New Wärtsilä Sea-Master system uses digital technology to maximise uptime and reduce lifecycle costs of vessel shaft lines

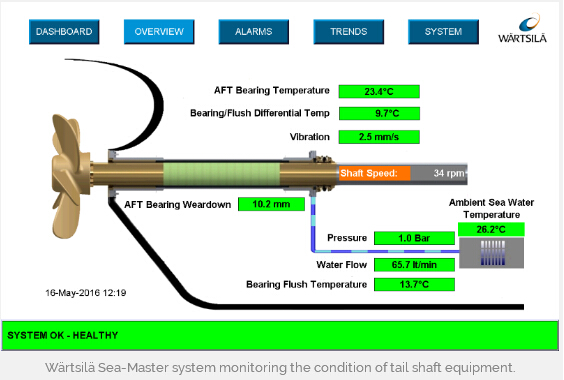

Wärtsilä Sea-Master system monitoring the condition of tail shaft equipment.

Wärtsilä Sea-Master also provides early warning for the detection of rising failure issues with system alarms for critical path components, including bearing temperatures and lubrication rates. The system is approved by relevant classification societies and is available for all vessel segments and ship types as well as for new build and retrofit applications.

“We used our existing condition monitoring technology to develop this new system and service, which applies proven data analysis methodology to deliver not only information but careful expert analysis and performance-enhancing recommendations as well. Our customers get a window into the operational health of their tail shaft and gain knowledge about, for instance, the wear rates of the equipment. This allows for more accurate maintenance planning and reduces unforeseen risks,” says Matthew Bignell, Sales Development Manager, Wärtsilä Seals & Bearings.

Certified data for tail shaft extension program approvals

For water-lubricated systems, the tail shaft of a vessel is typically removed in dry dock and inspected by a classification society in every five years. By capturing real-time data with trending, Wärtsilä Sea-Master allows vessel operators to provide reliable information about the condition of the tail shaft for classification society surveyors without having to withdraw the tail shaft extending the interval between removals and thereby reducing unnecessary downtime.

This versatile system has already sparked the interest of many marine customers. Pilot vessels that feature Wärtsilä Sea-Master are already in operation, and a number of retrofit programs will begin in September 2016.

“Our goal is to help our customers optimise their operations by providing safe, reliable and environmentally sound solutions that ensure the health of their equipment. This goal also steers our product development and digital initiatives. Wärtsilä Sea-Master is a good example of the advances offered by digitalisation to the maintenance of propulsion technology,” Matthew Bignell says.

Wärtsilä Sea-Master system monitoring the condition of tail shaft equipment.

Wärtsilä Sea-Master also provides early warning for the detection of rising failure issues with system alarms for critical path components, including bearing temperatures and lubrication rates. The system is approved by relevant classification societies and is available for all vessel segments and ship types as well as for new build and retrofit applications.

“We used our existing condition monitoring technology to develop this new system and service, which applies proven data analysis methodology to deliver not only information but careful expert analysis and performance-enhancing recommendations as well. Our customers get a window into the operational health of their tail shaft and gain knowledge about, for instance, the wear rates of the equipment. This allows for more accurate maintenance planning and reduces unforeseen risks,” says Matthew Bignell, Sales Development Manager, Wärtsilä Seals & Bearings.

Certified data for tail shaft extension program approvals

For water-lubricated systems, the tail shaft of a vessel is typically removed in dry dock and inspected by a classification society in every five years. By capturing real-time data with trending, Wärtsilä Sea-Master allows vessel operators to provide reliable information about the condition of the tail shaft for classification society surveyors without having to withdraw the tail shaft extending the interval between removals and thereby reducing unnecessary downtime.

This versatile system has already sparked the interest of many marine customers. Pilot vessels that feature Wärtsilä Sea-Master are already in operation, and a number of retrofit programs will begin in September 2016.

“Our goal is to help our customers optimise their operations by providing safe, reliable and environmentally sound solutions that ensure the health of their equipment. This goal also steers our product development and digital initiatives. Wärtsilä Sea-Master is a good example of the advances offered by digitalisation to the maintenance of propulsion technology,” Matthew Bignell says.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ABB appoints Guido Jouret as Chief Digital Officer

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.