Schaeffler India develops clutchless gear system for cars(pic)

Schaeffler India's Efficient Future Mobility India concept car is equipped with an ECM prototype in combination with a start-stop system.

Schaeffler India, the local arm of the 12.1 billion euro Schaeffler Group, is currently running a market research program in association with Frost & Sullivan to closely understand possible transmission preferences of the Indian passenger car drivers.

The company is doing so by demonstrating various transmission technologies equipped on its concept cars. These systems include the conventional automatic transmission system (AT), continuously variable transmission system (CVT), automated transmission system (AMT), electronic clutch management system (ECM) and dual clutch transmission system (DCT).

Of these, while the AMT has gained substantial traction lately, all thanks to Maruti Suzuki’s top-end Celerio variant, the ECM can be another typical low-cost transmission solution for the Indian passenger car market.

Experts say that the ECM can be positioned below the AMT in terms of production, integration and calibration costs. This clearly underlines a wide scope of ECM applications in entry-level variants of hatchbacks, sedans and SUVs in the near future, considering that OEMs give a nod to the same.

Picking up one of the best-selling premium hatchbacks in India and equipping it with a prototype of an in-house- developed ECM system, Schaeffler India has come up with a few proven advantages via innovative features, components and subsystems.

“We developed an electronic clutch management system specifically for the traffic conditions typical for India for the Efficient Future Mobility India concept car,” Dharmesh Arora, president and CEO, Schaeffler India, told Autocar Professional.

Schaeffler India's Efficient Future Mobility India concept car is equipped with an ECM prototype in combination with a start-stop system.

Schaeffler India, the local arm of the 12.1 billion euro Schaeffler Group, is currently running a market research program in association with Frost & Sullivan to closely understand possible transmission preferences of the Indian passenger car drivers.

The company is doing so by demonstrating various transmission technologies equipped on its concept cars. These systems include the conventional automatic transmission system (AT), continuously variable transmission system (CVT), automated transmission system (AMT), electronic clutch management system (ECM) and dual clutch transmission system (DCT).

Of these, while the AMT has gained substantial traction lately, all thanks to Maruti Suzuki’s top-end Celerio variant, the ECM can be another typical low-cost transmission solution for the Indian passenger car market.

Experts say that the ECM can be positioned below the AMT in terms of production, integration and calibration costs. This clearly underlines a wide scope of ECM applications in entry-level variants of hatchbacks, sedans and SUVs in the near future, considering that OEMs give a nod to the same.

Picking up one of the best-selling premium hatchbacks in India and equipping it with a prototype of an in-house- developed ECM system, Schaeffler India has come up with a few proven advantages via innovative features, components and subsystems.

“We developed an electronic clutch management system specifically for the traffic conditions typical for India for the Efficient Future Mobility India concept car,” Dharmesh Arora, president and CEO, Schaeffler India, told Autocar Professional.

What is an ECM?

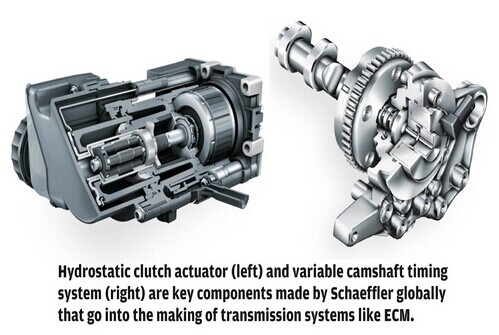

To put it simply, an ECM is a manual transmission system without the clutch pedal. The clutch pedal in the ECM is replaced by an actuator. One of the most important components of the system is the self-adjusting clutch (SAC), an electromotive clutch actuator with integrated control and power electronics, intelligent control strategies such as torque tracking and limiting the number of sensors used.

The driver can continue to shift gears manually while driving. The sensors detect the intention and opens up the clutch for the function. Besides increased driving comfort, the optimum automation and intelligent software solutions of the ECM system allow significant reductions in outlay and cost savings to be made compared with a completely automated manual transmission.

A company document says that “compared with that of an automated manual transmission where an additional electromotive transmission actuator is used, the drive comfort can even be improved by means of the interruption to tractive force actively triggered by the driver when the gearshift lever is operated.”

“With the ECM, the driver still carries out the gearshift operation in the same way as with a manual transmission, but the actuator system activates the clutch instead. The costs are, of course, considerably lower than those of an automated manual transmission due to the elimination of the automated gearshift system,” said Arora.

What is an ECM?

To put it simply, an ECM is a manual transmission system without the clutch pedal. The clutch pedal in the ECM is replaced by an actuator. One of the most important components of the system is the self-adjusting clutch (SAC), an electromotive clutch actuator with integrated control and power electronics, intelligent control strategies such as torque tracking and limiting the number of sensors used.

The driver can continue to shift gears manually while driving. The sensors detect the intention and opens up the clutch for the function. Besides increased driving comfort, the optimum automation and intelligent software solutions of the ECM system allow significant reductions in outlay and cost savings to be made compared with a completely automated manual transmission.

A company document says that “compared with that of an automated manual transmission where an additional electromotive transmission actuator is used, the drive comfort can even be improved by means of the interruption to tractive force actively triggered by the driver when the gearshift lever is operated.”

“With the ECM, the driver still carries out the gearshift operation in the same way as with a manual transmission, but the actuator system activates the clutch instead. The costs are, of course, considerably lower than those of an automated manual transmission due to the elimination of the automated gearshift system,” said Arora.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next SKF signs strategic agreement with ReGen Powertech

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.