In a final step, the response of the housing in a stage railway gearbox is studied. In a prior step in the project, the original gear macro- and microgeometry was optimized. A forced response analysis was conducted using the gear mesh force variation during the meshing cycle as excitation. The housing response was calculated for both the original and optimized gear macro and micro geometry and the gearbox equivalent radiated power as an indicator for airborne noise was compared. No waviness was applied to the gears. Using the same methodology and tools, the gear mesh force variation was calculated using the optimized gear, once without waviness, once with waviness applied. For this, the LTCA as implemented in KISSsoft was used. For the gear without waviness, the gear mesh force variation was 2,110 N, whereas for the gear having waviness, it was 2,500 N (rounded to 10 N each).

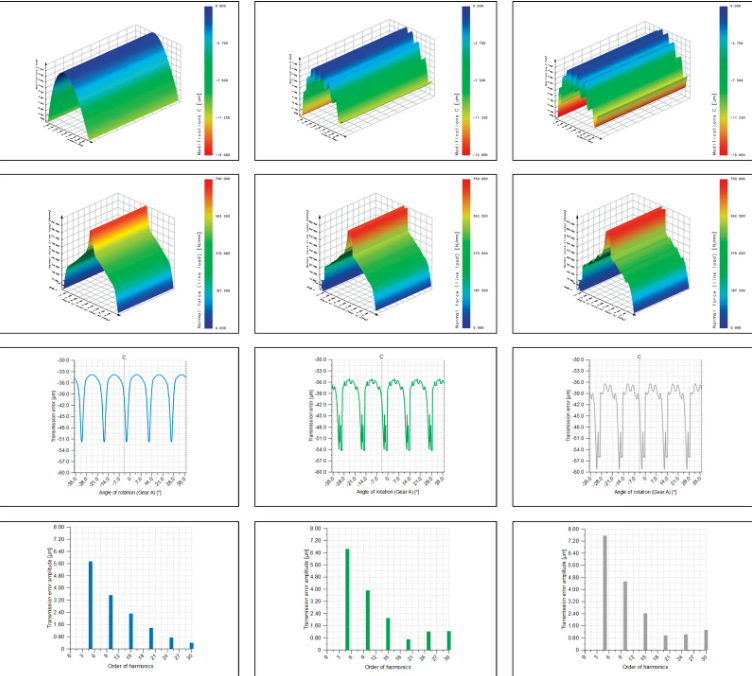

Left column: results without waviness. Middle column: results with waviness, amplitude = reference amplitude. Right column: results with waviness, amplitude = 2 x reference amplitude. First row: Profile modification, superimposition of profile crowning plus waviness. Second row: Contact force over mesh. Third row: Transmission error. Fourth row: Amplitude spectrum of transmission error.

The variation in gear mesh force, calculated in the forced response analysis in KISSsoft, resulted in variation of bearing forces as shown on the left side of Figure 15. The bearing forces (in the time domain) are exported from KISSsoft and imported into RecurDyn, where the housing is subjected to dynamic analysis. On the housing, several virtual accelerometers are placed at critical locations and displacement, velocity and acceleration in the nodes where these virtual accelerometers are placed are recorded in the time domain. Converting the time domain results by Fourier transformation into a frequency domain result allows for plotting of the e.g., velocity vs. frequency. On the left side of Figure 16, the velocity of the node where the virtual accelerometer is placed is shown for the gear without waviness applied. We see a few peaks at low frequencies and then a peak at the gear mesh frequency of 825Hz. We see the same peak, but at a higher amplitude, for the gear with waviness applied on the right side of Figure 16. The velocity increases from 3.58 m/s to 4.75 m/s, an increase of 33 percent. With this, we may conclude that the process, methods and tools are likely to be suitable for the assessment and optimization of waviness aiming at a reduced gearbox noise level. Obviously, further work to deepen the understanding of the approach and results is needed. Also, this approach is not automatized and requires experience and engineering judgement for the assessment of results. It is currently suitable for specific projects or troubleshooting, but not for use in quality control of thousands of gears. In sound critical applications where a few units of gears are used, e.g., marine gearboxes, the above process looks promising. It also looks promising for critical applications where many units with consistent manufacturing are manufactured, e.g., for aerospace or EV gearboxes.

Next Gear Mesh Example

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.