NSK Develops the World's First Low Torque Rolling Bearing for High Efficiency Centrifugal Chillers Used in Large Facilities for Air Conditioning Equipment Applications

*1: According to NSK's findings as of March 2012

Development background

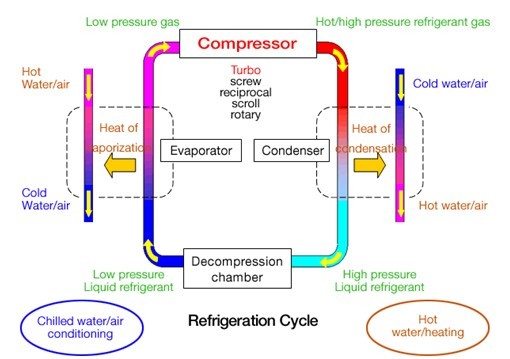

Reducing CO2 emissions and saving energy have become increasingly important in recent years as global warming countermeasures. In an effort to preserve the environment, the demand for centrifugal chillers, which have a high level of energy efficiency, has risen for air conditioner systems in large-scale facilities because such systems consume a great deal of power and fuel. Generally speaking, centrifugal chillers consist of a motor-driven centrifugal compressor that rotates an impeller to cause the refrigerant to blow outwards, and then the compressor compresses to circulate the refrigeration cycle. In terms of refrigeration capacity (cooling capacity), these machines typically range from 100 to 10,000 refrigeration tons*2. That alone is a lot of load to handle, but on top of that, in recent years there has been a push for even higher efficiency and compactness, which has resulted in the compressors of these centrifugal chillers getting faster and faster. Of course, this is resulting in extremely demanding conditions for the bearings both in terms of speed and load, which in turn demands a high level of bearing technology.

NSK has responded to this demand by leveraging the experience it has built in aircraft applications to create a bearing that is highly reliable in environments 1.5 times faster than sliding bearings, and cuts friction loss in half through the use of such technology as high speed orientated cage shapes and lubrication methods.

Refrigeration Cycle

*1: According to NSK's findings as of March 2012

Development background

Reducing CO2 emissions and saving energy have become increasingly important in recent years as global warming countermeasures. In an effort to preserve the environment, the demand for centrifugal chillers, which have a high level of energy efficiency, has risen for air conditioner systems in large-scale facilities because such systems consume a great deal of power and fuel. Generally speaking, centrifugal chillers consist of a motor-driven centrifugal compressor that rotates an impeller to cause the refrigerant to blow outwards, and then the compressor compresses to circulate the refrigeration cycle. In terms of refrigeration capacity (cooling capacity), these machines typically range from 100 to 10,000 refrigeration tons*2. That alone is a lot of load to handle, but on top of that, in recent years there has been a push for even higher efficiency and compactness, which has resulted in the compressors of these centrifugal chillers getting faster and faster. Of course, this is resulting in extremely demanding conditions for the bearings both in terms of speed and load, which in turn demands a high level of bearing technology.

NSK has responded to this demand by leveraging the experience it has built in aircraft applications to create a bearing that is highly reliable in environments 1.5 times faster than sliding bearings, and cuts friction loss in half through the use of such technology as high speed orientated cage shapes and lubrication methods.

Refrigeration Cycle

*2: One refrigeration ton is the cooling capacity required to phase change one ton of water at 0℃ to one ton of ice at 0℃.

Product features

1. Extremely low friction loss: half the friction loss of conventional products

By employing creative measures in the design of the bearing such as shape optimization of the cage and lubrication volume, this rolling bearing is able to cut friction loss to half of that of the widely used sliding bearings.

2. Improved durability through optimization of bearing interior specifications

The problem with typical rolling bearings under high-speed conditions is that the lubrication oil within the bearing gets agitated, resulting in friction loss in the bearing, which in turn leads to a variety of problems such as seizure and shortened life. This product is optimized in terms of the cage shape, material combination (brass and resin) and lubrication methodology to improve oil scavenging and thereby prevent seizure and also achieve sufficient product life.

Product benefits

1. Helps save energy

In reducing bearing friction loss, this product helps improve the performance of the centrifugal chillers, resulting in a roughly 20% improvement in energy savings compared to conventional refrigeration machines.

2. Improved compaction of the refrigerant

Modifying the bearing to high-speed applications also improves the compaction of the refrigerant, which in turn helps the turbo refrigeration machine achieve a high level of efficiency and compactness.

3. Less maintenance frequency

In reducing bearing friction loss and improving the lubrication performance, the bearing temperature is kept from rising, thereby improving reliability of the equipment.

*2: One refrigeration ton is the cooling capacity required to phase change one ton of water at 0℃ to one ton of ice at 0℃.

Product features

1. Extremely low friction loss: half the friction loss of conventional products

By employing creative measures in the design of the bearing such as shape optimization of the cage and lubrication volume, this rolling bearing is able to cut friction loss to half of that of the widely used sliding bearings.

2. Improved durability through optimization of bearing interior specifications

The problem with typical rolling bearings under high-speed conditions is that the lubrication oil within the bearing gets agitated, resulting in friction loss in the bearing, which in turn leads to a variety of problems such as seizure and shortened life. This product is optimized in terms of the cage shape, material combination (brass and resin) and lubrication methodology to improve oil scavenging and thereby prevent seizure and also achieve sufficient product life.

Product benefits

1. Helps save energy

In reducing bearing friction loss, this product helps improve the performance of the centrifugal chillers, resulting in a roughly 20% improvement in energy savings compared to conventional refrigeration machines.

2. Improved compaction of the refrigerant

Modifying the bearing to high-speed applications also improves the compaction of the refrigerant, which in turn helps the turbo refrigeration machine achieve a high level of efficiency and compactness.

3. Less maintenance frequency

In reducing bearing friction loss and improving the lubrication performance, the bearing temperature is kept from rising, thereby improving reliability of the equipment.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next AutomationDirect Adds Proximity Sensors

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.