NSK Develops RACEGRD™ Grease for bearings used in machine tool main spindles

Improved Performance Providing Energy Savings and More Space for Machining Tools

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it will launch a new grease in April 2015 that improves operation reliability for bearings used in machine tool main spindles, making it possible to operate at higher speeds and higher load conditions than with the conventional grease. NSK developed this product to help improve environmental performance and production efficiency and is targeting 4 billion yen in global sales for this product in 2016.

Development Background

Currently, oil and air lubrication is the most common kind of lubrication used for the main shafts of automobile component machining tools. The reason is that it provides for high-speed performance and reliability. However, the need for grease lubrication is increasing due to recent environmental considerations and the need for lower energy consumption.

For general-purpose machining centers where grease lubrication is common, the need for increased compactness and higher efficiency is resulting in a demand for spindle bearings that are smaller and yet have exceptional bearing performance under high load conditions.

In response to these needs, NSK has leveraged its core technology to develop RACEGRD grease to provide for higher speeds, higher load capacities and greater reliability for the main shaft bearings in machining tools.

This new grease product helps achieve greater energy savings in automobile component machining tools as well as higher efficiency and greater compactness in general-purpose machining centers by providing the following benefits.

Product Benefits

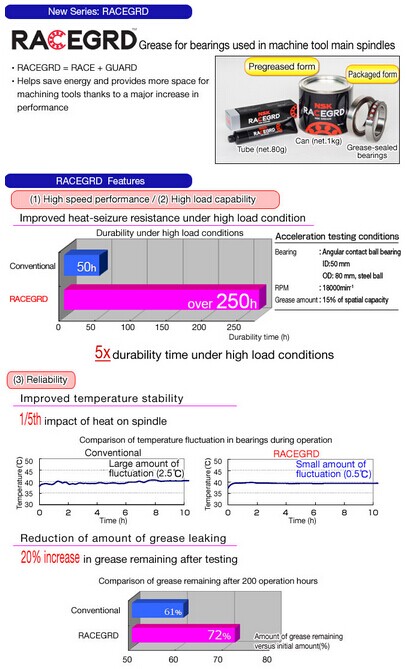

1. Higher speeds and better bearing performance for high load conditions

Improved lubrication performance under high load conditions and achieves five times the anti-seizure performance of the conventional product. Makes it possible to switch to grease lubrication in automobile component machining tools. It also helps achieve improved compactness and machining efficiency in general-purpose machining centers.

2. Greater reliability

Suppression of grease leakage from bearings, thereby reducing temperature fluctuations during operation. For vertical main shafts in particular, which are more prone to leakage, this contributes to longer grease life, higher precision operations and greater reliability for machining tools.

Improved Performance Providing Energy Savings and More Space for Machining Tools

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it will launch a new grease in April 2015 that improves operation reliability for bearings used in machine tool main spindles, making it possible to operate at higher speeds and higher load conditions than with the conventional grease. NSK developed this product to help improve environmental performance and production efficiency and is targeting 4 billion yen in global sales for this product in 2016.

Development Background

Currently, oil and air lubrication is the most common kind of lubrication used for the main shafts of automobile component machining tools. The reason is that it provides for high-speed performance and reliability. However, the need for grease lubrication is increasing due to recent environmental considerations and the need for lower energy consumption.

For general-purpose machining centers where grease lubrication is common, the need for increased compactness and higher efficiency is resulting in a demand for spindle bearings that are smaller and yet have exceptional bearing performance under high load conditions.

In response to these needs, NSK has leveraged its core technology to develop RACEGRD grease to provide for higher speeds, higher load capacities and greater reliability for the main shaft bearings in machining tools.

This new grease product helps achieve greater energy savings in automobile component machining tools as well as higher efficiency and greater compactness in general-purpose machining centers by providing the following benefits.

Product Benefits

1. Higher speeds and better bearing performance for high load conditions

Improved lubrication performance under high load conditions and achieves five times the anti-seizure performance of the conventional product. Makes it possible to switch to grease lubrication in automobile component machining tools. It also helps achieve improved compactness and machining efficiency in general-purpose machining centers.

2. Greater reliability

Suppression of grease leakage from bearings, thereby reducing temperature fluctuations during operation. For vertical main shafts in particular, which are more prone to leakage, this contributes to longer grease life, higher precision operations and greater reliability for machining tools.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.