New crankshaft microfinishing possibilities opened up

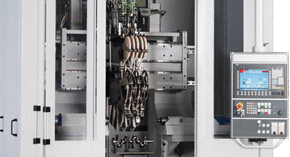

German high-precision machine tool manufacturer Thielenhaus Microfinish said it is now capable of machining crankshafts for engines with three to six cylinders, in some cases even without major retooling via the use of its CrankStar machine.

In addition to centre and pin bearings and thrust faces, the CrankStar can finish oil seal diameters and deburr bores in the flange. Thrust face machining occurs via a special unit while the workpiece is oscillated.

Even with vertical machine concepts, the CrankStar comes with up to 33 per cent longer intervals between tool changes than the industry standard, featuring a tape capacity of 300+ metres.

The vertical solution allows a quick belt change from the front of the machine, without requiring the withdrawal of an entire tool carrier package.

In addition to the conventional hard or soft shoes, Thielenhaus is developing a shoe that uses a kind of belt system to adapt to the component’s size.

With the DiaFlex technology, crankshafts with the same bearing widths but different diameters can be machined without swapping the shoes.

In practice, it often happens that, due to higher torques in three- or four-cylinder motors, a few millimetres more of bearing diameter are needed with the same motor concept and gauge.

The DiaFlex shoe adapts to the respective diameter and can compensate for differences of up to 15 mm without changing shoes.

German high-precision machine tool manufacturer Thielenhaus Microfinish said it is now capable of machining crankshafts for engines with three to six cylinders, in some cases even without major retooling via the use of its CrankStar machine.

In addition to centre and pin bearings and thrust faces, the CrankStar can finish oil seal diameters and deburr bores in the flange. Thrust face machining occurs via a special unit while the workpiece is oscillated.

Even with vertical machine concepts, the CrankStar comes with up to 33 per cent longer intervals between tool changes than the industry standard, featuring a tape capacity of 300+ metres.

The vertical solution allows a quick belt change from the front of the machine, without requiring the withdrawal of an entire tool carrier package.

In addition to the conventional hard or soft shoes, Thielenhaus is developing a shoe that uses a kind of belt system to adapt to the component’s size.

With the DiaFlex technology, crankshafts with the same bearing widths but different diameters can be machined without swapping the shoes.

In practice, it often happens that, due to higher torques in three- or four-cylinder motors, a few millimetres more of bearing diameter are needed with the same motor concept and gauge.

The DiaFlex shoe adapts to the respective diameter and can compensate for differences of up to 15 mm without changing shoes.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Aug 17 Bearing Steel Price in Different Regions of China

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.