Voith Develops High-Performance Drive

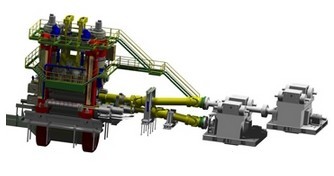

As part of its plant modernization in the heavy plate mill in Linz, Austria, Voestalpine Grobblech GmbH opted for the newly developed high-performance drive from Voith. The 'GearLink' concept, consisting of two high-performance universal joint shafts and two curved-tooth coupling shafts, was put into operation in the world's most efficient and powerful rolling mill main drive at the end of 2013. The GearLink concept enables a high level of torque transmission, unprecedented in rolling mill construction, to be achieved with very small roller diameters. This allows the operator to expand their product portfolio with further deformation processes and enables them to increase productivity while simultaneously improving quality.

The modernization of the rolling mill has made it possible to roll significantly tougher – and therefore higher quality – grades of steel with a width of up to 4.2 m. The two main drive shafts each transmit torques of 7500 kNm without fatigue based on a minimum roller diameter of 980 mm – this capacity has not previously been achieved in rolling mill construction. In contrast to conventional slipper spindles, modern universal joint crosses minimize play in the drive. Power loss as a result of friction and the environmental impact of lubricants are also kept to a minimum.

The development of the new GearLink concept is the result of close collaboration between Voestalpine Grobblech, BUMA engineering and Voith. Universal joints with a rotational diameter of 1,300 mm are used in the Voestalpine Grobblech rolling mill. The fully forged CHF 1300.8 universal joint shafts are all of varying length, which results in the shafts being offset on the roller side. This means that shafts of equal size can also be used on the roller side regardless of the roller diameter of 980 mm. The GearLink element (a curved-tooth coupling shaft) guarantees the connection between the offset shafts and the coupling sleeves. This reduces the load of bending moments on the roll journals to the greatest extent possible and allows the axial CVC (Continuous Variable Crown) displacement of the rollers. The coupling shaft also provides an axial emergency outlet in case of oblique fractures of the rollers. Voestalpine Grobblech uses materials of the highest quality to produce steel sheets which are used, for example, in the construction of pipelines.

Voith Turbo GmbH

URL: www.voith.com

As part of its plant modernization in the heavy plate mill in Linz, Austria, Voestalpine Grobblech GmbH opted for the newly developed high-performance drive from Voith. The 'GearLink' concept, consisting of two high-performance universal joint shafts and two curved-tooth coupling shafts, was put into operation in the world's most efficient and powerful rolling mill main drive at the end of 2013. The GearLink concept enables a high level of torque transmission, unprecedented in rolling mill construction, to be achieved with very small roller diameters. This allows the operator to expand their product portfolio with further deformation processes and enables them to increase productivity while simultaneously improving quality.

The modernization of the rolling mill has made it possible to roll significantly tougher – and therefore higher quality – grades of steel with a width of up to 4.2 m. The two main drive shafts each transmit torques of 7500 kNm without fatigue based on a minimum roller diameter of 980 mm – this capacity has not previously been achieved in rolling mill construction. In contrast to conventional slipper spindles, modern universal joint crosses minimize play in the drive. Power loss as a result of friction and the environmental impact of lubricants are also kept to a minimum.

The development of the new GearLink concept is the result of close collaboration between Voestalpine Grobblech, BUMA engineering and Voith. Universal joints with a rotational diameter of 1,300 mm are used in the Voestalpine Grobblech rolling mill. The fully forged CHF 1300.8 universal joint shafts are all of varying length, which results in the shafts being offset on the roller side. This means that shafts of equal size can also be used on the roller side regardless of the roller diameter of 980 mm. The GearLink element (a curved-tooth coupling shaft) guarantees the connection between the offset shafts and the coupling sleeves. This reduces the load of bending moments on the roll journals to the greatest extent possible and allows the axial CVC (Continuous Variable Crown) displacement of the rollers. The coupling shaft also provides an axial emergency outlet in case of oblique fractures of the rollers. Voestalpine Grobblech uses materials of the highest quality to produce steel sheets which are used, for example, in the construction of pipelines.

Voith Turbo GmbH

URL: www.voith.com

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.