NB's Advanced Machining Capabilities answers the High Accuracy needs for Spindle Products

NB spindle shafts complement an industry-leading line of bearings, bushings and related products. We offer engineering, manufacturing and overhaul of spindle units to provide a complete solution for general machinery, semiconductor and a diverse range of other applications. ISO 9001- and ISO 14001-registered facilities allow us to deliver outstanding quality control, even for high volume orders.

Keep reading to learn more about our spindle shaft manufacturing capabilities or contact our office directly to request a quote for your project.

Key Benefits At-a-Glance

NB’s experience in spindle shaft manufacturing and other precision machining dates back to 1939. In that time, we’ve developed a reputation for unsurpassed quality and innovation in everything we do. When you contact us for any spindle shaft engineering project, you are working with a company that’s dedicated to providing:

Flexible manufacturing options

including bearing case and spindle base design, complete unit engineering and overhauling of worn components

Precision machining capabilities

in our state-of-the-art, climate-controlled facilities designed to meet exceptionally high requirements for tolerance and overall quality control

Innovative surface treatments

including hard chroming and ceramic coatings for new components, as well as re-plating and grinding worn units to restore them

Our spindle manufacturing capabilities include BT, BBT, HSK inner tapers, gauge and bearing matching, thread grinding and more. We work with a wide range of standard materials, including high-carbon chromium bearing steel, Martensitic stainless steel, steel alloys and carbon steel for tools and machinery, aluminum chrome molybdenum steel and more.

Our facilities are equipped with CNC lathes, boring and milling machines, vertical machining centers, internal grinding machines and other machine tools. To discuss your specific requirements with one of our engineers, contact the NB office today by phone or email.

Total Manufacturing Solutions

NB is committed to providing total manufacturing solutions for clients in any industry. We’ll work with you every step of the way to deliver a product that meets your needs, offers excellent value for your budget and is turned around within a reasonable timeframe.

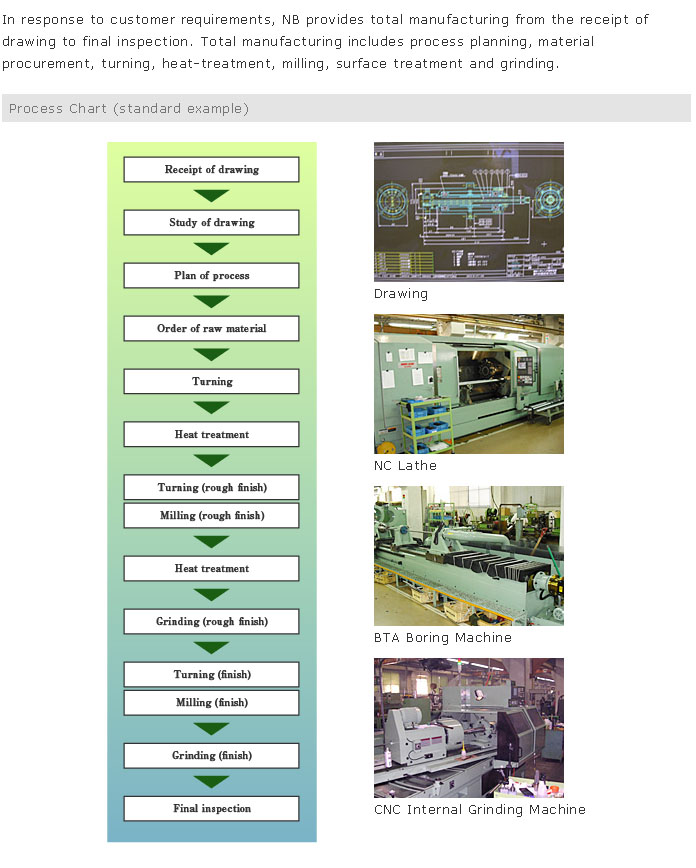

Upon receiving your drawings, we’ll review what’s required, order the necessary materials and develop a comprehensive plan for completing the project. From there, the spindle shaft production process involves multiple steps of turning, heat treatment, grinding and milling. It concludes with a final inspection to confirm we completed all work to the requested specifications.

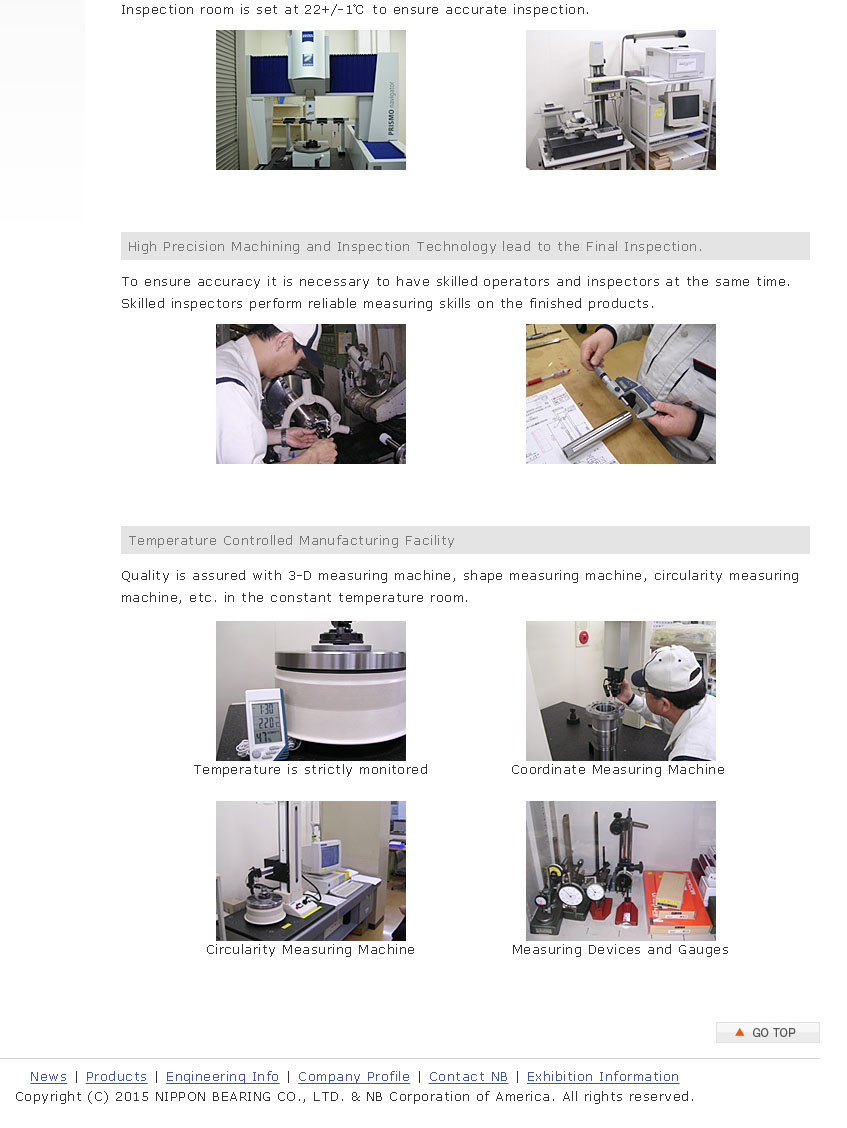

Our internal quality management processes ensure we complete orders of any size on time, on budget and to the highest standards of accuracy possible. Highly skilled technicians use sophisticated 3D measuring tools and work in a climate-controlled environment to deliver the best possible results for our clients. We ship the final product with a complete inspection sheet confirming your order meets your specifications.

Spindle

As a linear bearings manufacturer, NB is serving a variety of customers in many industries such as general machinery, semiconductor equipment, special purpose machines.

The NB SPINDLE is a further contribution to the industry. From parts to the spindle unit NB conducts integrated production through total manufacturing.

Please contact us for any requirement.

NB SPINDLE is backed by expertise gained from decades of experience in high accuracy machining.

ロールシャフトNB keeps supplying high quality products through skilled labor with time-nurtured skills, time-tested production process and technology, in addition to a help of the state-of-the art technology and equipment.

We have a belief that high processing technology is the key to customer-satisfaction.

NB spindle shafts complement an industry-leading line of bearings, bushings and related products. We offer engineering, manufacturing and overhaul of spindle units to provide a complete solution for general machinery, semiconductor and a diverse range of other applications. ISO 9001- and ISO 14001-registered facilities allow us to deliver outstanding quality control, even for high volume orders.

Keep reading to learn more about our spindle shaft manufacturing capabilities or contact our office directly to request a quote for your project.

Key Benefits At-a-Glance

NB’s experience in spindle shaft manufacturing and other precision machining dates back to 1939. In that time, we’ve developed a reputation for unsurpassed quality and innovation in everything we do. When you contact us for any spindle shaft engineering project, you are working with a company that’s dedicated to providing:

Flexible manufacturing options

including bearing case and spindle base design, complete unit engineering and overhauling of worn components

Precision machining capabilities

in our state-of-the-art, climate-controlled facilities designed to meet exceptionally high requirements for tolerance and overall quality control

Innovative surface treatments

including hard chroming and ceramic coatings for new components, as well as re-plating and grinding worn units to restore them

Our spindle manufacturing capabilities include BT, BBT, HSK inner tapers, gauge and bearing matching, thread grinding and more. We work with a wide range of standard materials, including high-carbon chromium bearing steel, Martensitic stainless steel, steel alloys and carbon steel for tools and machinery, aluminum chrome molybdenum steel and more.

Our facilities are equipped with CNC lathes, boring and milling machines, vertical machining centers, internal grinding machines and other machine tools. To discuss your specific requirements with one of our engineers, contact the NB office today by phone or email.

Total Manufacturing Solutions

NB is committed to providing total manufacturing solutions for clients in any industry. We’ll work with you every step of the way to deliver a product that meets your needs, offers excellent value for your budget and is turned around within a reasonable timeframe.

Upon receiving your drawings, we’ll review what’s required, order the necessary materials and develop a comprehensive plan for completing the project. From there, the spindle shaft production process involves multiple steps of turning, heat treatment, grinding and milling. It concludes with a final inspection to confirm we completed all work to the requested specifications.

Our internal quality management processes ensure we complete orders of any size on time, on budget and to the highest standards of accuracy possible. Highly skilled technicians use sophisticated 3D measuring tools and work in a climate-controlled environment to deliver the best possible results for our clients. We ship the final product with a complete inspection sheet confirming your order meets your specifications.

Spindle

As a linear bearings manufacturer, NB is serving a variety of customers in many industries such as general machinery, semiconductor equipment, special purpose machines.

The NB SPINDLE is a further contribution to the industry. From parts to the spindle unit NB conducts integrated production through total manufacturing.

Please contact us for any requirement.

NB SPINDLE is backed by expertise gained from decades of experience in high accuracy machining.

ロールシャフトNB keeps supplying high quality products through skilled labor with time-nurtured skills, time-tested production process and technology, in addition to a help of the state-of-the art technology and equipment.

We have a belief that high processing technology is the key to customer-satisfaction.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Advanced Materials Development Corp. Offers New Material Options for Automotive Components

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.