Bearing sensor could let wind-turbines bearings talk

Subjecting a bearing to a load reduces a dimension by a small amount due to elastic deformation. So the stress level in the bearing affects the speed of sound in the material which provides a wear indication.

A method, published in the journal Proceedings of the Royal Society and developed by Mechanical Engineering research student Wenqu Chen, uses ultrasonic waves to measure the load transmitted through a ball bearing in a wind turbine. The stress on wind turbine is recorded which lets engineers forecast its remaining service life.

When a bearing is subject to a load, its thickness is reduced by a small amount due to elastic deformation, which also affects the speed of sound by the stress level in the material. Both these effects change the travel time of an ultrasound wave through a bearing.

Researchers say the method is the only way to directly measure the transmitted load through rolling bearing components. The device uses a custom-built piezoelectric sensor mounted in the bearing to measure the time of flight and determine the load. The sensor is less expensive and significantly smaller than others currently available, making it suitable for smaller turbines. It can also provide a better prediction of the maintenance needed.

Subjecting a bearing to a load reduces a dimension by a small amount due to elastic deformation. So the stress level in the bearing affects the speed of sound in the material which provides a wear indication.

A method, published in the journal Proceedings of the Royal Society and developed by Mechanical Engineering research student Wenqu Chen, uses ultrasonic waves to measure the load transmitted through a ball bearing in a wind turbine. The stress on wind turbine is recorded which lets engineers forecast its remaining service life.

When a bearing is subject to a load, its thickness is reduced by a small amount due to elastic deformation, which also affects the speed of sound by the stress level in the material. Both these effects change the travel time of an ultrasound wave through a bearing.

Researchers say the method is the only way to directly measure the transmitted load through rolling bearing components. The device uses a custom-built piezoelectric sensor mounted in the bearing to measure the time of flight and determine the load. The sensor is less expensive and significantly smaller than others currently available, making it suitable for smaller turbines. It can also provide a better prediction of the maintenance needed.

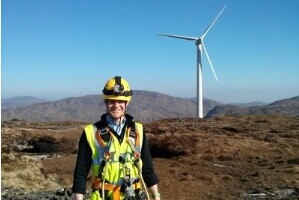

The Professor poses with a test turbine.

Professor Rob Dwyer-Joyce, co-author of the paper and Director of the Leonardo Centre for Tribology at the University of Sheffield says: “This technique can be used to prevent unexpected bearing failures, which are a common problem in wind turbines. By removing the risk of a loss of production and the need for unplanned maintenance, it can help to reduce the cost of wind energy and make it much more economically competitive.

The new technology has been validated in the lab and is currently being tested at the Barnesmore wind farm in Donegal, Ireland by the company Ricardo.

The Professor poses with a test turbine.

Professor Rob Dwyer-Joyce, co-author of the paper and Director of the Leonardo Centre for Tribology at the University of Sheffield says: “This technique can be used to prevent unexpected bearing failures, which are a common problem in wind turbines. By removing the risk of a loss of production and the need for unplanned maintenance, it can help to reduce the cost of wind energy and make it much more economically competitive.

The new technology has been validated in the lab and is currently being tested at the Barnesmore wind farm in Donegal, Ireland by the company Ricardo.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.