Development of “Low Torque Roller Lifter Unit” for Engine Fuel Pump

Resource from: Low Torque Roller Lifter Unit Likes:3100

May 21,2010

NTN Corporation (hereafter NTN) has developed a “Low torque roller lifter unit” for fuel pump drive systems of automotive direct injection engines.

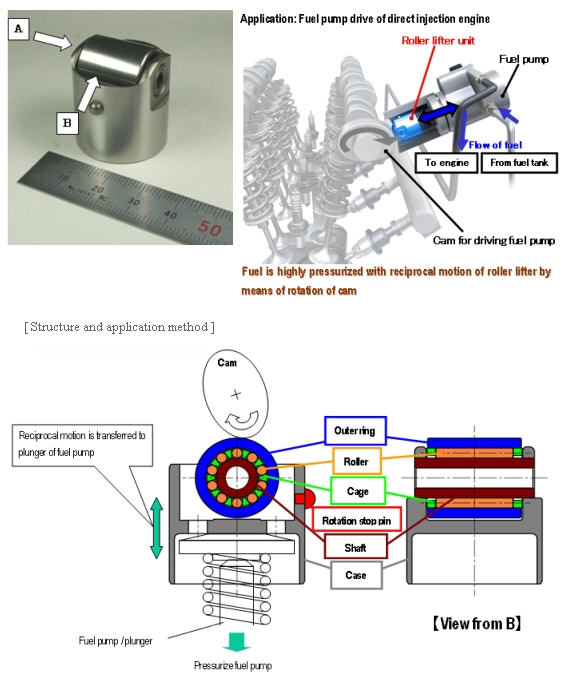

Unlike a normal aspirated engine where air/fuel mixture enters the cylinder, feature of the direct injection engine is that only air is suctioned into cylinders and compressed while fuel highly pressurized by a fuel pump is directly injected into the cylinders. The Roller lifter unit (hereafter “Lifter”) ensures smoother movement in the fuel pump drive system of direct injection engines by means of rotation of a roller between the cam and plunger.

Conventional lifter types (sliding contact with cam) have been mainstream, but use of roller bearings (full complement type) in place of a roller to reduce fiction loss is being increasingly used by automotive manufactures. However, with the roller full complement type bearing, some issues such as heat generation or increase of rotational torque due to contact of roller to roller exists.

NTN developed a lightweight roller lifter by using a with-cage specification to prevent the contact of roller-to-roller, and achieved high-speed performance corresponding to a rotational speed of 36,000min-1 as well as up to a 30% reduction in rotational torque compared with a full complement roller type lifter. The weight reduction (10%) while ensuring the necessary strength for the lifter was attained by making full use of the NTN's own long life technology (FA heat treatment*1) and FEM*2 analysis technology.

NTN initiated sales activity to automotive/pump manufactures to contribute enhancement of engine fuel pump efficiency.

*1) Fine Austenite Strengthening: Complex heat treatment technology combining the crystal grain miniaturization of bearing steel and the carburizing/nitriding treatment

*2) Finite Element Method

[ Features ]

(1)Low friction: Bearing rotational torque reduced up to 30% (compared with conventional product)

(2)High speed: Corresponding to bearing rotational speeds of 36,000min-1

(Bearing pitch circle diameter: with 10mm bore diameter, 18,000min-1 or less in roller full complement type)

(3)Light weight: Weight reduction of 10% (compared with the conventional product)

[ Application ]

Fuel pump drive system of automotive direct injection engine

[ Contact ]

Planning Department, Automotive Business H.Q. Tel. 03-5487-2820

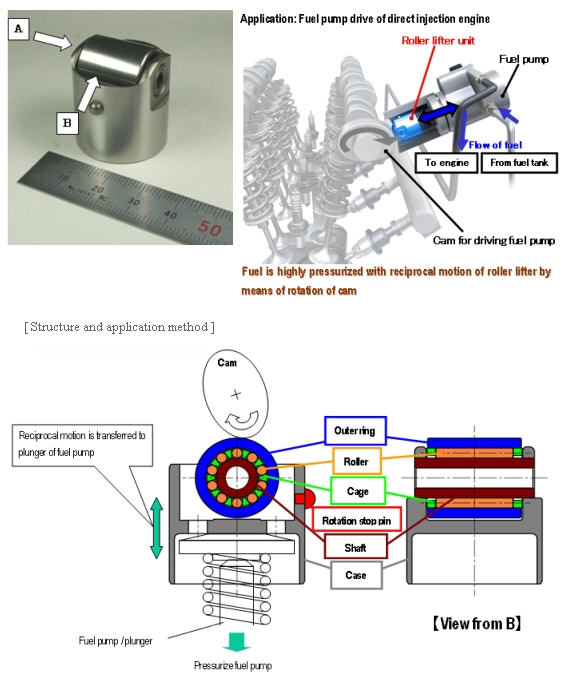

[ Product photo ] [ Applied position−Ex. Structure of high-pressure fuel pump ]

(Low Torque Roller Lifter Unit)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.