oil is transferred from the oil reservoir to the shaft surface by a felt wick that

extends through a window in the bearing, typically known as a wick

window. The wick allows the oil to flow from the reservoir, through the wick, to the shaft surface. As the shaft rotates, a lubricating film is developed between the shaft and bearing.The system also includes an oil slinger (rubber washer) to return any oil that travels down the shaft to the reservoir. The slinger is ineffective

at speeds below 500 RPM because oil can seep out between the shaft

and bearing, causing severe loss of lubricant. Wind milling (which happens, for example, when a warehouse side wall ventilator, while shut off, slowly spins due to outside wind blowing through it) may actually deplete the oil from a bearing system in a short

period of time. Rigid sleeve bearings also introduce one limit to “All Angle” mounting. The surface area of the bearing is reduced

at the window location, which also reduces the load capacity in this

quadrant of the bearing. Therefore,extreme care should be taken to avoid loading the motor in the direction of the wick window. This includes mounting the motor with the windows in the downward position in a shaft horizontal fan unit. Doing so can reduce the life of the motor significantly. The wick window is located at the

re-oiling location. If the motor does not include an oil hole or removable plug, the wick window is located atthe end of the widest rib in the motor end bracket. The general rule of thumb is to be certain to mount the motor in the unit so the oil hole or widest rib is always within 60 degrees of straight up.

Next Zero-Max ETP-EXPAND Improves Pump Drive Connection

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.