Schaeffler supplies monorail guides for Airbus A350 wing assembly jigs (pic)

Precision bearing manufacturer Schaeffler (UK) Ltd has supplied a variety of monorail guidance systems to Electroimpact, a global provider of aircraft assembly lines, factory automation and tooling solutions. The linear guidance systems form part of the assembly jigs for the Airbus A350 wings, which are currently being assembled at the Airbus site in Broughton, UK.

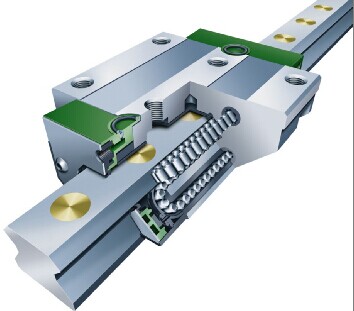

Schaeffler supplied several hundred units from its RUE-E series of linear recirculating roller bearings and guideway assemblies, including carriages, rails and other linear accessories. These units were supplied in various sizes (25, 35, 45, 55, 65 and 100) and in various types (standard, long, high and high long). The RUE-E series is suitable for applications in which extremely heavy loads need to be supported and where high rigidity and precise travel are required.

Schaeffler also supplied units from its KUVE-B series of ball monorail guidance systems. These are four-row linear recirculating ball bearing and guideway assemblies. These units are used where linear guidance systems with high load carrying capacity and rigidity are required to move heavy loads with high running and positional accuracy, as well as low friction. The guidance systems are preloaded and are suitable for long, unlimited stroke lengths.

Founded in 1986, Electroimpact’s main campus and head office is located in Mukilteo, Washington, USA. The company also has a satellite office in Broughton, UK with over 100 engineers.

As Lucas Sallee, design engineer at Electroimpact Inc. states: “The linear guidance systems were chosen based on their superior cost and lead time on the logistics side. However, we also selected the linear guides due to their alternate roller arrangements, which leave more space for lubrication access channels, and end cap design. During routine maintenance, this design allows for superior ingress of grease onto the roller elements when stationary. In our experience, other linear guide manufacturers design their end caps primarily for oil lubrication with limited access channels from zirc fitting roller element, resulting in grease squeezing out of the end cap to the bearing block junction rather than entering the roller cavities.“

For more information on Schaeffler’s range of monorail guidance systems, please contact Schaeffler UK’s Communications & Marketing Department on info.uk@schaeffler.com.

Precision bearing manufacturer Schaeffler (UK) Ltd has supplied a variety of monorail guidance systems to Electroimpact, a global provider of aircraft assembly lines, factory automation and tooling solutions. The linear guidance systems form part of the assembly jigs for the Airbus A350 wings, which are currently being assembled at the Airbus site in Broughton, UK.

Schaeffler supplied several hundred units from its RUE-E series of linear recirculating roller bearings and guideway assemblies, including carriages, rails and other linear accessories. These units were supplied in various sizes (25, 35, 45, 55, 65 and 100) and in various types (standard, long, high and high long). The RUE-E series is suitable for applications in which extremely heavy loads need to be supported and where high rigidity and precise travel are required.

Schaeffler also supplied units from its KUVE-B series of ball monorail guidance systems. These are four-row linear recirculating ball bearing and guideway assemblies. These units are used where linear guidance systems with high load carrying capacity and rigidity are required to move heavy loads with high running and positional accuracy, as well as low friction. The guidance systems are preloaded and are suitable for long, unlimited stroke lengths.

Founded in 1986, Electroimpact’s main campus and head office is located in Mukilteo, Washington, USA. The company also has a satellite office in Broughton, UK with over 100 engineers.

As Lucas Sallee, design engineer at Electroimpact Inc. states: “The linear guidance systems were chosen based on their superior cost and lead time on the logistics side. However, we also selected the linear guides due to their alternate roller arrangements, which leave more space for lubrication access channels, and end cap design. During routine maintenance, this design allows for superior ingress of grease onto the roller elements when stationary. In our experience, other linear guide manufacturers design their end caps primarily for oil lubrication with limited access channels from zirc fitting roller element, resulting in grease squeezing out of the end cap to the bearing block junction rather than entering the roller cavities.“

For more information on Schaeffler’s range of monorail guidance systems, please contact Schaeffler UK’s Communications & Marketing Department on info.uk@schaeffler.com.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.