Blade Dynamics develops, manufactures advanced wind turbine blades, soon part of GE

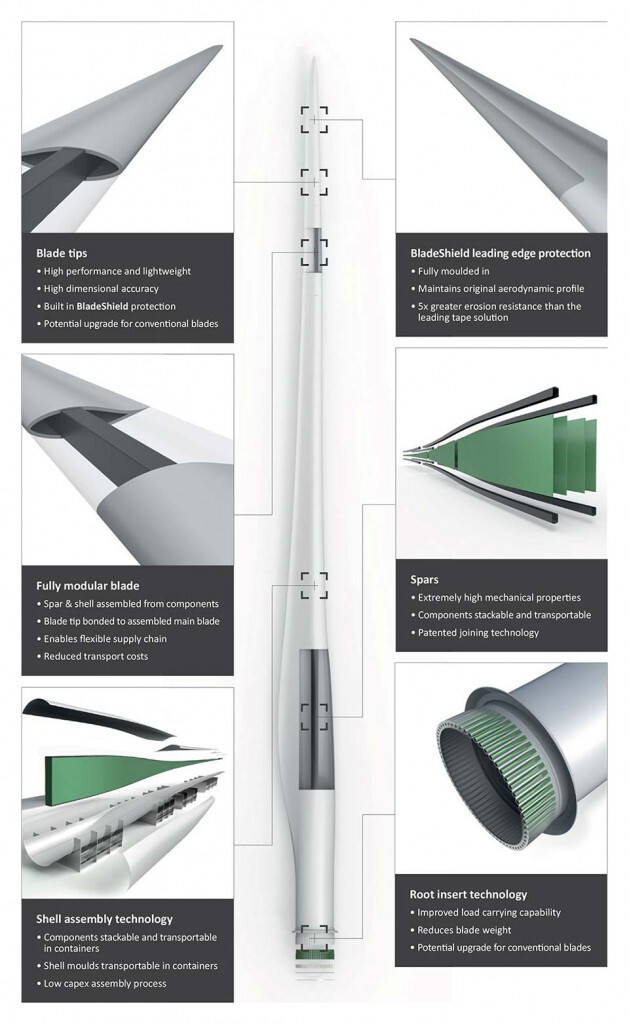

GE Wind recently announced that it purchased U.K. blade manufacturer Blade Dynamics. Demand for wind turbine blades exceeding 55m continues to increase and has driven segmented blade technology from a niche application to a commercial necessity. BD is the innovator behind a potentially disruptive modular blade concept that aims to reduce blade weight and increase reliability.Blade dynamics 2Onshore_KeyFeatures_new

The company’s engineering staff has patented a range of innovations for wind-turbine rotors. For example, GL has certified one BD blade as the lightest 49m blade in the world. The company says it is working on what could be the largest offshore turbine blades in the world.

The technology

Blade Dynamics says it has created is the most advanced blade platform available. Its high performance, reliability and cost-effectiveness enables the next generation of turbines for low wind areas, large transportable blades onshore, and ultra-large offshore turbines. Traditionally, cost-effectiveness, reliability and performance were mutually exclusive but the company says its innovation have brought all three together.

An example

The company’s leading edge protection for wind turbines blades is a critical technology area with a significant bearing on the cost of energy, especially offshore, where maintenance costs are high. It has been accepted in the past that blades are a wear component that will require replenished leading edge protection repeatedly during its operational life. However, BladeShield, the company’s leading edge protection is molded into the blade and therefore aerodynamically accurate to the designed airfoil.

The polymer protection membrane has been proven to have more than 500% longer protective life than polyurethane tapes in side by side testing of resistance to rain erosion after accelerated ultraviolet light exposure and salt water saturation. In addition, the “clean” molded airfoil profile eliminates the up-front AEP loss of applying leading edge protections.

GE Wind recently announced that it purchased U.K. blade manufacturer Blade Dynamics. Demand for wind turbine blades exceeding 55m continues to increase and has driven segmented blade technology from a niche application to a commercial necessity. BD is the innovator behind a potentially disruptive modular blade concept that aims to reduce blade weight and increase reliability.Blade dynamics 2Onshore_KeyFeatures_new

The company’s engineering staff has patented a range of innovations for wind-turbine rotors. For example, GL has certified one BD blade as the lightest 49m blade in the world. The company says it is working on what could be the largest offshore turbine blades in the world.

The technology

Blade Dynamics says it has created is the most advanced blade platform available. Its high performance, reliability and cost-effectiveness enables the next generation of turbines for low wind areas, large transportable blades onshore, and ultra-large offshore turbines. Traditionally, cost-effectiveness, reliability and performance were mutually exclusive but the company says its innovation have brought all three together.

An example

The company’s leading edge protection for wind turbines blades is a critical technology area with a significant bearing on the cost of energy, especially offshore, where maintenance costs are high. It has been accepted in the past that blades are a wear component that will require replenished leading edge protection repeatedly during its operational life. However, BladeShield, the company’s leading edge protection is molded into the blade and therefore aerodynamically accurate to the designed airfoil.

The polymer protection membrane has been proven to have more than 500% longer protective life than polyurethane tapes in side by side testing of resistance to rain erosion after accelerated ultraviolet light exposure and salt water saturation. In addition, the “clean” molded airfoil profile eliminates the up-front AEP loss of applying leading edge protections.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.