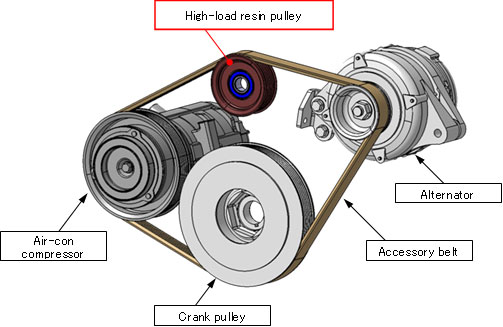

NTN High-load Resin Pulley for Engine Ancillary Belts

NTN Corporation (hereafter, NTN) has developed the “High-load Resin Pulley” used for engine accessory belt drive systems. These pulleys deliver the highest load resistance in the industry.

With increasing demand for better fuel economy and weight savings in cars, there has been a greater move to replace various steel parts throughout cars with plastic parts. Engine accessory belt pulleys are available in plastic to replace older steel pulleys in line with these moves. Yet the higher power output and rotational speed of engines due to the greater efficiency of engines has often resulted in slip (also known as creep) between the outer ring of the bearing and plastic parts, in addition the deformation of the pulley causes the mating between the outer ring of the bearing and seal to become loose and grease to leak out as the seal rotates.

The “High-load Resin Pulley” developed by NTN uses high-rigidity plastic able to withstand the high temperatures around the engine. It also employs an optimum creep prevention groove on the outer surface of the bearing, and improvements to the outer ring seal groove and seal outer surface shape to prevent pulley deformation. These changes serve to prevent creep and leaking grease under high power output or rotational speeds, while also providing more than sufficient durability and the highest load capacity in the industry, at more than double that of existing plastic pulleys. This allows steel pulleys to be replaced with developed products, resulting in weight savings of approximately 1/3 the original weight.

NTN plans to market and sell the “High-load Resin Pulley” globally as part of efforts to save weight of various car parts, while also contributing to better fuel economy and lower CO2 emissions of cars.

[Features]

Direct replacement of steel pulleys, and lighter weight

(1) More than double the high-load resistance of existing plastic pulleys (industry highest)

· Use of high-rigidity plastic

· Optimal creep prevention groove on outer surface of outer ring

· High-rigidity design for the outer ring seal groove and seal

(2) Lighter weight than steel pulleys (weight comparison: approximately 1/3)

[Applications]

Pulleys for car engine accessory belts

[Area of application]

Accessory belt drive system

NTN Corporation (hereafter, NTN) has developed the “High-load Resin Pulley” used for engine accessory belt drive systems. These pulleys deliver the highest load resistance in the industry.

With increasing demand for better fuel economy and weight savings in cars, there has been a greater move to replace various steel parts throughout cars with plastic parts. Engine accessory belt pulleys are available in plastic to replace older steel pulleys in line with these moves. Yet the higher power output and rotational speed of engines due to the greater efficiency of engines has often resulted in slip (also known as creep) between the outer ring of the bearing and plastic parts, in addition the deformation of the pulley causes the mating between the outer ring of the bearing and seal to become loose and grease to leak out as the seal rotates.

The “High-load Resin Pulley” developed by NTN uses high-rigidity plastic able to withstand the high temperatures around the engine. It also employs an optimum creep prevention groove on the outer surface of the bearing, and improvements to the outer ring seal groove and seal outer surface shape to prevent pulley deformation. These changes serve to prevent creep and leaking grease under high power output or rotational speeds, while also providing more than sufficient durability and the highest load capacity in the industry, at more than double that of existing plastic pulleys. This allows steel pulleys to be replaced with developed products, resulting in weight savings of approximately 1/3 the original weight.

NTN plans to market and sell the “High-load Resin Pulley” globally as part of efforts to save weight of various car parts, while also contributing to better fuel economy and lower CO2 emissions of cars.

[Features]

Direct replacement of steel pulleys, and lighter weight

(1) More than double the high-load resistance of existing plastic pulleys (industry highest)

· Use of high-rigidity plastic

· Optimal creep prevention groove on outer surface of outer ring

· High-rigidity design for the outer ring seal groove and seal

(2) Lighter weight than steel pulleys (weight comparison: approximately 1/3)

[Applications]

Pulleys for car engine accessory belts

[Area of application]

Accessory belt drive system

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next NTN Filter Seal Integrated Large Size Bearing

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.