NSK Energy-saving Bearings for High-efficiency Motors

Tokyo, Japan, September 28, 2011 - NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed energy-saving bearings for high-efficiency motors that halve the friction loss of rolling bearings used in conventional products. The new bearings will contribute to a reduction of electric power consumption desired by users of high-efficiency motors. NSK is aiming for annual sales of the new product of 7 billion yen by 2016.

Development background

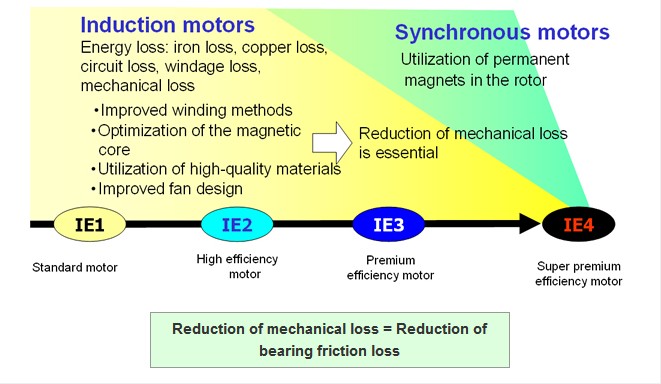

Reducing CO2 emissions and saving energy have become increasingly important in recent years as global warming countermeasures. Because motors account for 75% of industrial power consumption, efficiency regulations for motors are in place around the world. In 2008, the International Electrotechnical Commission (IEC) created global standards for motor efficiency. Nearly 90% of motor efficiency issues are caused by iron loss, copper loss, circuit loss, and windage loss, whereas mechanical loss related to bearing friction accounts for only about 10%. In coming years, as the efficiency level for motors progresses to IE3* and IE4*, the demand for bearings with low friction loss will increase.

* IE3、IE4: Efficiency levels set by the IEC. IE1 (standard efficiency), IE2 (high efficiency), IE3 (premium efficiency), IE4 (super premium efficiency).

Product features:

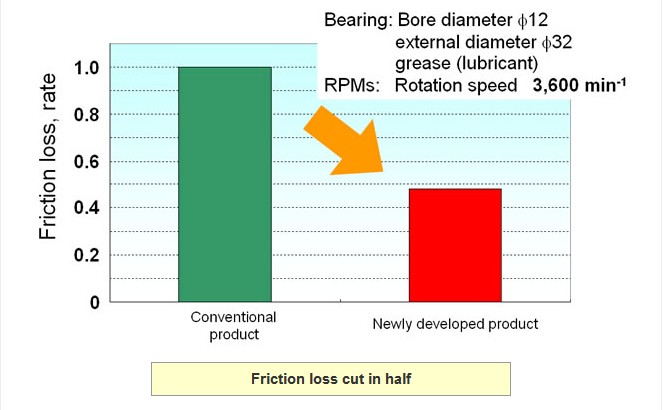

Extremely low friction loss: half the friction loss of conventional products

Optimization of bearing design has made it possible to reduce friction loss by half.

Product benefits

1. Contributes to increased efficiency and better energy-savings for motors

Conforms not only to JIS motor efficiency standards but also to the extremely demanding IE3 and IE4 efficiency standards of the IEC. This makes it possible to reduce the power consumption of industrial motors.

2. Increased reliability

Reduced bearing friction loss means bearings operate at lower temperatures, which increases the reliability of motors and other devices.

Development Background:

Motor trend toward more efficiency

Tokyo, Japan, September 28, 2011 - NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed energy-saving bearings for high-efficiency motors that halve the friction loss of rolling bearings used in conventional products. The new bearings will contribute to a reduction of electric power consumption desired by users of high-efficiency motors. NSK is aiming for annual sales of the new product of 7 billion yen by 2016.

Development background

Reducing CO2 emissions and saving energy have become increasingly important in recent years as global warming countermeasures. Because motors account for 75% of industrial power consumption, efficiency regulations for motors are in place around the world. In 2008, the International Electrotechnical Commission (IEC) created global standards for motor efficiency. Nearly 90% of motor efficiency issues are caused by iron loss, copper loss, circuit loss, and windage loss, whereas mechanical loss related to bearing friction accounts for only about 10%. In coming years, as the efficiency level for motors progresses to IE3* and IE4*, the demand for bearings with low friction loss will increase.

* IE3、IE4: Efficiency levels set by the IEC. IE1 (standard efficiency), IE2 (high efficiency), IE3 (premium efficiency), IE4 (super premium efficiency).

Product features:

Extremely low friction loss: half the friction loss of conventional products

Optimization of bearing design has made it possible to reduce friction loss by half.

Product benefits

1. Contributes to increased efficiency and better energy-savings for motors

Conforms not only to JIS motor efficiency standards but also to the extremely demanding IE3 and IE4 efficiency standards of the IEC. This makes it possible to reduce the power consumption of industrial motors.

2. Increased reliability

Reduced bearing friction loss means bearings operate at lower temperatures, which increases the reliability of motors and other devices.

Development Background:

Motor trend toward more efficiency

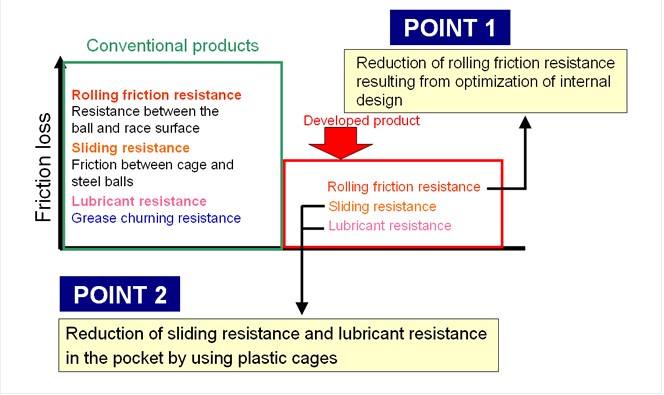

Development Concept:

In order to reduce bearing friction loss ...

Development Concept:

In order to reduce bearing friction loss ...

Reduction of Friction Loss: Friction Loss Data for Developed Product

Reduction of Friction Loss: Friction Loss Data for Developed Product

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Kilian Ball Bearing Housed Units for Tough Washdown Conditions in Food Processing and Packaging Operations

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.