This article was originally published in the April issue of COMPRESSORtech2. Get every issue in your inbox/mailbox and access to our digital archives with a free subscription.

Lars Kahlman knows that materials matter when it comes to bearings and machine performance. The trick is finding the balance between saving money and using expensive materials to prolong bearing and machine life. When expensive materials are used in the right way in the right applications, performance improves and costs are kept down.

“Everybody likes a bargain, but it is often worth paying more in the short term in order to reap long-term benefits,” said Kahlman, senior application expert at SKF. “How many times have we gone for a cheaper option and bemoaned the ‘false economy’ later? Buying more expensive components and materials is not always the answer; however, being selective about when to use them can help to optimize designs, and extend the lifetime of both machinery and components.”

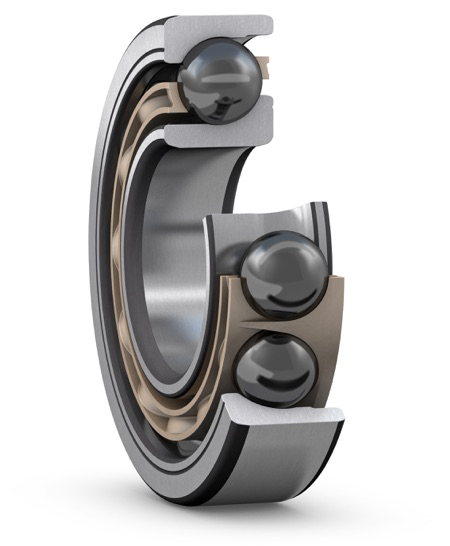

Those premium materials include silicon nitride, stainless steal and polyetheretherketone (PEEK). Silicon nitride is used in rolling elements in “hybrid” bearings. Stainless steel is used for bearing rings and PEEK is a high-temperature plastic that can be used to make bearing cages. Using those materials can help prolong the life of bearings and improve machine performance, according to SKF.

The ceramic material, silicon nitride (Si3N4), has become widely adopted in bearing rolling elements. These bearings are so-called hybrid bearings because the ceramic silicon nitride combines with the conventional metal used in the bearing rings. Silicon nitride is often used to improve the performance of a bearing, allowing higher speeds and better electrical insulation. It can also be used in poorly lubricated applications. In many cases, a silicon nitride-rolling element would be used to “fix” a poorly performing bearing arrangement.

However, if it is originally designed into the bearing, it is also increasingly used as an “enabler.” In these cases, instead of solving an existing problem, it takes the bearing to a new level of performance. The hybrid rolling bearings work very well over a broad speed range; e.g., at slow speeds that cause poor lubrication and at normal and high speeds with less centrifugal force and higher grease-life.

Generally, the hybrid bearings continue to work even if the grease starts to degrade — especially at high speeds — and also withstand contamination better. Hybrids even inhibit vibration damage in machines standing still as backup. Hybrid bearings are already widely used in machine tools, thanks to their ability to run at high speed. However, their electrical properties make them useful for variable speed drives, where they are making inroads.

“As production volumes rise and prices drop, they will also find their way into more mass-market applications, such as automotive,” Kahlman said. “In particular, the advent of the electrical drivetrain will probably see a huge rise in the use of hybrid bearings in this industry.”

Super-tough, stainless-steel bearings still lag behind the well-established hybrids, SKF said. Hybrid bearings were introduced to the market some 20 years ahead of the super-tough stainless-steel material, which can be used to make bearing rings with greater mechanical strength and fatigue resistance.

So far, this material has been targeted at niche applications in the machine tools, aerospace and fluid machinery sectors. When choosing a material for a bearing, there is often a trade-off between two competing properties: corrosion resistance and fatigue performance. Super-tough stainless steel can be used to make bearing rings, which offer both properties at the same time.

“We see several promising applications here, including a central role in so-called PRL (pure refrigerant lubrication) compressors, which are a new breed of compressors in which the refrigerant doubles up as the bearing lubricant,” Kahlman said. “Usually, this arrangement would require the bearing to be isolated or work in a refrigerant-oil mixture, and consequently, much more complex designs. The new material is robust enough to resist both corrosion and fatigue, meaning the whole design could be simplified.”

It may seem counter intuitive to replace metal with plastics, but in many cases a high-performance engineering plastic will have several advantages over metals. The most obvious is the weight savings it brings to the design. However, an often-overlooked aspect of plastic is the ease of production. A plastic part, once designed, can easily be produced in large volumes using injection molding, which helps to shrink manufacturing costs.

PEEK is a semi crystalline, high-temperature (up to 500°F [260°C]) engineering thermoplastic, which is excel- lent for applications where thermal, chemical, and combustion properties are critical to performance. This material is tough, strong, and rigid and has superior creep resistance. It also resists radiation and a wide range of solvents. PEEK resins are available in unreinforced, and a wide range of various fiber reinforced grades. A 15% glass fiber fill grade is the most common for rolling bearings. PEEK is widely use in various compressor parts seeing sour and acid gases.

SKF has used glass-reinforced PEEK to make complex bearing cages in place of steel or brass. They can be designed to withstand a temperature range from -328°F to 302°F (-200°C to 150°C) or more.

“PEEK can be used very broadly in bearing applications ranging from gearboxes to machine tools,” Kahlman said. “In gearboxes, for example, PEEK has also begun to replace polyamide. Gearboxes use very aggressive gear oils that are running at high temperatures, yet PEEK is able to resist their effects.”

Together, these three materials have made inroads into full industrial use. The earliest examples were punishing applications within the oil and gas industry. For instance, SKF developed a set of “sour gas” bearings to replace all-steel bearings in a vapor recovery unit. These bearings use all three of these advanced materials discussed earlier and were shown to last more than 10 times longer than those they replaced. In similar fashion, the same three materials were used to design cryogenic pump bearings for use with liquefied natural gas (LNG).

“These applications mentioned here are at the top end of the performance scale,” Kahlman said. “However, the materials are finding their way into more general applications, from high-power stone-working equipment to new generations of high-efficiency chillers. As these materials become more widely accepted, SKF expects to see them on a host of industrial applications, where, when used correctly, they will deliver maximum efficiency and cost savings.”

This article was originally published in the April issue of COMPRESSORtech2. Get every issue in your inbox/mailbox and access to our digital archives with a free subscription.

Lars Kahlman knows that materials matter when it comes to bearings and machine performance. The trick is finding the balance between saving money and using expensive materials to prolong bearing and machine life. When expensive materials are used in the right way in the right applications, performance improves and costs are kept down.

“Everybody likes a bargain, but it is often worth paying more in the short term in order to reap long-term benefits,” said Kahlman, senior application expert at SKF. “How many times have we gone for a cheaper option and bemoaned the ‘false economy’ later? Buying more expensive components and materials is not always the answer; however, being selective about when to use them can help to optimize designs, and extend the lifetime of both machinery and components.”

Those premium materials include silicon nitride, stainless steal and polyetheretherketone (PEEK). Silicon nitride is used in rolling elements in “hybrid” bearings. Stainless steel is used for bearing rings and PEEK is a high-temperature plastic that can be used to make bearing cages. Using those materials can help prolong the life of bearings and improve machine performance, according to SKF.

The ceramic material, silicon nitride (Si3N4), has become widely adopted in bearing rolling elements. These bearings are so-called hybrid bearings because the ceramic silicon nitride combines with the conventional metal used in the bearing rings. Silicon nitride is often used to improve the performance of a bearing, allowing higher speeds and better electrical insulation. It can also be used in poorly lubricated applications. In many cases, a silicon nitride-rolling element would be used to “fix” a poorly performing bearing arrangement.

However, if it is originally designed into the bearing, it is also increasingly used as an “enabler.” In these cases, instead of solving an existing problem, it takes the bearing to a new level of performance. The hybrid rolling bearings work very well over a broad speed range; e.g., at slow speeds that cause poor lubrication and at normal and high speeds with less centrifugal force and higher grease-life.

Generally, the hybrid bearings continue to work even if the grease starts to degrade — especially at high speeds — and also withstand contamination better. Hybrids even inhibit vibration damage in machines standing still as backup. Hybrid bearings are already widely used in machine tools, thanks to their ability to run at high speed. However, their electrical properties make them useful for variable speed drives, where they are making inroads.

“As production volumes rise and prices drop, they will also find their way into more mass-market applications, such as automotive,” Kahlman said. “In particular, the advent of the electrical drivetrain will probably see a huge rise in the use of hybrid bearings in this industry.”

Super-tough, stainless-steel bearings still lag behind the well-established hybrids, SKF said. Hybrid bearings were introduced to the market some 20 years ahead of the super-tough stainless-steel material, which can be used to make bearing rings with greater mechanical strength and fatigue resistance.

So far, this material has been targeted at niche applications in the machine tools, aerospace and fluid machinery sectors. When choosing a material for a bearing, there is often a trade-off between two competing properties: corrosion resistance and fatigue performance. Super-tough stainless steel can be used to make bearing rings, which offer both properties at the same time.

“We see several promising applications here, including a central role in so-called PRL (pure refrigerant lubrication) compressors, which are a new breed of compressors in which the refrigerant doubles up as the bearing lubricant,” Kahlman said. “Usually, this arrangement would require the bearing to be isolated or work in a refrigerant-oil mixture, and consequently, much more complex designs. The new material is robust enough to resist both corrosion and fatigue, meaning the whole design could be simplified.”

It may seem counter intuitive to replace metal with plastics, but in many cases a high-performance engineering plastic will have several advantages over metals. The most obvious is the weight savings it brings to the design. However, an often-overlooked aspect of plastic is the ease of production. A plastic part, once designed, can easily be produced in large volumes using injection molding, which helps to shrink manufacturing costs.

PEEK is a semi crystalline, high-temperature (up to 500°F [260°C]) engineering thermoplastic, which is excel- lent for applications where thermal, chemical, and combustion properties are critical to performance. This material is tough, strong, and rigid and has superior creep resistance. It also resists radiation and a wide range of solvents. PEEK resins are available in unreinforced, and a wide range of various fiber reinforced grades. A 15% glass fiber fill grade is the most common for rolling bearings. PEEK is widely use in various compressor parts seeing sour and acid gases.

SKF has used glass-reinforced PEEK to make complex bearing cages in place of steel or brass. They can be designed to withstand a temperature range from -328°F to 302°F (-200°C to 150°C) or more.

“PEEK can be used very broadly in bearing applications ranging from gearboxes to machine tools,” Kahlman said. “In gearboxes, for example, PEEK has also begun to replace polyamide. Gearboxes use very aggressive gear oils that are running at high temperatures, yet PEEK is able to resist their effects.”

Together, these three materials have made inroads into full industrial use. The earliest examples were punishing applications within the oil and gas industry. For instance, SKF developed a set of “sour gas” bearings to replace all-steel bearings in a vapor recovery unit. These bearings use all three of these advanced materials discussed earlier and were shown to last more than 10 times longer than those they replaced. In similar fashion, the same three materials were used to design cryogenic pump bearings for use with liquefied natural gas (LNG).

“These applications mentioned here are at the top end of the performance scale,” Kahlman said. “However, the materials are finding their way into more general applications, from high-power stone-working equipment to new generations of high-efficiency chillers. As these materials become more widely accepted, SKF expects to see them on a host of industrial applications, where, when used correctly, they will deliver maximum efficiency and cost savings.”

Next Timken Named One of America's Best Large Employers by Forbes

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.