Non-contact torque sensors from Schaeffler improve control precision (pic)

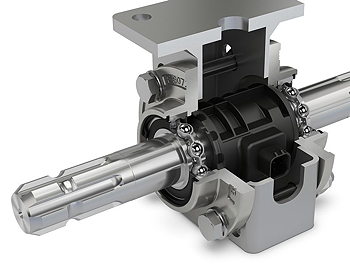

A cutaway view of Schaeffler’s torque-sensing module

The first applications for the new technology are in the agricultural sector, such as fertiliser spreaders, where they are being used to monitor parameters such as the speed and torque of take-off shafts, and to feed this data to the control system to optimise performance.

A cutaway view of Schaeffler’s torque-sensing module

The first applications for the new technology are in the agricultural sector, such as fertiliser spreaders, where they are being used to monitor parameters such as the speed and torque of take-off shafts, and to feed this data to the control system to optimise performance.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next H Lange resigns as Director of SKF India Ltd

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.