Energy Department awards $1.8 million to develop wind turbine blades to access better wind resources and reduce costs

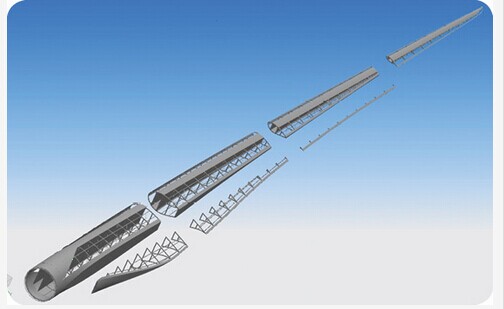

Wetzel Engineering, Inc. of Pflugerville, Texas, in partnership with the Energy Department’s National Renewable Energy Laboratory (NREL), Northern Power Systems, TPI Composites, and NextEra, will develop a field-assembled blade called “SparBlade using a lightweight bonded composite space frame. Between 62–74 meters, this new technology is intended for operation on multi-megawatt wind turbines and tall towers. The new technology is expected to create a higher performance, lower weight, and lower cost wind turbine blade with significantly reduced transportation costs.

General Electric (GE), in partnership with NREL and TPI Composites, will design a jointed blade for onsite assembly to reduce transportation logistical constraints while meeting structural requirements for next-generation turbines. GE will gather input and engage industry to facilitate technology transfer as jointed blades are introduced in the United States.

This effort is part of the Department’s Clean Energy Manufacturing Initiative, which aims to increase American competitiveness in the production of clean energy products and boost U.S. manufacturing competitiveness across the board by increasing energy productivity.

The Energy Department’s Office of Energy Efficiency and Renewable Energy accelerates development and deployment of energy efficiency and renewable energy technologies and market-based solutions that strengthen U.S. energy security, environmental quality, and economic vitality. Learn more about the Wind Program’s research and development efforts to advance wind turbine and component manufacturing.

The Energy Department today announced the selection of two organizations to develop larger wind turbine blades that can take advantage of better wind resources and can lower costs. Technological innovations such as taller wind turbine towers and larger rotors can more efficiently capture the stronger and more consistent wind resources typically found at greater heights above ground level. This past May, the Energy Department released a new report highlighting how the United States can unlock the vast potential for wind energy deployment in all 50 states, made possible through continued innovations in next-generation components like these.

Wetzel Engineering, Inc. of Pflugerville, Texas, in partnership with the Energy Department’s National Renewable Energy Laboratory (NREL), Northern Power Systems, TPI Composites, and NextEra, will develop a field-assembled blade called “SparBlade using a lightweight bonded composite space frame. Between 62–74 meters, this new technology is intended for operation on multi-megawatt wind turbines and tall towers. The new technology is expected to create a higher performance, lower weight, and lower cost wind turbine blade with significantly reduced transportation costs.

General Electric (GE), in partnership with NREL and TPI Composites, will design a jointed blade for onsite assembly to reduce transportation logistical constraints while meeting structural requirements for next-generation turbines. GE will gather input and engage industry to facilitate technology transfer as jointed blades are introduced in the United States.

This effort is part of the Department’s Clean Energy Manufacturing Initiative, which aims to increase American competitiveness in the production of clean energy products and boost U.S. manufacturing competitiveness across the board by increasing energy productivity.

The Energy Department’s Office of Energy Efficiency and Renewable Energy accelerates development and deployment of energy efficiency and renewable energy technologies and market-based solutions that strengthen U.S. energy security, environmental quality, and economic vitality. Learn more about the Wind Program’s research and development efforts to advance wind turbine and component manufacturing.

The Energy Department today announced the selection of two organizations to develop larger wind turbine blades that can take advantage of better wind resources and can lower costs. Technological innovations such as taller wind turbine towers and larger rotors can more efficiently capture the stronger and more consistent wind resources typically found at greater heights above ground level. This past May, the Energy Department released a new report highlighting how the United States can unlock the vast potential for wind energy deployment in all 50 states, made possible through continued innovations in next-generation components like these.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.