Schaeffler: Quick and safe mounting for large-size bearings in wind power

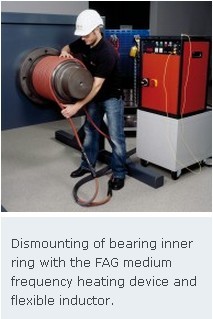

Medium frequency technology is the innovative solution from Schaeffler for induction heating of large and heavy parts. The induction is generated by medium frequency and enables to heat bearings in a short time in order to prepare them for mounting. Particularly in wind power, where standard methods meet their limits, this technology offers energy efficiency, safety, and a high degree of flexibility. The FAG medium frequency heating device is mobile and allows the heating of a wide variety of components, even in hard-to-reach locations. It is significantly lighter than standard mains frequency systems, and flexible inductors permit quick, safe, and controlled heating. As there are a number of versions and customized designs, the FAG medium frequency heating device is versatile and offers a reliable and economical solution, even for complex applications.

FAG medium frequency heating device for more flexibility

It is difficult to imagine that bearing inner rings with an external diameter of over three meters and a weight of several tons can be heated in much less than an hour and thus be ready for mounting. That is possible with the FAG medium frequency heating device. It consists of a generator and an inductor, which can have a flexible or fixed design depending on the application. The flexible version resembles a cable which can be placed either outside on the component or in the bore. The length of the flexible inductor depends on the application and can be up to 50 meters. Thus it has maximum adaptability to a variety of sizes and shapes. For volume produced applications, where the same components are mounted in large numbers, flexibility is less important than shortened setup times and process reliability. Fixed inductors are suitable here. In this version, the coil is built into a housing adapted to the component and thus can be placed in the heating zone quickly and easily.

Customer solutions with fixed inductors in volume production

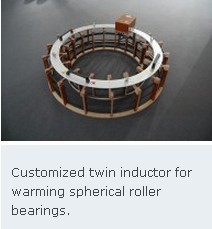

An order from a wind power customer required the heating of three FAG spherical roller bearings of the same type with bore diameters ranging from 800 to 1,050 millimeters. The customer was looking for a method to make its volume production faster, more efficient, and more reliable. Furthermore, homogeneous heating was necessary, because otherwise the bearings could have been damaged. Based on the parameters provided by the customer, such as geometric data, mounting location, process description, and power supply, Schaeffler’s experts determined the performance and functionality of the generator and the inductor design. They developed three different twin inductors in a fixed frame construction. The inductor coil was integrated into the frames so that the outer and inner rings would be heated at the same time. This ensured a homogeneous heating process, while at the same time reducing the time required by 50% and the energy costs by over 60%.

Medium frequency technology is the innovative solution from Schaeffler for induction heating of large and heavy parts. The induction is generated by medium frequency and enables to heat bearings in a short time in order to prepare them for mounting. Particularly in wind power, where standard methods meet their limits, this technology offers energy efficiency, safety, and a high degree of flexibility. The FAG medium frequency heating device is mobile and allows the heating of a wide variety of components, even in hard-to-reach locations. It is significantly lighter than standard mains frequency systems, and flexible inductors permit quick, safe, and controlled heating. As there are a number of versions and customized designs, the FAG medium frequency heating device is versatile and offers a reliable and economical solution, even for complex applications.

FAG medium frequency heating device for more flexibility

It is difficult to imagine that bearing inner rings with an external diameter of over three meters and a weight of several tons can be heated in much less than an hour and thus be ready for mounting. That is possible with the FAG medium frequency heating device. It consists of a generator and an inductor, which can have a flexible or fixed design depending on the application. The flexible version resembles a cable which can be placed either outside on the component or in the bore. The length of the flexible inductor depends on the application and can be up to 50 meters. Thus it has maximum adaptability to a variety of sizes and shapes. For volume produced applications, where the same components are mounted in large numbers, flexibility is less important than shortened setup times and process reliability. Fixed inductors are suitable here. In this version, the coil is built into a housing adapted to the component and thus can be placed in the heating zone quickly and easily.

Customer solutions with fixed inductors in volume production

An order from a wind power customer required the heating of three FAG spherical roller bearings of the same type with bore diameters ranging from 800 to 1,050 millimeters. The customer was looking for a method to make its volume production faster, more efficient, and more reliable. Furthermore, homogeneous heating was necessary, because otherwise the bearings could have been damaged. Based on the parameters provided by the customer, such as geometric data, mounting location, process description, and power supply, Schaeffler’s experts determined the performance and functionality of the generator and the inductor design. They developed three different twin inductors in a fixed frame construction. The inductor coil was integrated into the frames so that the outer and inner rings would be heated at the same time. This ensured a homogeneous heating process, while at the same time reducing the time required by 50% and the energy costs by over 60%.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next SKF Simplex-Compact Airspace seal is recognized as environmentally friendly in terms of VGP 2013

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.