NTN Integrated Rotation Sensor Bearings

NTN Corporation (hereafter, NTN) had previously commercialized the “Integrated Rotation Sensor Bearings”*1 and has been selling them around the world, however in an industry first, has developed the “Integrated Rotation Sensor Large Size Bearing” capable of detecting the rotation speed of large bearings (up to 420 mm outer diameter).

Until now, large bearings and rotation sensors had been mounted separately within machinery. The positioning of components required for accurately detecting rotation speed also required delicate adjustment during the equipment assembly stage.

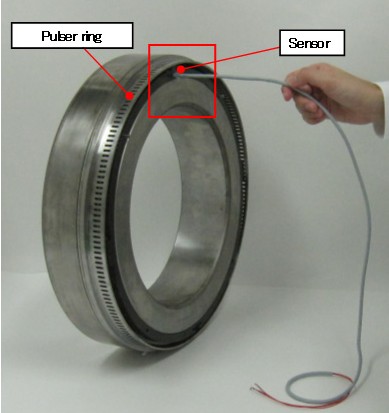

NTN has installed a pulse detection sensor within the still inner ring, and a pulser ring within the rotating outer ring, for applications that use large bearings with a rotating outer ring. Integrating the rotation sensor and bearing eliminates the need for adjustment and positioning during the assembly stage, reduces the number of components required, and results in a more compact bearing size.

The use of a sensor wiring layout mechanism that prevents disconnections allows detection of rotation speed without any damage or errors, even if the shaft and bearing inner ring start to creep (a form of differential rolling). The system can also be used when immersed in oil and under vibrating conditions.

NTN plans to deliver the new bearing to various industrial machinery that requires detection of rotation speed of large bearings, including applications in the construction machinery, iron and steel facilities and wind power generators.

Features:

(1) Integrated rotation sensor and bearing

→ Reduces man-hours required for rotation sensor assembly, reduces the number of components and achieves a more compact housing size.

(2) Use of a sensor wiring layout mechanism that prevents disconnections, even if the shaft and bearing inner ring start to creep (a form of differential rolling)

→ Detection of rotation speed even if the inner ring starts to creep.

(3) Can be used when immersed in oil

→ Capable of accurately detecting rotation speed when mounted within engine oil (oil temperature 120°C × 2000 hours).

(may be affected by the type of oil or additives)

(4) Can be used under vibrating conditions

→ Capable of accurately detecting rotation speed under vibrational acceleration of 10G.

Applicable Bearing Sizes:

Can be used for large bearings up to 420 mm outer diameter.

NTN Corporation (hereafter, NTN) had previously commercialized the “Integrated Rotation Sensor Bearings”*1 and has been selling them around the world, however in an industry first, has developed the “Integrated Rotation Sensor Large Size Bearing” capable of detecting the rotation speed of large bearings (up to 420 mm outer diameter).

Until now, large bearings and rotation sensors had been mounted separately within machinery. The positioning of components required for accurately detecting rotation speed also required delicate adjustment during the equipment assembly stage.

NTN has installed a pulse detection sensor within the still inner ring, and a pulser ring within the rotating outer ring, for applications that use large bearings with a rotating outer ring. Integrating the rotation sensor and bearing eliminates the need for adjustment and positioning during the assembly stage, reduces the number of components required, and results in a more compact bearing size.

The use of a sensor wiring layout mechanism that prevents disconnections allows detection of rotation speed without any damage or errors, even if the shaft and bearing inner ring start to creep (a form of differential rolling). The system can also be used when immersed in oil and under vibrating conditions.

NTN plans to deliver the new bearing to various industrial machinery that requires detection of rotation speed of large bearings, including applications in the construction machinery, iron and steel facilities and wind power generators.

Features:

(1) Integrated rotation sensor and bearing

→ Reduces man-hours required for rotation sensor assembly, reduces the number of components and achieves a more compact housing size.

(2) Use of a sensor wiring layout mechanism that prevents disconnections, even if the shaft and bearing inner ring start to creep (a form of differential rolling)

→ Detection of rotation speed even if the inner ring starts to creep.

(3) Can be used when immersed in oil

→ Capable of accurately detecting rotation speed when mounted within engine oil (oil temperature 120°C × 2000 hours).

(may be affected by the type of oil or additives)

(4) Can be used under vibrating conditions

→ Capable of accurately detecting rotation speed under vibrational acceleration of 10G.

Applicable Bearing Sizes:

Can be used for large bearings up to 420 mm outer diameter.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next NSK HST Long-life, High-reliability Cage-equipped Thrust Ball Bearing for Agricultural Machinery

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.