NTN Develops “Low Section High Strength Press Pulley” for Engine Accessory Belts

Resource from: CBCC Likes:330

Jun 18,2014

[Optimally shaped design and improved press molding technology for the world's highest load resistance!]

NTN Corporation (hereafter, NTN) has developed the “Low Section High Strength Press Pulley” for engine accessory belts that delivers the world's highest load resistance.

Engine accessory belts have increased in tension in recent years due to the reduction in the number of cylinders as automotive engines decrease in size, as well as larger alternator capacities due to electrification of accessories, and idler pulleys for these belts also need to have a higher load resistance. The majority of idler pulleys are made of steel sheet, however if greater strength is required, cut iron pulleys with high load resistance or “High-load Resin Pulley*” are used. Yet cut iron pulleys require mechanical processing, while resin pulleys suffer from the issue of wear between the belt and pulley caused by penetration of foreign matter into the engine bay, particularly on rough, unpaved roads in regions such as emerging markets.

The newly developed “Low Section High Strength Press Pulley” allows for steel sheet that is 1.5-times thicker than conventional pulleys and improves the pulley load resistance two-times or more. It achieves this with an optimally shaped design established with analysis technology to avoid stress concentration during molding, as well as improvements to press molding technology. A low pulley section of approximately 70% of conventional products ensures a larger diameter bearing can be assembled, which improves bearing operating life and load capacity. Reliability is also assured by adopting existing grease that has high-temperature properties and excellent durability and was developed by NTN for bearings.

These improvements allow products to be changed over from cut iron pulleys. The product is also suited to automobiles used in emerging markets with tough usage environments where resin pulleys are difficult to use due to issues with durability under high temperature conditions, and excellent wear resistance against foreign matter.

From a monozukuri perspective, heat treatment conditions have been reviewed to improve the press mold strength and prevent damage, and special surface treatment has been applied to prevent burning on the mold during formation, both of which ensure optimum productivity.

NTN has been meeting performance requirements for light-weight, strength and reliability required of belt idler pulleys by proposing a range of resin and steel pulley products. The developed product allows product proposals that better meet these requirements, and has already been marketed to car makers. It will be released globally as a product that can contribute to better environmental performance of automotive internal combustion engines.

Features

1. 1.5-times thick steel sheets can be used compared to conventional products (steel sheet press pulleys)

Improve pulley load resistance by two-times or more

2. Low pulley section of approximately 70% of conventional products

Improves bearing life and load capacity

3. Better high-temperature durability and wear resistance against foreign matter compared to resin pulleys, for applications in automobiles for emerging markets

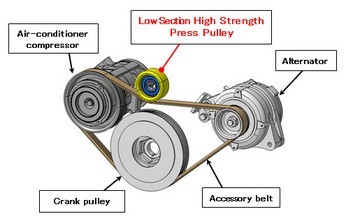

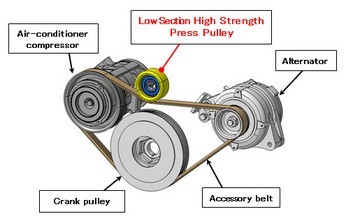

Application

Automotive engine accessory belt pulleys

Product photo

Example of applications

Example of applications

()

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.

Example of applications

Example of applications