Voith BHS AeroMaXX for turbo parallel-shaft gears unveiled

• Voith BHS AeroMaXX increases the efficiency of turbo parallel-shaft gear units by up to 0.5%

• Oil consumption of the gear unit reduced by more than 30%

• The 36-month warranty is manufacturer-independent and includes retrofits

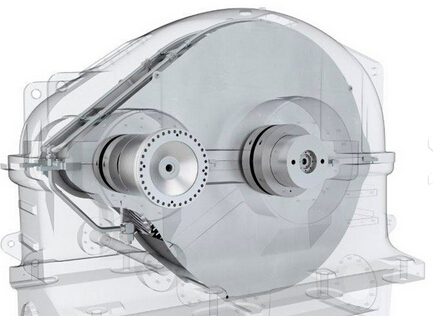

Voith unveiled the new BHS AeroMaXX technology for turbo parallel-shaft gear units at Power-Gen Europe 2016 in Milan from 21 to 23 June. The inner housing and optimised sleeve bearings reduce power loss and oil consumption by 30% or more.

The solution has a passive-mechanical character and does not require any additional accessories. Operators profit from identical design standards, unchanged overall operating behaviour and maximum reliability. Voith emphasises this with a 36-month warranty period – in both new systems and retrofits. The technology is manufacturer-independent and available immediately.

Due to the high pitch line velocities of up to 200 m/s, oil swirling and oil squeezing in the gear mesh account for a substantial part of the power loss of high-speed turbo gear units. The BHS AeroMaXX technology reduces these losses by separating lubrication and cooling.

An inner housing in the direct vicinity of the gear set absorbs heat and dissipates it into the bottom area on the external surface on the inner housing via cooling oil. This means that a substantially smaller volume of oil is required for the actual lubrication of the teeth contact surfaces, while the swirling oil/air mixture itself is minimised.

In addition to the inner housing, the technology also includes new BHS EcoMax sleeve bearings on the pinion shaft. These hydrodynamic bearings are optimised specifically for the application, and guarantee high energy efficiency along with significant oil savings.

By combining the inner housing and the specifically-designed bearings, BHS AeroMaXX increases the gear unit efficiency by up to 0.5%. At the same time, oil consumption is reduced by at least 30%. Since only passive mechanical elements are used, the improvements can be achieved without any additional accessories or components such as pumps or seals.

The overall operating behaviour, design standards and dimensions of the gear unit also are not affected by this technology. Related costs for a system operator are amortised by the energy savings alone within one to two years.

• Voith BHS AeroMaXX increases the efficiency of turbo parallel-shaft gear units by up to 0.5%

• Oil consumption of the gear unit reduced by more than 30%

• The 36-month warranty is manufacturer-independent and includes retrofits

Voith unveiled the new BHS AeroMaXX technology for turbo parallel-shaft gear units at Power-Gen Europe 2016 in Milan from 21 to 23 June. The inner housing and optimised sleeve bearings reduce power loss and oil consumption by 30% or more.

The solution has a passive-mechanical character and does not require any additional accessories. Operators profit from identical design standards, unchanged overall operating behaviour and maximum reliability. Voith emphasises this with a 36-month warranty period – in both new systems and retrofits. The technology is manufacturer-independent and available immediately.

Due to the high pitch line velocities of up to 200 m/s, oil swirling and oil squeezing in the gear mesh account for a substantial part of the power loss of high-speed turbo gear units. The BHS AeroMaXX technology reduces these losses by separating lubrication and cooling.

An inner housing in the direct vicinity of the gear set absorbs heat and dissipates it into the bottom area on the external surface on the inner housing via cooling oil. This means that a substantially smaller volume of oil is required for the actual lubrication of the teeth contact surfaces, while the swirling oil/air mixture itself is minimised.

In addition to the inner housing, the technology also includes new BHS EcoMax sleeve bearings on the pinion shaft. These hydrodynamic bearings are optimised specifically for the application, and guarantee high energy efficiency along with significant oil savings.

By combining the inner housing and the specifically-designed bearings, BHS AeroMaXX increases the gear unit efficiency by up to 0.5%. At the same time, oil consumption is reduced by at least 30%. Since only passive mechanical elements are used, the improvements can be achieved without any additional accessories or components such as pumps or seals.

The overall operating behaviour, design standards and dimensions of the gear unit also are not affected by this technology. Related costs for a system operator are amortised by the energy savings alone within one to two years.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Siemens Expands Portfolio with 8 MW Offshore Wind Turbine

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.