NTN Launched "Self-formed Seal Low Torque Deep Groove Ball Bearing" for Transmissions (fig)

Resource from: NTN Corporation Likes:3159

May 14,2012

[Non-contact seals capable of reducing rotational torque by 80% by self-forming minute gaps]

NTN Corporation (hereafter, NTN) has developed the “Self-formed Seal Low Torque Deep Groove Ball Bearing” for transmissions that is capable of reducing rotational torque by up to 80%*1 to help improve fuel efficiency and reduce CO2 emissions of automobiles.

To prevent a reduction in operating life of bearings for automotive transmissions due to the penetration of foreign objects, sealed ball bearings with contact seals are often used. Yet rotational torque is often larger than ball bearings without seals, and these bearings are often plagued with issues related to degradation due to poor lubrication.

The new “Self-formed Seal Low Torque Deep Groove Ball Bearing” employs a newly developed seal that self-forms minute gaps between the inner ring and seal. The end of the seal that comes in contact with the inner ring is a non-contact type seal that cannot be manufactured using machining or molding processes, as these seals form minute gaps during the initial stages of bearing operation. The rubber composition of the seal has been improved, and the type of contact between end of the seal and the inner ring has been changed from the conventional axial contact structure*2 to the radial contact structure*3 to ensure more reliable minute gaps are formed during the initial stages of bearing operation. These designs prevent penetration of foreign objects into the bearing that reduce its operating life, while also reducing rotational torque by up to 80% and supplying ample lubrication throughout the bearing with up to five-times the lubrication flow compared to conventional contact type bearings.

NTN will be exhibiting the newly developed product at the “Automotive Engineering Exposition 2012” to be held at Pacifico Yokohama between May 23 and 25, and plans to market the product globally as a product to help improve fuel efficiency and reduce CO2 emissions of automobiles.

*1: Compared to the conventional “Light Contact Seal Ball Bearing”.

*2: Bearing structure where the sliding sections of seal ends are in contact with the bearing inner ring in an axial direction.

*3: Bearing structure where the sliding sections of seal ends are in contact with the bearing inner ring in a radial direction.

[ Features ] Effects of self-formed seals: compared to conventional products

(1) Rotational torque : up to 80% reduction

(2) Operating life : same or better operating life under lubrication conditions with penetration of foreign objects

(same level of foreign object penetration prevention as light contact seals)

(3) Lubrication : five-times the lubrication flow (improved anti-seizing)

[ Inquiries about this release ]

Business Planning Department, Automotive Business Headquarters

TEL: +81-538-37-8418

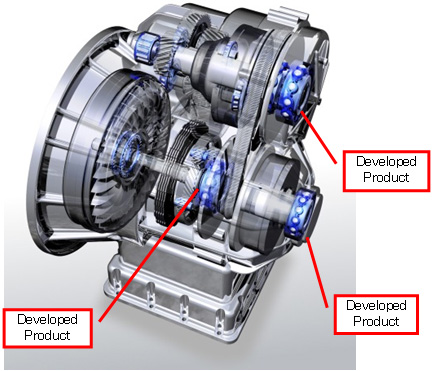

[ Product Photo ]

“Self-formed Seal Low Torque Deep Groove Ball Bearing”

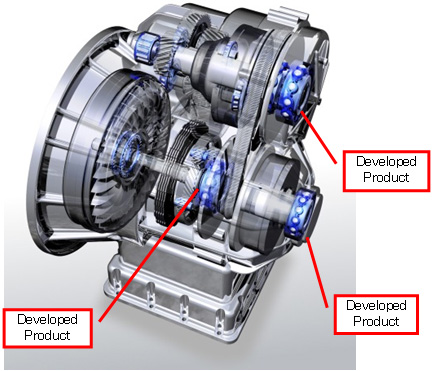

[ Applicable Parts ]

“Self-formed Seal Low Torque Deep Groove Ball Bearing”

[ Applicable Parts ]

Applicable parts of transmissions (CVT) and the developed product (example)

Applicable parts of transmissions (CVT) and the developed product (example)

(NTN Corporation)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

“Self-formed Seal Low Torque Deep Groove Ball Bearing”

[ Applicable Parts ]

“Self-formed Seal Low Torque Deep Groove Ball Bearing”

[ Applicable Parts ]

Applicable parts of transmissions (CVT) and the developed product (example)

Applicable parts of transmissions (CVT) and the developed product (example)