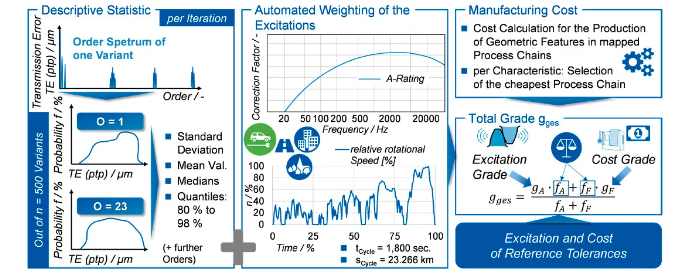

The evaluation of a tolerance design is carried out for the acoustics in the form of a score, which is determined for the various excitation orders in accordance with the section “Evaluation of the Design of the Excitation Behavior.” A price is determined as a fictitious currency (fC) for the production costs. This is set in relation to the fictitious price of the reference design. The result is an overall score according to the formula in Figure 6 on the right.

Manufacturing costs for the geometry features reduced by p = -25 percent compared to the reference mean the grade gF = 1, costs increased by p = +25 percent set the cost grade for manufacturing linear to gF = 6. In this case, the individual grades gA and gF are multiplied by freely selectable weighting factors fA and fF. The overall grade gges assumes values less than gges < 3.5 if both the manufacturing costs as determined in the section “Modeling the Cost-Deviation Relationships for Geometric Features” and the excitation behavior are lower than the reference case. The procedure for determining the excitation grade gA in accordance with the procedure in the section “Evaluation of the Design of the Excitation Behavior” is also shown in Figure 6 on the left and in the middle. Optimization Problem and Solution Approaches The evaluation of acoustic behavior and production costs results in a design dilemma in which costs and noise excitation are contradictory. From this, a multi-criteria optimization problem can be derived, for which there are solution methods. While the goal of a conventional Particle-Swarm Algorithm is to minimize a single output variable (here: total score gges) with a certain combination of input variables (here: quality classes of different deviation types), an ideal combination of input variables can be determined iteratively with a Pareto Optimization. The enveloping curve over all combinations of input variables that lead to the best fulfillment of the different objectives is referred to as the Pareto front (Ref. 38). Advanced algorithms combine the approaches of genetic particle swarm optimization with multi-objective optimization. One example of this is the metaheuristic MOPSO (Multi-Objective Particle Swarm Optimization) method (Ref. 26). In this approach, the swarm population is used to determine the Pareto front in a time-efficient manner. The weighting between excitation quality and production effort as an overall score is omitted in advance. Instead of an ideal solution, this results in a set of solutions that differ in terms of their degree of fulfillment of the subline. The properties of the variants on the Pareto-Front can then be compared using the weighting function and the best individual compromise solution can be selected.

Next Correlations for Manufacture-Related Geometric Deviations and Resulting Costs

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.