"Wavy Nozzle" – a Newly-Introduced "Programmable Coolant System" for Small Machine Tools

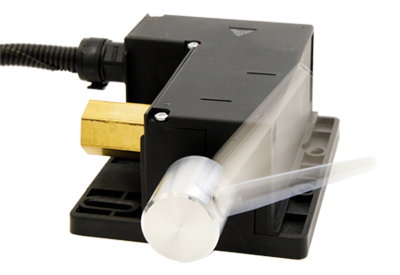

"Wavy Nozzle" made by Minebea, Product apperance in a picture (in KICK mode operation)

* 17 cases of pending applications for registration of patents and utility model rights in Japan and overseas (as of October 2014)

Notes

*1 Coolant(s)

Cutting fluids, or grinding fluids which produce a cooling or lubrication effect on the processing point in the case of machine processing

Media Inquiries: Corporate Communications Office

Phone: +81-(0)3-6758-6703 Fax: +81-(0)3-6758-6718

Information in the press releases is current on the date of the announcement.

Product information, contact and other context are subject to change without prior notice.

"Wavy Nozzle" made by Minebea, Product apperance in a picture (in KICK mode operation)

* 17 cases of pending applications for registration of patents and utility model rights in Japan and overseas (as of October 2014)

Notes

*1 Coolant(s)

Cutting fluids, or grinding fluids which produce a cooling or lubrication effect on the processing point in the case of machine processing

Media Inquiries: Corporate Communications Office

Phone: +81-(0)3-6758-6703 Fax: +81-(0)3-6758-6718

Information in the press releases is current on the date of the announcement.

Product information, contact and other context are subject to change without prior notice.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.