NSK Releases High-Performance Precision Ball Screw

Resource from: NSK Likes:267

Oct 09,2015

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it is releasing a high-performance precision ball screw based on new technology designed for machine tool high-performance ball screws that it announced in October 2014. This technology features a huge improvement in ball screw motion control. NSK will launch this new product in October 2015 targeting 2 billion yen in global sales in 2018.

NSK Ltd. will exhibit this product at MECHATRONICS TECHNOLOGY (MECT) JAPAN 2015 to be held at Port Messe Nagoya (Nagoya Int'l Exhibition Hall) in Japan from October 21 to October 24, 2015.

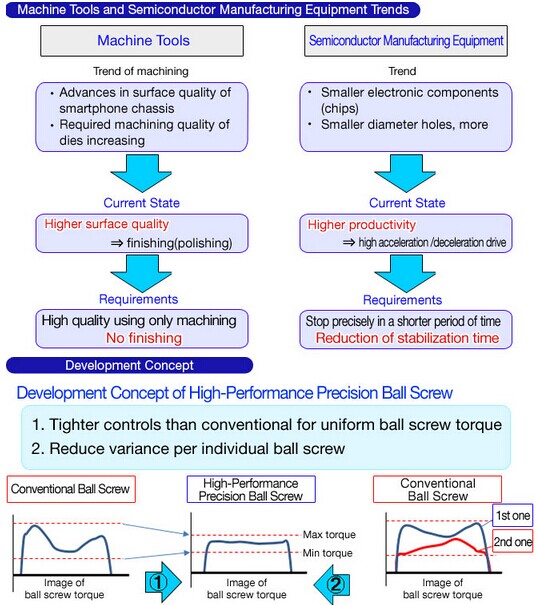

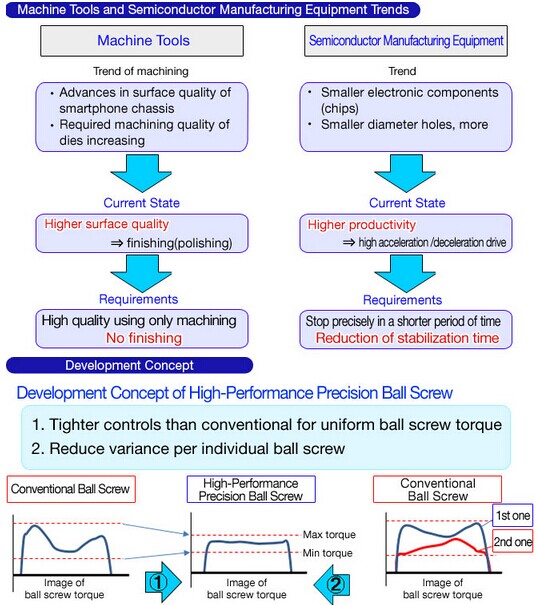

Development Background

In recent years, there has been a rise in the demand for less motion error in ball screws in order to improve the surface quality of machined components as a result of the increase in the precision of machine tools, such as 5-axis machine tools, as well as an increase in the surface quality of die-fabricated parts.

Likewise, for semiconductor manufacturing equipment, there has been a rise in the demand for higher productivity of printed circuit boards by increasing the fabrication capacity per unit time due to the miniaturization of electronic components such as those used in smart phones.

In response to these demands, and driven by advances in its production technology, NSK has released a new high-performance precision ball screw.

Product Features

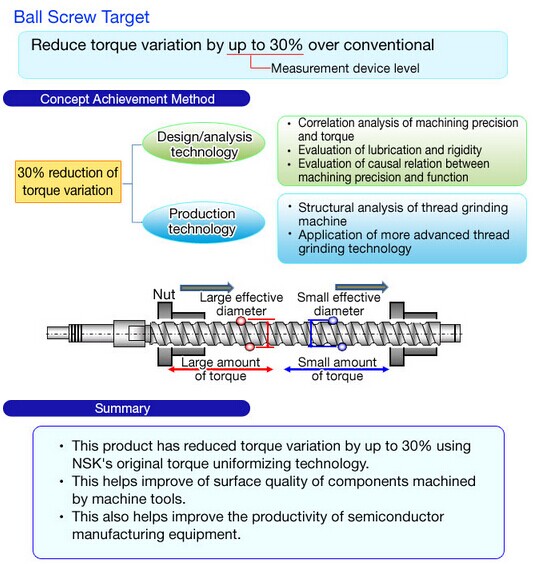

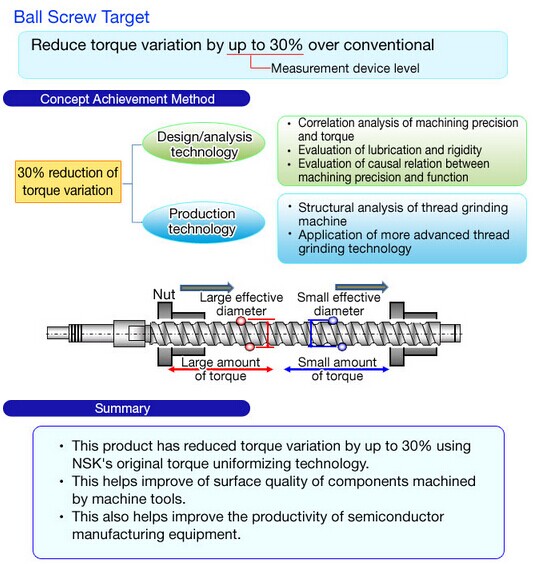

30% reduction in ball screw torque variance

Thanks to NSK's proprietary ball screw thread groove machining technology, torque fluctuations caused by nut position differences in the ball screw have been stabilized.

Product value improvement of customer's products

1. Significant improvement in the motion control of machine tools

This new ball screw reduces the motion control error caused by nut position differences in the ball screw, which in turn makes it possible to improve the surface quality of parts fabricated by machine tools.

2. Reduce the variation of positioning settling time

Since the torque of this new ball screw is more stable, it will now take less time to stabilize positioning, which in turn makes it possible to improve the productivity of semiconductor manufacturing equipment.

Applications

Machine tools, semiconductor manufacturing equipment, medical devices, measurement devices, etc.

(NSK)

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.