Claude Maack argues that light weight is equal to sustainability

Most governments in industrial leading countries have understood that we could not continue with an economy driven only based on growth. Thankfully in the past few years, the slowing down of the economy has offered us the opportunity to reflect on ourselves and to change things with regards to our responsibility towards our children and the next generations.

Knowing that the increasing demand for energy and resources in all its forms worldwide will not help to solve the problem, our society is forced to change things – and to change them now.

Although decarbonising the electricity production will be realised with renewables, nuclear and gas in the coming decades, the curve of the increasing energy demand must be flattened.

Lightweight construction is a big part of the solution. Light weighting is a needed process in many applications. It is concerning to the whole mobility sector and is concerning all things that move in industry (e.g. industrial robots carrying larger than needed EOAT).

The added value of lightweight construction is not easy to be understood or recognised by end-customers and politics, as you cannot touch it. Light weight as such is already sustainable because fewer primary resources are used during manufacturing and less energy will be consumed during usage.

When adding the aspect of the CO2 footprint of the whole process, starting with how to exploit resources from the ground (such as lithium for batteries) to the process of manufacturing of a whole vehicle, as well as continued energy consumption during product usage, by taking into account the energy mix of the electric grid and, last but not least, how to revalorise the materials used with regards to the circular economy aspect, it is complex to make the difference. Therefore, a standardised tool for measuring the sustainability index and thus reduce the complexity down to a level that could be understood by decision makers and stakeholders will help in future.

By knowing that aluminium has a high CO2 footprint compared to steel and that carbon fibres have a CO2 footprint that is eight times higher compared to basalt fibres, it is not easy for a decision maker to evaluate if the electric vehicle he wants to buy is now good or bad for saving the planet.

Thus, decision makers are not tackling the root of the problem when deciding to tax CO2 only. Taxing the mass of a vehicle would be better. Considering the CO2 footprint of the whole process chain – from resources, logistics, manufacturing to usage and recycling –will really target what we want all: being responsible with resources for our future generations.

New Approach To A Car Seat

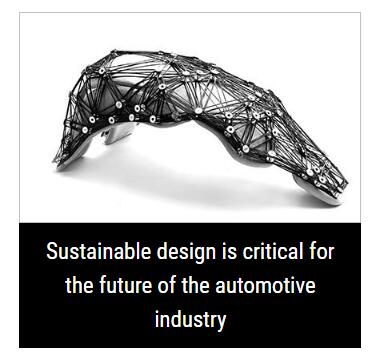

The proof-of-concept car seat that is described in this article has been designed according to the current highest sustainable criteria, something confirmed by several responsible OEMs.

Basalt is an excellent candidate for replacing carbon fibres, even for structural applications. The weight is higher, but due to the innovative process technology of endless wet winding fibre, the material is used only in the exact needed quantity. The simulation-driven process is very efficient and during production the waste is limited to almost nothing (no off-cut).

The highly innovative design, using a double layer truss structure provides a high stiffness for meeting the criteria of the standards and requirements to be considered for homologation of the respective market segment (e.g. automotive or aeronautic).

Using sustainable materials for the upholstery and as well as a back-panel of basalt, the future development will concentrate on replacing the already ~70% bio-based resin with a 100% bio-based resin, meeting the criteria for circular economy.

By designing future components consequently in that direction, a number of positive results can be achieved, including using fewer primary resources; lowering the primary energy consumption; and optimising the global CO2 footprint. This approach also considers the whole process chain including logistics. It tackles the issue of reduction of energy consumption during usage and it also considers the circular economy.

We will increase the chance to save the planet. It is only a part of the puzzle of course, but a very important one. In conclusion, lightweight is equal to sustainability with respect to the above-mentioned aspects.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.