New whitepaper from Festo looks at considerations and tips for bearings system designers

Alternative design arrangements to cope with higher dynamic load applications

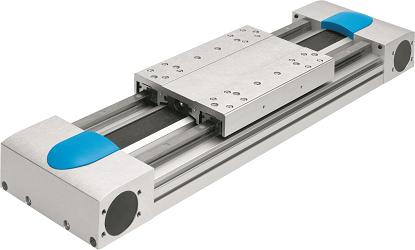

The majority of electro-mechanical axis utilise extruded aluminium profile in a range of sizes with a single guide rail and bearing arrangement driven by an electric motor through a belt or ball screw arrangement. There are physical limitations to the forces such a system can accurately and reliably guide. Festo has published a new whitepaper “Key considerations for designers looking at bearing systems with linear axes”.

The white paper can be downloaded for free from www.festo.co.uk/bearings-whitepaper and aims to help designers understand some alternative design arrangements to cope with higher load applications and identifies design considerations observed during the development of a Festo high load, twin rail system.

“Since 2008, Festo have manufactured highly successful electro-mechanical axes,” says Nigel Dawson, product manager at Festo. “We identified the opportunity to offer machine builders a single combined axis solution with a wider profile with multiple guide rails to cater for high load applications. Whilst this seemed a simple task, the reality of developing such a solution proved more challenging than first considered and highlighted some useful insights for design engineers, which are shared within this whitepaper.”

To download the new whitepaper on bearings systems, please visit www.festo.co.uk/bearings-whitepaper.

Alternative design arrangements to cope with higher dynamic load applications

The majority of electro-mechanical axis utilise extruded aluminium profile in a range of sizes with a single guide rail and bearing arrangement driven by an electric motor through a belt or ball screw arrangement. There are physical limitations to the forces such a system can accurately and reliably guide. Festo has published a new whitepaper “Key considerations for designers looking at bearing systems with linear axes”.

The white paper can be downloaded for free from www.festo.co.uk/bearings-whitepaper and aims to help designers understand some alternative design arrangements to cope with higher load applications and identifies design considerations observed during the development of a Festo high load, twin rail system.

“Since 2008, Festo have manufactured highly successful electro-mechanical axes,” says Nigel Dawson, product manager at Festo. “We identified the opportunity to offer machine builders a single combined axis solution with a wider profile with multiple guide rails to cater for high load applications. Whilst this seemed a simple task, the reality of developing such a solution proved more challenging than first considered and highlighted some useful insights for design engineers, which are shared within this whitepaper.”

To download the new whitepaper on bearings systems, please visit www.festo.co.uk/bearings-whitepaper.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next NSK's bearing design for electric motors

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.