Jeff Earl explains how a high-efficiency turboexpander-generator uses advanced magnetic technologies to enable waste-pressure energy recovery

Natural gas networks around the world use Joule-Thomson (J-T) valves to reduce line pressure upstream of city gas distribution. These mechanical valves are effective, but they generate significant amounts of waste-pressure energy, which can be captured and converted to electric power in a turboexpander-generator (TEG).

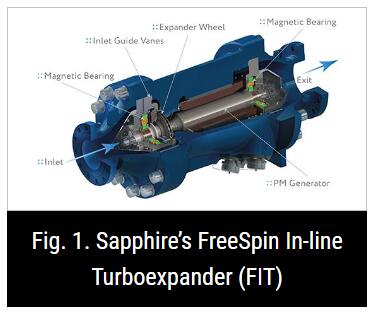

To that end, Sapphire Technologies (Sapphire), a spinoff from US-based Calnetix Technologies, has developed and deployed an integrated high-speed TEG system operating on advanced magnetic technologies. The system efficiently converts waste-pressure energy into electricity, which can be used locally

or sold back to the grid.

Advanced Magnetic Technologies

Sapphire’s FreeSpin In-line Turboexpander (FIT) system includes advanced active magnetic bearings (AMBs), a high-speed permanent magnet (PM) generator and a high-frequency variable-speed drive (VSD). As shown in Fig. 1, high-pressure gas flows into the FIT and expands through a radial turbine wheel. The gas’ kinetic energy drives the wheel to rotate, which spins a directly coupled PM generator. Current produced by the generator is transferred to the VSD, where frequency and voltage are regulated to match the local grid. After expanding through the wheel and passing through the FIT housing, the gas exits the FIT at a pressure and temperature required by distribution regulations.

During operation, the AMBs levitate the coupled shaft, minimising frictional wear and losses for the system’s rotating components. AMBs replace more traditional rolling-element or fluid-film bearings, and the failure-prone auxiliary lubrication systems needed to maintain them. This eliminates the risk of oil contamination in the city gas pipeline and reduces the footprint of new equipment installation.

The PM generator incorporates patented rotor topology and provides up to 98% electromagnetic (EM) efficiency. It requires no external cooling; instead, the cool expanded gas passing through the FIT housing provides integrated heat removal from the PM generator’s rotor and stator.

The VSD has a footprint of 4m2 and houses all required power electronics and AMB controls. It can condition current to the local electric standard, delivering 380-480VAC at 50-60Hz (three phase). The VSD is suitable for outdoor installation with NEMA 4X power electronics enclosures.

Enthalpy Versus Entropy

Enthalpy is related to the heat content or the internal energy of a system. Entropy is related to a system’s ability to do work. J-T valves and TEGs affect the enthalpy and entropy of natural gas in different ways.

J-T valves are constant enthalpy devices and TEGs are constant entropy devices. This begins to explain why pressure energy is “wasted” in J-T valves. Since a J-T valve is a constant enthalpy device, the internal energy of the gas upstream and downstream of the valve must be the same. In a TEG, the values may differ, and the difference represents the work done on the turbine wheel to drive the PM generator. In other words, the conversion of waste-pressure energy into electric power is accomplished by extracting enthalpy from natural gas in

the pipeline.

Consider a city gas distribution process in which a pipeline delivers natural gas to a pressure reduction station at 35bar-g and 30°C. The gas must be reduced to a pressure of 25bar-g before it enters the city gas distribution network. The operator may use a J-T valve to meet the distribution regulation. In doing so, the gas will be expanded isentropically, or with constant enthalpy (h), as shown in Fig. 2.

Alternatively, the gas may be expanded isentropically, or with constant entropy(s), in a TEG. This process is described by Fig. 3. In doing so, it is observed that the specific enthalpy of the expanded gas (at 25bar-g) is lower than the specific enthalpy of the high-pressure gas (at 35bar-g). The difference in these specific enthalpies may be multiplied by the natural gas mass flow to calculate the amount of power available to spin the PM generator. For this process, the isentropic power is 515kW.

Multiple Applications

In addition to city gas distribution, TEGs such as the FIT can be used to recover natural gas waste-pressure energy in the upstream (wellheads), midstream (fuel gas for engines and turbines, gas processing plants), and downstream (refinery) industries. The use of J-T valves is common in oil and gas operations, and each segment of the supply chain has many applications where TEGs can be installed to convert waste-pressure energy into electricity.

The target market for TEGs is broader than one process gas. For instance, Sapphire is closely monitoring developments in the hydrogen economy, where FIT enables many of the same waste-pressure energy recovery applications listed above. Hydrogen usage is expected to grow over the next 10 years, but high costs of production, transportation and storage remain prohibitive, delaying the gas’ widespread adoption as an energy source. By recovering waste-pressure energy throughout new hydrogen infrastructure, TEGs can improve project financials and accelerate the adoption of this energy source.

Environmental, Social And Corporate Governance (ESG)

With ESG initiatives requiring more conscious operations, waste-pressure energy recovery projects represent low-hanging fruit for natural gas distributors. Consider the same city gas distribution process and assume that the operator flows 50 million standard cubic feet per day (MMSCFD) through a TEG such as the FIT. Sapphire’s FIT system is estimated to produce 410kW of power with an isentropic efficiency of 85%. During continuous operation, FIT will generate 3,595MWh per year and offset 2,555 tonnes of CO2 equivalent emissions.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.