Igus receives 10,000th order from robotics company

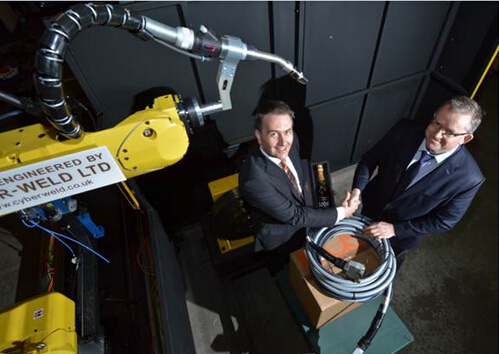

Igus director Justin Leonard presents Fraser Reid, managing director of Cyber-Weld, with the 10,000th readycable order

As Cyber-Weld reaches 10,000 orders for readycable products, igus outlines the advantages of using robotics in the welding process

Robotic welding systems have been widely used in large scale automated manufacturing facilities, particularly in the automotive industry, for a number of years.

Faced with cost pressures from their customers, small metalworking job shops are now starting to consider implementing automation.

When the operating costs of robotic welding are compared to manual welding the results are now clearly in favour of the robot. Additional benefits of automating are increased productivity, more consistent welded joints and improved quality.

Cyber-Weld, a UK-based provider of robotic welding solutions, provides a simple cost analysis to its potential customers.

Using manual welding, the overhead cost is around £35,000 a year for a single shift, with an average arc-on time of 25 per cent.

Arc time is the time interval during which an arc is maintained in the making of an arc weld.

The average robot arc-on time is 75 per cent, three times that of a manual welder, resulting in an additional 200 per cent production capability. With an entry level robot and operator costs of £17,500 the payback time is less than 12 months.

Potential users do have concerns, though. How easy are they to program? Where to find trained staff to operate them? How reliable are the robots?

When choosing a partner, reputation should always be the first consideration, says igus, adding that “a reliable partner must provide advice on which robot to select and be able to provide a full turn-key solution with support from the initial inquiry through to the installation”.

Prompt delivery, machine commissioning, employee training, trouble shooting, repair and offering regular system overhauls are other key factors. Look for a company that is a strategic partner for one or more of the leading robot manufacturers.

Cyber-Weld regularly uses igus as a supplier and partner for cable assemblies on their robotic welding machines for the same reasons and has bought over 100 readycable drive cables.

Cyber-Weld’s last purchase marked a milestone for igus; being the 10,000th order for the product series.

These highly flexible cables provide power and signals to the robotic head, grippers or other attachments and are usually mounted externally to the robotic arm. Particularly on a 6-axis robot, this cable is subject to a great deal of rigorous movement, which can lead to premature failure if incorrectly specified.

“We expect the cables to outlive the mission time of the installed robotic system, which is approximately 10 to 15 years,” says Mike Jones, general manager, of Cyber-Weld. “Igus is always helpful and is happy to come onsite to look at our requirements, which is a big plus factor for us. A local supplier with a good reputation, igus also helps us shorten our lead-times.”

The readycable assembled drive cables series has bending radius from 7.5 x od [outer diameter]. Harnessed cables are tested in igus e-chain cable carriers through many millions of cycles.

There is a choice of servo cables, signal cables and feeder cables with a total of seven cable quality levels for the same electrical requirement, offering an affordable and durable solution for all applications.

The readycable assembled drive cables also have a number of certifications and regulatory conformities including UL, CSA, CE Desina. These extremely reliable cables are designed for high stress applications and are also available with flame and oil resistance.

It is no contradiction to say that good cables cost less. Fast delivery throughout the world is a significant purchase criterion, and igus can provide that with a presence and stock in more than 40 countries. This saves time, money, part storage capacity and is applicable to 1,040 igus cable types, which can be ordered without any minimum quantity purchases or surcharges.

In the igus test facility in Cologne, numerous parallel tests are conducted under the most severe conditions. Presently more than 2 billion double strokes and 1.4 million electrical tests are carried out per year, with the test results stored in an extensive data-base, providing precise and reliable data about actual service life.

The test data for e-chains, cables, and also for ready-assembled systems, are so extensive that igus has secured a functional guarantee for its variety of e-chain systems based on the particular application.

The igus reputation appreciated by Cyber-Weld comes from this extensive testing and more than 25-years of industry experience in continuous-flex cable. Further information and the on-line readycable product finder can be found on the igus website, including searches by machine producer and cable type.

Igus is based in Northampton in the UK, and has its global headquarters in Cologne, Germany. The company claims to be the largest producer of injection moulded polymer bearings and reinforced plastic cable carriers in the world.

Product lines include e-chain cable carriers, chainflex continuous-flex cables, iglidur plastic plain bearings, igubal spherical bearings, drylin linear bearings and guide systems. The company has 26 subsidiaries across 31 countries and employs more than 2,150 people worldwide.

Igus director Justin Leonard presents Fraser Reid, managing director of Cyber-Weld, with the 10,000th readycable order

As Cyber-Weld reaches 10,000 orders for readycable products, igus outlines the advantages of using robotics in the welding process

Robotic welding systems have been widely used in large scale automated manufacturing facilities, particularly in the automotive industry, for a number of years.

Faced with cost pressures from their customers, small metalworking job shops are now starting to consider implementing automation.

When the operating costs of robotic welding are compared to manual welding the results are now clearly in favour of the robot. Additional benefits of automating are increased productivity, more consistent welded joints and improved quality.

Cyber-Weld, a UK-based provider of robotic welding solutions, provides a simple cost analysis to its potential customers.

Using manual welding, the overhead cost is around £35,000 a year for a single shift, with an average arc-on time of 25 per cent.

Arc time is the time interval during which an arc is maintained in the making of an arc weld.

The average robot arc-on time is 75 per cent, three times that of a manual welder, resulting in an additional 200 per cent production capability. With an entry level robot and operator costs of £17,500 the payback time is less than 12 months.

Potential users do have concerns, though. How easy are they to program? Where to find trained staff to operate them? How reliable are the robots?

When choosing a partner, reputation should always be the first consideration, says igus, adding that “a reliable partner must provide advice on which robot to select and be able to provide a full turn-key solution with support from the initial inquiry through to the installation”.

Prompt delivery, machine commissioning, employee training, trouble shooting, repair and offering regular system overhauls are other key factors. Look for a company that is a strategic partner for one or more of the leading robot manufacturers.

Cyber-Weld regularly uses igus as a supplier and partner for cable assemblies on their robotic welding machines for the same reasons and has bought over 100 readycable drive cables.

Cyber-Weld’s last purchase marked a milestone for igus; being the 10,000th order for the product series.

These highly flexible cables provide power and signals to the robotic head, grippers or other attachments and are usually mounted externally to the robotic arm. Particularly on a 6-axis robot, this cable is subject to a great deal of rigorous movement, which can lead to premature failure if incorrectly specified.

“We expect the cables to outlive the mission time of the installed robotic system, which is approximately 10 to 15 years,” says Mike Jones, general manager, of Cyber-Weld. “Igus is always helpful and is happy to come onsite to look at our requirements, which is a big plus factor for us. A local supplier with a good reputation, igus also helps us shorten our lead-times.”

The readycable assembled drive cables series has bending radius from 7.5 x od [outer diameter]. Harnessed cables are tested in igus e-chain cable carriers through many millions of cycles.

There is a choice of servo cables, signal cables and feeder cables with a total of seven cable quality levels for the same electrical requirement, offering an affordable and durable solution for all applications.

The readycable assembled drive cables also have a number of certifications and regulatory conformities including UL, CSA, CE Desina. These extremely reliable cables are designed for high stress applications and are also available with flame and oil resistance.

It is no contradiction to say that good cables cost less. Fast delivery throughout the world is a significant purchase criterion, and igus can provide that with a presence and stock in more than 40 countries. This saves time, money, part storage capacity and is applicable to 1,040 igus cable types, which can be ordered without any minimum quantity purchases or surcharges.

In the igus test facility in Cologne, numerous parallel tests are conducted under the most severe conditions. Presently more than 2 billion double strokes and 1.4 million electrical tests are carried out per year, with the test results stored in an extensive data-base, providing precise and reliable data about actual service life.

The test data for e-chains, cables, and also for ready-assembled systems, are so extensive that igus has secured a functional guarantee for its variety of e-chain systems based on the particular application.

The igus reputation appreciated by Cyber-Weld comes from this extensive testing and more than 25-years of industry experience in continuous-flex cable. Further information and the on-line readycable product finder can be found on the igus website, including searches by machine producer and cable type.

Igus is based in Northampton in the UK, and has its global headquarters in Cologne, Germany. The company claims to be the largest producer of injection moulded polymer bearings and reinforced plastic cable carriers in the world.

Product lines include e-chain cable carriers, chainflex continuous-flex cables, iglidur plastic plain bearings, igubal spherical bearings, drylin linear bearings and guide systems. The company has 26 subsidiaries across 31 countries and employs more than 2,150 people worldwide.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.