NSK Develops New Retainer Plate Equipped Ball Bearing for Automobile Transmissions

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a new retainer plate* equipped ball bearing for automobile transmissions.

This new product can be automatically assembled thanks to a process involving the formation of a protrusion inside the retainer plate using a press machine, making it possible to fasten the retainer plate to the bearing. This new structure also makes it possible to increase engine torque and can work with a variety of plate shapes. This helps to make transmissions more compact and lighter, and it enables higher performance.

NSK is targeting 1 billion yen in global annual sales in 2018 for this product.

* Retainer plate: A plate that secures the bearing to the housing in order to restrict axial movement of the shaft and bearing.

Development Background

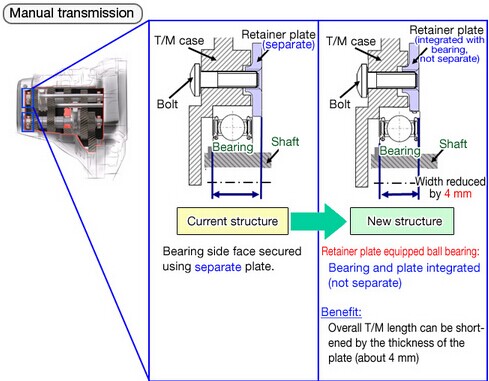

Manual transmission vehicles and dual clutch transmission vehicles are becoming more popular, especially in developing countries and Europe. The bearings used in these transmissions need to have greater rigidity to help reduce the overall length of the transmission. As a result, retainer plate equipped ball bearings are increasingly being used for such applications.

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Norio Otsuka) today announced that it has developed a new retainer plate* equipped ball bearing for automobile transmissions.

This new product can be automatically assembled thanks to a process involving the formation of a protrusion inside the retainer plate using a press machine, making it possible to fasten the retainer plate to the bearing. This new structure also makes it possible to increase engine torque and can work with a variety of plate shapes. This helps to make transmissions more compact and lighter, and it enables higher performance.

NSK is targeting 1 billion yen in global annual sales in 2018 for this product.

* Retainer plate: A plate that secures the bearing to the housing in order to restrict axial movement of the shaft and bearing.

Development Background

Manual transmission vehicles and dual clutch transmission vehicles are becoming more popular, especially in developing countries and Europe. The bearings used in these transmissions need to have greater rigidity to help reduce the overall length of the transmission. As a result, retainer plate equipped ball bearings are increasingly being used for such applications.

NSK's previous retainer plate equipped ball bearings were assembled manually with three components -the bearing, the retainer plate and the snap ring. As such, the challenge lies in improving assembly productivity. Furthermore, due to the increased use of turbo charging, the load on these bearings has increased. Also, transmissions are getting more compact and need to be able to work with a greater variety of layouts than ever before.

In response to this situation, NSK has developed a new retainer plate equipped ball bearing that possess the following advantageous features: improved productivity, increased engine output capability and accommodates a variety of transmission layouts.

Product Features

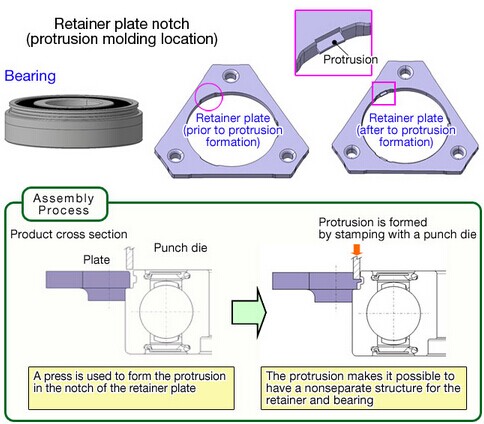

1. Automated assembly made possible

In place of a snap ring, NSK uses a press machine to form a protrusion inside the plate to fasten the plate to the bearing, thereby making automated assembly possible.

NSK's previous retainer plate equipped ball bearings were assembled manually with three components -the bearing, the retainer plate and the snap ring. As such, the challenge lies in improving assembly productivity. Furthermore, due to the increased use of turbo charging, the load on these bearings has increased. Also, transmissions are getting more compact and need to be able to work with a greater variety of layouts than ever before.

In response to this situation, NSK has developed a new retainer plate equipped ball bearing that possess the following advantageous features: improved productivity, increased engine output capability and accommodates a variety of transmission layouts.

Product Features

1. Automated assembly made possible

In place of a snap ring, NSK uses a press machine to form a protrusion inside the plate to fasten the plate to the bearing, thereby making automated assembly possible.

2. Accommodates increase in transmission gear load that comes with increased engine torque

By eliminating the need for a snap ring, NSK has been able to optimize the outer ring step shape to improve the overall strength of the structure so that it can withstand greater loads.

3. Accommodates a variety of plate shapes

NSK optimizes the location of the protrusion formed inside the plate to fasten the plate to the bearing, thereby increasing the flexibility of plate shapes, making it possible to accommodate a variety of transmission layouts.

Product Benefits

This new product helps make transmissions more compact and lighter, and it enables higher engine performance.

2. Accommodates increase in transmission gear load that comes with increased engine torque

By eliminating the need for a snap ring, NSK has been able to optimize the outer ring step shape to improve the overall strength of the structure so that it can withstand greater loads.

3. Accommodates a variety of plate shapes

NSK optimizes the location of the protrusion formed inside the plate to fasten the plate to the bearing, thereby increasing the flexibility of plate shapes, making it possible to accommodate a variety of transmission layouts.

Product Benefits

This new product helps make transmissions more compact and lighter, and it enables higher engine performance.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Saint-Gobain Seals releases two new product handbooks: OmniSeal® spring-energized seals (US or EU) and Meldin® HT thermoplastic materials

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.