What criteria should be considered when selecting lubricants for wind turbines?

For a high-performing gearbox, choose a synthetic gear lubricant that offers water resistance, anti-foaming properties, and filterability.

Oil and other lubricants play important roles in keeping today’s wind turbines running reliably and efficiently. Because of the extreme conditions most turbines face and number of different parts that require lubrication, there is no specified set of criteria for choosing the right product, which makes careful section essential.

“There is no ‘one size fits all’ when it comes to proper lubrication for a turbine,” said Kevin Dinwiddie, Sr. Wind Turbine Tribologist at AMSOIL. “For example, there is gear oil for the main gearbox and pitch and yaw gearboxes, hydraulic oil for pitch systems and brake stations, and greases for the pitch bearings, yaw gears, generator bearings, main bearings, and more.”

Selection requires a long list of considerations. For instance, you’re looking for an oil’s ability to reduce wear, resist water and corrosion, control or eliminate foam, and remain in viscosity,” said Dinwiddie. He added that many oils can pass manufacturer laboratory tests, so it’s important to evaluate field test data and consider potential product warranties. “This means an oil or lubricant should offer real-life data and proven results.”

According to the Society of Tribologists and Lubrication Engineers, viscosity is one of an oil’s most important physical properties and often one of the first parameters measured by analysis labs. It refers to an oil’s ability to resist flow and shear related to gravity and internal friction.

Fortunately, Dinwiddie said, lubricant quality has increased substantially in recent years, which has led to more reliable formulations that directly impact turbine O&M. “Today’s chemistries have increased lubricant oil-drain intervals from three to seven years, and possibly even longer.”

A longer service life means fewer oil changes and less maintenance costs. What’s more is many of today’s lubricants are safer for the environment, which is an important consideration when selecting a turbine oil. “Synthetic gear oils don’t contain the impurities that mineral or petroleum oils contain, such as waxes,” he said.

Unlike mineral oils, synthetic oils are manufactured by adding together identical molecules to obtain oils of varying levels of viscosity. “Another important consideration is to use synthetic oil for longer oil-drain intervals, which results in less waste,” added Dinwiddie. Synthetics also perform at much lower ambient temperatures than traditional gear oils, which is important because of the cold temperatures turbines must perform in without failure.

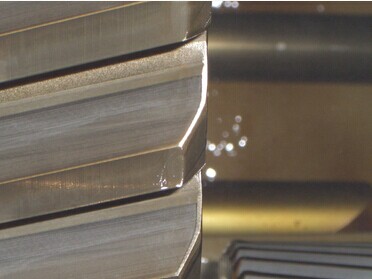

Dinwiddie suggests choosing an oil with extreme-pressure additives that exhibits a high level of viscosity retention to minimize micropitting and scuffing wear. Micropitting refers to localized surface damage that’s prevalent in turbine gearboxes and can occur on gear teeth and bearings.

“Even water, for example, is one of the biggest contributors to gearbox failure. It can cause additive drop-outs, viscosity losses, sludge formation, and filter plugging.” But a synthetic molecule’s structure is stronger and more resistant to stresses, such as high temperatures and oxidation, resulting in reduced friction and longer oil life.

“Often synthetic oils cost a bit more,” said Dinwiddie. “But in the end you get what you pay for and, in this case, it’s a turbine with a longer life that requires less maintenance.”

For a high-performing gearbox, choose a synthetic gear lubricant that offers water resistance, anti-foaming properties, and filterability.

Oil and other lubricants play important roles in keeping today’s wind turbines running reliably and efficiently. Because of the extreme conditions most turbines face and number of different parts that require lubrication, there is no specified set of criteria for choosing the right product, which makes careful section essential.

“There is no ‘one size fits all’ when it comes to proper lubrication for a turbine,” said Kevin Dinwiddie, Sr. Wind Turbine Tribologist at AMSOIL. “For example, there is gear oil for the main gearbox and pitch and yaw gearboxes, hydraulic oil for pitch systems and brake stations, and greases for the pitch bearings, yaw gears, generator bearings, main bearings, and more.”

Selection requires a long list of considerations. For instance, you’re looking for an oil’s ability to reduce wear, resist water and corrosion, control or eliminate foam, and remain in viscosity,” said Dinwiddie. He added that many oils can pass manufacturer laboratory tests, so it’s important to evaluate field test data and consider potential product warranties. “This means an oil or lubricant should offer real-life data and proven results.”

According to the Society of Tribologists and Lubrication Engineers, viscosity is one of an oil’s most important physical properties and often one of the first parameters measured by analysis labs. It refers to an oil’s ability to resist flow and shear related to gravity and internal friction.

Fortunately, Dinwiddie said, lubricant quality has increased substantially in recent years, which has led to more reliable formulations that directly impact turbine O&M. “Today’s chemistries have increased lubricant oil-drain intervals from three to seven years, and possibly even longer.”

A longer service life means fewer oil changes and less maintenance costs. What’s more is many of today’s lubricants are safer for the environment, which is an important consideration when selecting a turbine oil. “Synthetic gear oils don’t contain the impurities that mineral or petroleum oils contain, such as waxes,” he said.

Unlike mineral oils, synthetic oils are manufactured by adding together identical molecules to obtain oils of varying levels of viscosity. “Another important consideration is to use synthetic oil for longer oil-drain intervals, which results in less waste,” added Dinwiddie. Synthetics also perform at much lower ambient temperatures than traditional gear oils, which is important because of the cold temperatures turbines must perform in without failure.

Dinwiddie suggests choosing an oil with extreme-pressure additives that exhibits a high level of viscosity retention to minimize micropitting and scuffing wear. Micropitting refers to localized surface damage that’s prevalent in turbine gearboxes and can occur on gear teeth and bearings.

“Even water, for example, is one of the biggest contributors to gearbox failure. It can cause additive drop-outs, viscosity losses, sludge formation, and filter plugging.” But a synthetic molecule’s structure is stronger and more resistant to stresses, such as high temperatures and oxidation, resulting in reduced friction and longer oil life.

“Often synthetic oils cost a bit more,” said Dinwiddie. “But in the end you get what you pay for and, in this case, it’s a turbine with a longer life that requires less maintenance.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Eaton aftermarket clutches get additional warranty option

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.