NSK Develops a Ball Screw with Minimal Grease Splatter

Reduced Grease Splatter for Cleaner Device and Working Environment

Tokyo, Japan, October 11, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a ball screw that minimizes grease splatter thanks to the new L1 seal, an original seal NSK is positioning as an industry-first which greatly reduces the amount of grease splattered by ball screws. NSK will launch this product in January 2014 and is targeting 500 million yen in sales in 2016.

NSK will be exhibiting this product from Wednesday, October 2, 2013 to Friday, October 4, 2013 at the 16th Mechanical Components & Materials Technology Expo Osaka being held at INTEX OSAKA.

Development Background

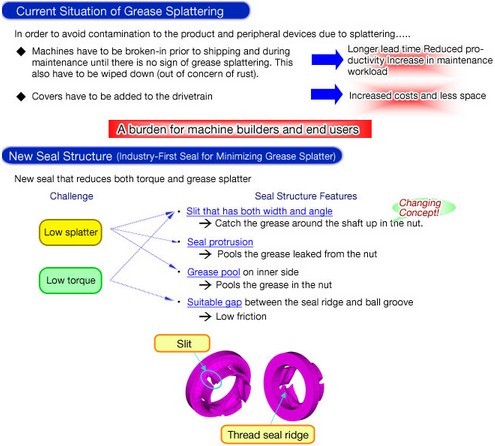

Electronic device mounting machines, semiconductor- and LCD-conveyance equipment, medical devices, and equipment for food products and related packaging are used in clean environments, and as such, require features that prevent grease from splattering. In recent years there has been an increase in grease splattering due to the increase in the rotation speed of ball screws driven by the demand for shorter production times.

In response to this, NSK has developed a ball screw that minimizes grease splatter thanks to an L1 seal, which reduces the amount of grease splattered without increasing friction loss.

Product Features

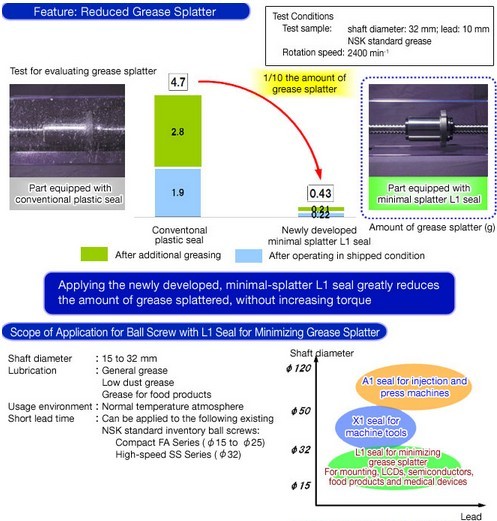

1. Dramatic reduction in grease splatter

The newly developed L1 seal is a non-contact seal that employs a structure that prevents grease from accumulating on the screw shaft surface, which in turn reduces the amount of grease splattered without increasing friction loss. This newly developed seal reduces the amount of grease splattered by ball screws to 1/10th that of NSK's previous product.

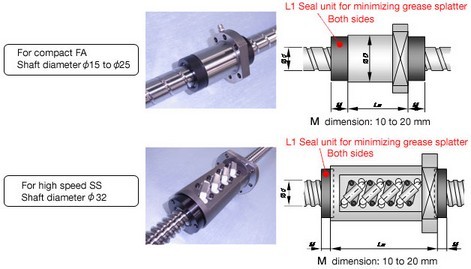

2. Standard seal cover

A cover designed to cover the outer circumference of the seal comes standard. This prevents grease that has pooled up in the circumference of the seal from dripping, delivering an even cleaner result.

3. Can be applied to existing standard inventory ball screws

Reduced Grease Splatter for Cleaner Device and Working Environment

Tokyo, Japan, October 11, 2013 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a ball screw that minimizes grease splatter thanks to the new L1 seal, an original seal NSK is positioning as an industry-first which greatly reduces the amount of grease splattered by ball screws. NSK will launch this product in January 2014 and is targeting 500 million yen in sales in 2016.

NSK will be exhibiting this product from Wednesday, October 2, 2013 to Friday, October 4, 2013 at the 16th Mechanical Components & Materials Technology Expo Osaka being held at INTEX OSAKA.

Development Background

Electronic device mounting machines, semiconductor- and LCD-conveyance equipment, medical devices, and equipment for food products and related packaging are used in clean environments, and as such, require features that prevent grease from splattering. In recent years there has been an increase in grease splattering due to the increase in the rotation speed of ball screws driven by the demand for shorter production times.

In response to this, NSK has developed a ball screw that minimizes grease splatter thanks to an L1 seal, which reduces the amount of grease splattered without increasing friction loss.

Product Features

1. Dramatic reduction in grease splatter

The newly developed L1 seal is a non-contact seal that employs a structure that prevents grease from accumulating on the screw shaft surface, which in turn reduces the amount of grease splattered without increasing friction loss. This newly developed seal reduces the amount of grease splattered by ball screws to 1/10th that of NSK's previous product.

2. Standard seal cover

A cover designed to cover the outer circumference of the seal comes standard. This prevents grease that has pooled up in the circumference of the seal from dripping, delivering an even cleaner result.

3. Can be applied to existing standard inventory ball screws

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.