New FAG Bearing Concept With Axial Splines

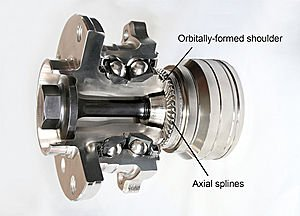

A reduction in weight of around ten percent and a significantly simplified mounting procedure compared with conventional radial splines - these are the most important advantages of the new FAG wheel bearing concept that is preloaded by means of axial splines in the axle journal. The use of the orbitally formed shoulder as a carrier for a clearance-free axial gear teeth enables this wheel bearing module to be produced very economically.

Low weight, economical to fit

Normally, the drive torque is transmitted between the wheel bearing and the axle journal by means of radial splines. The teeth usually have a certain amount of clearance in order to make mounting easier.

Loads that occur in day-to-day driving conditions mean that there is a risk that the assembly constantly loosens way beyond the normal mounting clearance, resulting in everything from losses in comfort and uncomfortable noises right up to the failure of the bearing. Up to now, the only solution was to reduce the radial clearance to zero in the design phase, which necessitates the use of expensive and complex mounting technology.

However, the new FAG wheel bearing module with axial splines is appealing due to simple mounting methods. The self-centering axial gear teeth are placed on the axle journal and fixed in placed by means of the central screw in the assembly. The bearing remains completely clearance-free in the gear teeth during operation. Regardless of whether the vehicle travels 1,000 or 100,000 kilometers, the bearing won’t budge during the entire operating life!

Another piece of good news is the fact that the system weighs around ten percent less than a conventional bearing. On four wheels in a vehicle, this involves a weight saving of over one kilogram.

The orbitally-formed shoulder makes everything possible

The idea behind axial splines is not new, however, the economical production of this design idea first became a reality when an orbitally-formed shoulder was used as a carrier for the gear teeth. In 1989, initially for wheel bearings in the Seat Marbella and later in BMW’s mid-class sedans, FAG axially fixed the bearing inner ring with the orbitally formed shoulder thereby eliminating the screw fixing that was common at that time. In the new wheel bearing concept, the axial splines are applied onto the orbitally-formed shoulder by high-precision cold forming. A comprehensive series of tests has shown that the torque transmission with the axial splines is considerably higher compared with radial splines, mainly due to the larger diameter of the pitch circle of the gear teeth.

Schaeffler KG engineers have been working on this new design idea since 2004 and the start of volume production for all-wheel drive sedans in the mid and upper-classes has already been scheduled for next year. The advantages in terms of cost-effectiveness and environmental aspects have already been recognized. More and more spur gear teeth will replace the conventional radial gear teeth in other vehicle classes.

A reduction in weight of around ten percent and a significantly simplified mounting procedure compared with conventional radial splines - these are the most important advantages of the new FAG wheel bearing concept that is preloaded by means of axial splines in the axle journal. The use of the orbitally formed shoulder as a carrier for a clearance-free axial gear teeth enables this wheel bearing module to be produced very economically.

Low weight, economical to fit

Normally, the drive torque is transmitted between the wheel bearing and the axle journal by means of radial splines. The teeth usually have a certain amount of clearance in order to make mounting easier.

Loads that occur in day-to-day driving conditions mean that there is a risk that the assembly constantly loosens way beyond the normal mounting clearance, resulting in everything from losses in comfort and uncomfortable noises right up to the failure of the bearing. Up to now, the only solution was to reduce the radial clearance to zero in the design phase, which necessitates the use of expensive and complex mounting technology.

However, the new FAG wheel bearing module with axial splines is appealing due to simple mounting methods. The self-centering axial gear teeth are placed on the axle journal and fixed in placed by means of the central screw in the assembly. The bearing remains completely clearance-free in the gear teeth during operation. Regardless of whether the vehicle travels 1,000 or 100,000 kilometers, the bearing won’t budge during the entire operating life!

Another piece of good news is the fact that the system weighs around ten percent less than a conventional bearing. On four wheels in a vehicle, this involves a weight saving of over one kilogram.

The orbitally-formed shoulder makes everything possible

The idea behind axial splines is not new, however, the economical production of this design idea first became a reality when an orbitally-formed shoulder was used as a carrier for the gear teeth. In 1989, initially for wheel bearings in the Seat Marbella and later in BMW’s mid-class sedans, FAG axially fixed the bearing inner ring with the orbitally formed shoulder thereby eliminating the screw fixing that was common at that time. In the new wheel bearing concept, the axial splines are applied onto the orbitally-formed shoulder by high-precision cold forming. A comprehensive series of tests has shown that the torque transmission with the axial splines is considerably higher compared with radial splines, mainly due to the larger diameter of the pitch circle of the gear teeth.

Schaeffler KG engineers have been working on this new design idea since 2004 and the start of volume production for all-wheel drive sedans in the mid and upper-classes has already been scheduled for next year. The advantages in terms of cost-effectiveness and environmental aspects have already been recognized. More and more spur gear teeth will replace the conventional radial gear teeth in other vehicle classes.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next MRC Hybrid Ceramic Ball Bearings Offered In Extra-Large Bore Sizes

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.