Maplesoft Engineering Solutions Team Helps FLSmidth Develop Revolutionary Mining Equipment

FLSmidth recently kept their design of an innovative machine on track, and saved millions of dollars down the line when they consulted the services of Maplesoft's Engineering Solutions team.

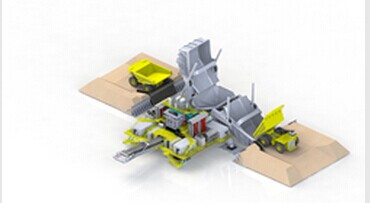

FLSmidth’s Dual Truck Mobile Sizer, designed with help from Maplesoft.

The level of design detail and the amount of insight we gained have enabled us to revolutionize onsite crushing through the development of the DTMS. We could not have achieved this without the services of Maplesoft’s Engineering Solutions team.

(PRWEB) SEPTEMBER 16, 2015

In the mining industry, processing plants are generally constructed on the site of extraction. Mined ore gets transported by super-heavy duty trucks to the plant, where it gets crushed into smaller sizes before being stockpiled, or transported offsite for further processing. Besides the ore, the mine typically has to move four times as much overburden as ore. Big mines typically have to move 700,000 tonne of material per day. As the mine gets larger, the trucks have to travel longer distances to deposit their load, resulting in significant increases in the cost of fuel and vehicle maintenance.

To address this problem, FLSmidth engaged the services of Maplesoft’s Engineering Solutions team to develop design and analysis tools that would help them design a Dual Truck Mobile Sizer (DTMS) - an innovative machine that can be relocated throughout a project, as the haul distances increase.

The DTMS increases in-pit crushing efficiency due to its dual-skip configuration. A truck backs into one skip until it reaches a restraining curb in the floor. After dumping its load on the skip floor, it then slowly pulls ahead, lowers its bed, and pulls away. Once the truck clears the end of the skip, the skip can be raised. As the skip is elevated, it pours material from the discharge of the skip and deposits the material into the apron feeder hopper. As material is introduced onto the apron feeder, it conveys the material to the sizer where it is crushed to the appropriate size. After being crushed, the material is deposited onto the discharge conveyor where it is taken to the bench conveyor. This process is performed while another haul truck is depositing material into the twin skip, thereby increasing the number of truck cycles.

To create tools that would help FLSmidth to design this innovative piece of equipment, the Maplesoft team first had to develop a deep understanding of the dynamics of the skip system. They began by using MapleSim, the advanced modeling and simulation platform, to develop a fully parameterized model of the skip. Taking advantage of MapleSim’s multidomain modeling capabilities, they were able to create a high-fidelity model that incorporated all the key components of the skip - from its geometric structure and mechanical operation, to the hydraulic circuits and controllers. “The DTMS is a very large and complex machine,” says Willem Fourie, Global Product Line Manager - Mobile Sizer Stations, FLSmidth. “The ability to model all aspects of its operation during the design phase using MapleSim gave us confidence that the product we would ultimately build would function correctly the first time. We cannot even begin to put a value on what this means to us.”

MapleSim’s modeling approach not only addresses the basic requirements of dynamic multidomain simulation, but through seamless access to the underlying symbolic equations, enables the user to rapidly create targeted design tools using Maple’s high-performance symbolic computation engine.

The creation of the skip model was complemented with the development of multiple design tools to aid in adjusting the model to achieve the desired behavior. One such design tool is the Geometric Design Evaluation tool, which provides the ability to evaluate changes in the dimensions of the skip design and their effect on the dynamics of the system. The tool uses Maple - Maplesoft’s symbolic computation tool - to perform a parameter sweep, by simultaneously running simulations using the different parameter values provided. Maple then presents the results overlaid on a single plot window for easy comparison and evaluation. Other tools developed include tools for sizing the hydraulics and components, designing the motion profile, investigating the dynamic loading on the bearings, and estimating the material flow load.

As part of developing and testing the skip model, Maplesoft’s technical team also evaluated the design, to identify the sources of vibrations and their effects. They developed an approach to perform stability analysis, which was made possible by the fact that the skip model provided easy access to key geometric features and dynamic properties of the design. The stability analysis approach was demonstrated using a case study in which the location of the feedback sensor was varied. The analysis identified a potential issue very early in the design phase, enabling engineers at FLSmidth to develop a more robust design.

“The stability analysis performed by the Maplesoft team was very insightful,” said Fourie. “Knowing about a potential issue early on enabled us to design with it in mind, rather than having to go back and rework our design at a later stage. This contributed to keeping our project on track, and saved us millions of dollars down the line.” The stability analysis design approach and all the other analysis tools developed by Maplesoft were delivered to FLSmidth, enabling them to apply them to future projects.

Once the modeling and testing of the skip system was completed, during the following phases of the project, Maplesoft staff went on to develop the chassis model, and finally the full DTMS. Many more design tools were created, providing the ability to evaluate joint flexibility, center of mass variations as the skip was raised and lowered, and even soil modeling to investigate the vertical displacement of the system on different types of soil.

“From start to finish, Maplesoft provided truly knowledgeable and professional service,” concludes Fourie. “Their team worked tirelessly to accommodate our schedule, and the power of the Maplesoft toolset is second to none. The level of design detail and the amount of insight we gained have enabled us to revolutionize onsite crushing through the development of the DTMS. We could not have achieved this without the services of Maplesoft’s Engineering Solutions team.”

About Maplesoft

Maplesoft™, a subsidiary of Cybernet Systems Co., Ltd. in Japan, is the leading provider of high-performance software tools for engineering, science, and mathematics. Its product suite reflects the philosophy that given great tools, people can do great things.

Maplesoft’s core technologies include the world’s most advanced symbolic computation engine and revolutionary system-level modeling techniques. Combined, these technologies provide cutting-edge solutions for design, modeling, and high-performance simulation.

Maplesoft’s products help to reduce errors, shorten design times, lower costs, and improve results. The Maplesoft product suite includes Maple™, the technical computing and documentation environment, and MapleSim™, the high-performance, multi-domain modeling and simulation tool for physical systems.

Engineers, scientists, and mathematicians use Maplesoft products to enable them to work better, faster, and smarter. Maplesoft’s customers include Ford, Bosch, Boeing, NASA, Canadian Space Agency, Canon and Motorola, covering sectors such as automotive, aerospace, electronics, defense, energy, financial services, consumer products, and entertainment. With Toyota, Maplesoft founded the Plant Modeling Consortium to promote the development of new design techniques for automotive and related industries.

Visit http://www.maplesoft.com to learn more.

About Cybernet Systems Co., Ltd.

CYBERNET SYSTEMS in Japan provides world-class solutions and services in the CAE and IT areas. For more information, visit http://www.cybernet.co.jp/english/

FLSmidth recently kept their design of an innovative machine on track, and saved millions of dollars down the line when they consulted the services of Maplesoft's Engineering Solutions team.

FLSmidth’s Dual Truck Mobile Sizer, designed with help from Maplesoft.

The level of design detail and the amount of insight we gained have enabled us to revolutionize onsite crushing through the development of the DTMS. We could not have achieved this without the services of Maplesoft’s Engineering Solutions team.

(PRWEB) SEPTEMBER 16, 2015

In the mining industry, processing plants are generally constructed on the site of extraction. Mined ore gets transported by super-heavy duty trucks to the plant, where it gets crushed into smaller sizes before being stockpiled, or transported offsite for further processing. Besides the ore, the mine typically has to move four times as much overburden as ore. Big mines typically have to move 700,000 tonne of material per day. As the mine gets larger, the trucks have to travel longer distances to deposit their load, resulting in significant increases in the cost of fuel and vehicle maintenance.

To address this problem, FLSmidth engaged the services of Maplesoft’s Engineering Solutions team to develop design and analysis tools that would help them design a Dual Truck Mobile Sizer (DTMS) - an innovative machine that can be relocated throughout a project, as the haul distances increase.

The DTMS increases in-pit crushing efficiency due to its dual-skip configuration. A truck backs into one skip until it reaches a restraining curb in the floor. After dumping its load on the skip floor, it then slowly pulls ahead, lowers its bed, and pulls away. Once the truck clears the end of the skip, the skip can be raised. As the skip is elevated, it pours material from the discharge of the skip and deposits the material into the apron feeder hopper. As material is introduced onto the apron feeder, it conveys the material to the sizer where it is crushed to the appropriate size. After being crushed, the material is deposited onto the discharge conveyor where it is taken to the bench conveyor. This process is performed while another haul truck is depositing material into the twin skip, thereby increasing the number of truck cycles.

To create tools that would help FLSmidth to design this innovative piece of equipment, the Maplesoft team first had to develop a deep understanding of the dynamics of the skip system. They began by using MapleSim, the advanced modeling and simulation platform, to develop a fully parameterized model of the skip. Taking advantage of MapleSim’s multidomain modeling capabilities, they were able to create a high-fidelity model that incorporated all the key components of the skip - from its geometric structure and mechanical operation, to the hydraulic circuits and controllers. “The DTMS is a very large and complex machine,” says Willem Fourie, Global Product Line Manager - Mobile Sizer Stations, FLSmidth. “The ability to model all aspects of its operation during the design phase using MapleSim gave us confidence that the product we would ultimately build would function correctly the first time. We cannot even begin to put a value on what this means to us.”

MapleSim’s modeling approach not only addresses the basic requirements of dynamic multidomain simulation, but through seamless access to the underlying symbolic equations, enables the user to rapidly create targeted design tools using Maple’s high-performance symbolic computation engine.

The creation of the skip model was complemented with the development of multiple design tools to aid in adjusting the model to achieve the desired behavior. One such design tool is the Geometric Design Evaluation tool, which provides the ability to evaluate changes in the dimensions of the skip design and their effect on the dynamics of the system. The tool uses Maple - Maplesoft’s symbolic computation tool - to perform a parameter sweep, by simultaneously running simulations using the different parameter values provided. Maple then presents the results overlaid on a single plot window for easy comparison and evaluation. Other tools developed include tools for sizing the hydraulics and components, designing the motion profile, investigating the dynamic loading on the bearings, and estimating the material flow load.

As part of developing and testing the skip model, Maplesoft’s technical team also evaluated the design, to identify the sources of vibrations and their effects. They developed an approach to perform stability analysis, which was made possible by the fact that the skip model provided easy access to key geometric features and dynamic properties of the design. The stability analysis approach was demonstrated using a case study in which the location of the feedback sensor was varied. The analysis identified a potential issue very early in the design phase, enabling engineers at FLSmidth to develop a more robust design.

“The stability analysis performed by the Maplesoft team was very insightful,” said Fourie. “Knowing about a potential issue early on enabled us to design with it in mind, rather than having to go back and rework our design at a later stage. This contributed to keeping our project on track, and saved us millions of dollars down the line.” The stability analysis design approach and all the other analysis tools developed by Maplesoft were delivered to FLSmidth, enabling them to apply them to future projects.

Once the modeling and testing of the skip system was completed, during the following phases of the project, Maplesoft staff went on to develop the chassis model, and finally the full DTMS. Many more design tools were created, providing the ability to evaluate joint flexibility, center of mass variations as the skip was raised and lowered, and even soil modeling to investigate the vertical displacement of the system on different types of soil.

“From start to finish, Maplesoft provided truly knowledgeable and professional service,” concludes Fourie. “Their team worked tirelessly to accommodate our schedule, and the power of the Maplesoft toolset is second to none. The level of design detail and the amount of insight we gained have enabled us to revolutionize onsite crushing through the development of the DTMS. We could not have achieved this without the services of Maplesoft’s Engineering Solutions team.”

About Maplesoft

Maplesoft™, a subsidiary of Cybernet Systems Co., Ltd. in Japan, is the leading provider of high-performance software tools for engineering, science, and mathematics. Its product suite reflects the philosophy that given great tools, people can do great things.

Maplesoft’s core technologies include the world’s most advanced symbolic computation engine and revolutionary system-level modeling techniques. Combined, these technologies provide cutting-edge solutions for design, modeling, and high-performance simulation.

Maplesoft’s products help to reduce errors, shorten design times, lower costs, and improve results. The Maplesoft product suite includes Maple™, the technical computing and documentation environment, and MapleSim™, the high-performance, multi-domain modeling and simulation tool for physical systems.

Engineers, scientists, and mathematicians use Maplesoft products to enable them to work better, faster, and smarter. Maplesoft’s customers include Ford, Bosch, Boeing, NASA, Canadian Space Agency, Canon and Motorola, covering sectors such as automotive, aerospace, electronics, defense, energy, financial services, consumer products, and entertainment. With Toyota, Maplesoft founded the Plant Modeling Consortium to promote the development of new design techniques for automotive and related industries.

Visit http://www.maplesoft.com to learn more.

About Cybernet Systems Co., Ltd.

CYBERNET SYSTEMS in Japan provides world-class solutions and services in the CAE and IT areas. For more information, visit http://www.cybernet.co.jp/english/

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.