NSK Expands Creep-Free™ Bearing Series Lineup

Tokyo, Japan, April 1, 2014 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has expanded its Creep-Free™ bearing series lineup. These bearings are widely used in fan and pump motors to prevent creep. This series of bearings is designed with exceptional creep resistance, which helps improve motor maintenance and assembly performance. NSK is targeting 1.2 billion yen in global annual sales by 2017 through this expansion to its Creep-Free™ bearing series lineup.

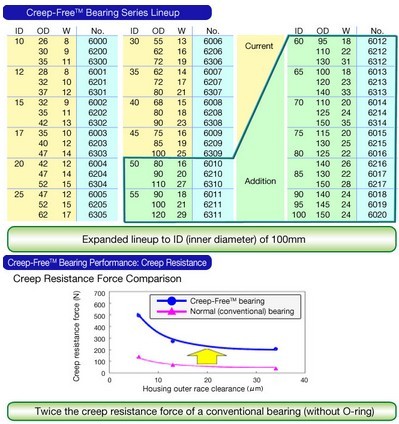

Due to the constraints of assembly, motor bearings are often used with a clearance fit*1 between the outer race and the housing. Depending on the usage conditions, if rotational load*2 is exerted on the bearing, a slip phenomenon called creep can occur between the housing and the bearing, which results in wear that can reduce the life of the bearing. In 2007, NSK launched its Creep-Free™ series of bearings of an inner diameter (ID) of 45 mm or smaller. This series has been very well received by our customers. In response to the needs from our customer base for the same kind of bearings for larger, higher output power motors, NSK has expanded its lineup to an ID of 100mm.

*1 clearance fit: Installing with a gap between the bearing, shaft and housing.

*2 rotational load: The radial load that changes the direction to the rotating shaft.

Product Features

(1) Twice the creep resistance of normal bearings (new NSK series vs. NSK conventional series)

By optimizing the O-ring and the dimensions of the groove of the outer race outer diameter where the O-ring is installed, and by tapping into the O-ring's elastic and repulsive forces, NSK has succeeded in providing a sufficient amount of tension in the fitting area between the housing and bearing to realize twice the level of creep resistance of normal bearings (new NSK series vs. NSK conventional series).

(2) Improved creep resistance under high temperatures for longer maintenance intervals

By applying a material that achieves 80% less permanent distortion in the O-ring in high temperature conditions (compared to conventional material), NSK has succeeded in achieving and maintaining a stable level of creep resistance, since there is less dimensional change due to O-ring fatigue. As a result, the maintenance interval for motors will be extended.

(3) Superior oil resistance for greater lubrication options during bearing assembly

By applying an O-ring material that achieves 87% less dimensional changes due to swelling induced by ester grease, NSK has succeeded in making it possible to use ester grease, which has high heat resistance for the outer diameter of the bearing and inner diameter of the housing. In this way, NSK has increased the number of lubrication options.

Tokyo, Japan, April 1, 2014 – NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has expanded its Creep-Free™ bearing series lineup. These bearings are widely used in fan and pump motors to prevent creep. This series of bearings is designed with exceptional creep resistance, which helps improve motor maintenance and assembly performance. NSK is targeting 1.2 billion yen in global annual sales by 2017 through this expansion to its Creep-Free™ bearing series lineup.

Due to the constraints of assembly, motor bearings are often used with a clearance fit*1 between the outer race and the housing. Depending on the usage conditions, if rotational load*2 is exerted on the bearing, a slip phenomenon called creep can occur between the housing and the bearing, which results in wear that can reduce the life of the bearing. In 2007, NSK launched its Creep-Free™ series of bearings of an inner diameter (ID) of 45 mm or smaller. This series has been very well received by our customers. In response to the needs from our customer base for the same kind of bearings for larger, higher output power motors, NSK has expanded its lineup to an ID of 100mm.

*1 clearance fit: Installing with a gap between the bearing, shaft and housing.

*2 rotational load: The radial load that changes the direction to the rotating shaft.

Product Features

(1) Twice the creep resistance of normal bearings (new NSK series vs. NSK conventional series)

By optimizing the O-ring and the dimensions of the groove of the outer race outer diameter where the O-ring is installed, and by tapping into the O-ring's elastic and repulsive forces, NSK has succeeded in providing a sufficient amount of tension in the fitting area between the housing and bearing to realize twice the level of creep resistance of normal bearings (new NSK series vs. NSK conventional series).

(2) Improved creep resistance under high temperatures for longer maintenance intervals

By applying a material that achieves 80% less permanent distortion in the O-ring in high temperature conditions (compared to conventional material), NSK has succeeded in achieving and maintaining a stable level of creep resistance, since there is less dimensional change due to O-ring fatigue. As a result, the maintenance interval for motors will be extended.

(3) Superior oil resistance for greater lubrication options during bearing assembly

By applying an O-ring material that achieves 87% less dimensional changes due to swelling induced by ester grease, NSK has succeeded in making it possible to use ester grease, which has high heat resistance for the outer diameter of the bearing and inner diameter of the housing. In this way, NSK has increased the number of lubrication options.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Blackstone Signs Deal to Purchase Gates from Onex & CPP

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.