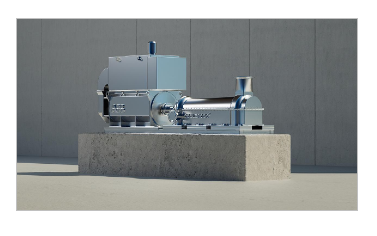

Coolbrook has launched its Roto Dynamic Heater (RDH) technology that uses electrification to remove the need for the burning of fossil fuels in the highest-emitting industrial processes. Powered by electricity from renewable sources, the firm believes that the RDH is the only process heating technology that can cut up to 30% of industrial CO2 emissions and over 7% of global CO2 emissions annually.

The RDH technology has been successfully tested in a pilot project in Finland and will be available for commercial use at scale in 2024. Cemex, a global leader in building materials, is the first company to announce it aims to use the technology to significantly reduce CO2 emissions from cement production. This comes in addition to Coolbrook’s existing partnerships with ABB and Shell.

How the technology works

Industrial CO2 emissions originate primarily from three main sectors: petrochemicals and chemicals; iron and steel; and cement production. The RDH, powered by electricity from renewable sources, can achieve process temperatures of up to around 1,700ºC with high energy efficiency and can thereby be used in processes that were impossible to electrify up until now. It makers believe that this is the only electric technology able to reach temperature levels required in the highest-emitting industrial sectors such as petrochemicals and chemicals, iron and steel and cement. Due to its compact size, the unit can also be retro-fitted to existing facilities and thereby significantly accelerate the much needed CO2 emission reduction investments.

The technology has been in development for over a decade and marks the second major technology developed by Coolbrook after its Roto Dynamic Reactor (RDR), which can be used to electrify the steam cracking process in the petrochemical industry.

Ilpo Kuokkanen, executive chairman of Coolbrook, said: “Today marks the beginning of a new industrial era. We have set a target to build a committed and comprehensive ecosystem around our technology to commercialise it as soon as possible. Together with ABB, Cemex, Shell and our other partners in industry, academia, public sector and among key decision-makers we can roll out this technology and achieve significant emission reductions in the most energy and CO2 intensive industrial processes that have been considered impossible to electrify.”

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.