Voith introduces Dtect, its intelligent monitoring system that provides real-time data of driveline performance and coupling status. Based on this, the operator can take actions to prevent potential problems and avoid unplanned downtime. By supporting better decision making, Dtect helps to increase productivity as well as significantly lower production and maintenance costs.

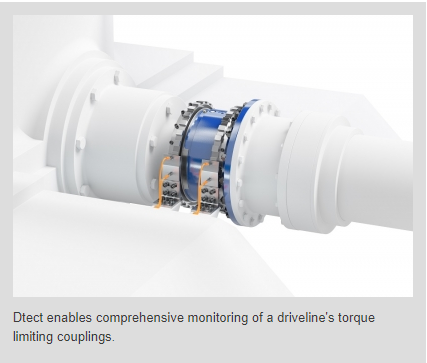

Dtect enables comprehensive monitoring of a driveline's torque limiting couplings. It was specifically designed to work with couplings, such as Voith’s SmartSet, which serve to prevent machine damage in high-value rotating equipment. It is also possible to upgrade existing couplings with this intelligent system.

Slippage monitoring for maximized uptime

Through continuous measurement of the slip angle, Dtect accurately identifies and monitors coupling slippage caused by high torque peaks in a driveline. This allows operators to take action if necessary, for example by adjusting the load of the driveline or by performing a controlled shutdown. As a result, operators will experience increased uptime, reduced maintenance and lower spare parts cost.

Data analysis ensures optimum performance

Dtect continuously collects driveline performance data that can be analyzed to ensure maximum productivity. It uses an updated quadruple sensor setup that increases the sensing range without affecting the resolution of the expanded measurement. By analyzing the slip behavior of the coupling, the operator can evaluate if the system is running at full capacity and, if not, adjust the parameters accordingly. Further, proactive coupling maintenance can be performed to avoid costly downtime.

Simultaneous monitoring through a single interface

Dtect now makes it possible to monitor multiple couplings at the same time. It assesses each coupling individually and communicates the multiple data streams to the common interface. In this way, Dtect allows for simultaneous monitoring of all connected drivelines. Operators benefit from comprehensive, real-time status information provided by one central system.

Easy integration for platform-independent data monitoring

Equipped with Modbus TCP/IP communications, Dtect is easily integrated into established process information networks. Given its high flexibility, the system can be adopted with ease to other communication standards to fit a wide range of requirements.

HMI touch panel for outstanding ease-of-use

Dtect can be fitted with an integrated HMI touch panel. It offers the highest usability, better control and status information at a glance. With visual warning indicators, the system assists operators in making decisions and taking the necessary actions in any given situation.

Next NB Corporation Offers Exrail for Linear Guides

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.