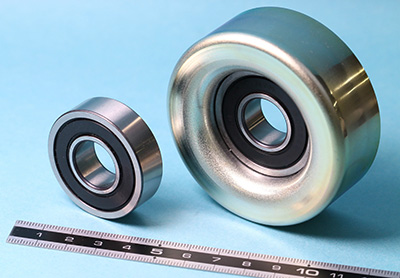

Corresponding to outer ring rotation 20,000min-1 with 6203 size

NTN Corporation (hereafter, NTN) has developed a bearing for pulleys achieving to rotate at up to 20,000 min-1 (approximately 1.3 times NTN's conventional products) in outer ring rotating by optimizing the internal bearing design and structural components.

Bearings for pulleys used in automotive engine accessory belts are required to meet demand of restrictions in mounting layouts due to the increasing complex layout of engine accessories, as a result of smaller engine sizes with recent downsizing technology and an increase in the number of automobiles equipped with ISG *1. A smaller pulley diameter allows for wider space for the mounting lay out, however a smaller pulley diameter also requires the pulley bearing realizing high-speed rotating performance. To enhance comfort and reliability of automobiles, there is demand for pulley bearings that operate without hoot noise when running cold and that are capable of lower torque, which means even more advanced functionality is required.

The developed “High Speed Rotation Ball Bearing for Pulley” feature retainers and seals capable of handling the rotating centrifugal force, which limits heat generated at the seal lip when rotating at high- speed as well as preventing retainer deformation, making them capable of rotating at 20,000 min-1, approximately 1.3 times compared to conventional products. Adopting the grease functioning effectively at the low-temperature also prevents the grease becoming hard at low temperatures and limits hoot noise when running cold that are caused by vibrations between the bearing outer ring and pulley. Using grease additives which slow down damage caused by brittle flaking, which is one of the factors for damage to bearings, and improving heat treatment to enhances low-temperature characteristics of bearing raceway while maintaining protection against brittle flaking. Optimizations made to the seal shape, grease base oil and internal specifications limit the amount of torque applied to seals and stirring resistance of grease, which has also led to a 10% reduction in rotational torque compared to conventional products.

NTN will propose the newly developed “High Speed Rotation Ball Bearing for Pulley” globally and release it in markets, to help customers requiring faster and more compact pulleys with a higher level of functionality. NTN exhibited the developed product at the “Automotive Engineering Exposition 2017” held at Pacifico Yokohama from May 24 to 26.

Corresponding to outer ring rotation 20,000min-1 with 6203 size

NTN Corporation (hereafter, NTN) has developed a bearing for pulleys achieving to rotate at up to 20,000 min-1 (approximately 1.3 times NTN's conventional products) in outer ring rotating by optimizing the internal bearing design and structural components.

Bearings for pulleys used in automotive engine accessory belts are required to meet demand of restrictions in mounting layouts due to the increasing complex layout of engine accessories, as a result of smaller engine sizes with recent downsizing technology and an increase in the number of automobiles equipped with ISG *1. A smaller pulley diameter allows for wider space for the mounting lay out, however a smaller pulley diameter also requires the pulley bearing realizing high-speed rotating performance. To enhance comfort and reliability of automobiles, there is demand for pulley bearings that operate without hoot noise when running cold and that are capable of lower torque, which means even more advanced functionality is required.

The developed “High Speed Rotation Ball Bearing for Pulley” feature retainers and seals capable of handling the rotating centrifugal force, which limits heat generated at the seal lip when rotating at high- speed as well as preventing retainer deformation, making them capable of rotating at 20,000 min-1, approximately 1.3 times compared to conventional products. Adopting the grease functioning effectively at the low-temperature also prevents the grease becoming hard at low temperatures and limits hoot noise when running cold that are caused by vibrations between the bearing outer ring and pulley. Using grease additives which slow down damage caused by brittle flaking, which is one of the factors for damage to bearings, and improving heat treatment to enhances low-temperature characteristics of bearing raceway while maintaining protection against brittle flaking. Optimizations made to the seal shape, grease base oil and internal specifications limit the amount of torque applied to seals and stirring resistance of grease, which has also led to a 10% reduction in rotational torque compared to conventional products.

NTN will propose the newly developed “High Speed Rotation Ball Bearing for Pulley” globally and release it in markets, to help customers requiring faster and more compact pulleys with a higher level of functionality. NTN exhibited the developed product at the “Automotive Engineering Exposition 2017” held at Pacifico Yokohama from May 24 to 26.

Next R+W Introduces CHB Belt Drive for Parallel Assemblies of Motors and Actuators

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.