Development of “ULTAGE Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles”

NTN Corporation (hereafter, NTN) has developed the “ULTAGE* Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles” (internal diameter φ10 mm to φ50 mm) that deliver low vibrations and long operating life of small spindles (small main shafts) used for machining small parts and precision machining.

In addition to the basic performance of “high-speed, high-rigidity and high-precision” required for “mother machines,” various models of machine tools are constantly being developed in recent years that include new functions and concepts such as “smaller size,” “high power output” and “more environmentally friendly” for energy and space saving. Of these, development of low-cost and space-saving smaller machine tools is increasing in emerging countries, and there is also an increase in precision machining for machining small products, parts for medical equipment and other applications. With such industry trends, the demand for small spindle is growing.

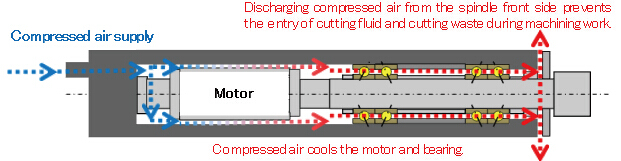

Small spindles often feature a structure that feeds compressed air inside for internal cooling and to prevent the intrusion of foreign matter from outside. For bearings filled with grease, some bearings do not come with seals installed, causing the grease may leak from the bearing due to the compressed air, which results in a shorter operating life. Sealed bearings are effective for limiting the amount of grease leaking, however this reduces the amount of compressed air flowing through the spindle. This causes issues related to cooling performance and affects how much foreign matter can be prevented from entering. The newly developed “ULTAGE Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles” uses newly designed seal that retains grease within the bearing without affecting cooling or dust prevention performance using compressed air. The seal also improves the amount of grease inside and the flow of compressed air. The grease filling position and amount have also been improved to ensure a longer operating life.

Small spindles also need to have “low vibrations” as they are often used to improve the external appearance of products, such as enhancing machining precision or providing a fine finish on machined surfaces. The developed product is made with machining method that enhances the precision of the bearing raceway surface, to reduce vibrations by approximately 50% compared to conventional products.

NTN will exhibit the developed product at “The 28th Japan International Machine Tool Fair (JIMTOF2016)” to be held at Tokyo Big Sight from November 17 to 22, and will propose it to various machine tool manufacturers and spindle manufacturers for the development of new models.

* ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the “ULTIMATE” performance on any type of “STAGE.”

Features

(1) Long operating life higher sealing performance than NTN's conventional products

High grease retention

(4 times or more than NTN's conventional products)

High-speed durability of more than 6,000 hours

(10 times or more than NTN's conventional products)

(2) Low vibration 50% reduction compared to NTN's conventional products

(when supplied with grease lubrication, fixed-position preload, bearing internal diameter 10mm rotational speed 60000min-1, compressed air within main shaft (0.3 MPa, 30 NL/min))

Applications

Small spindles for machine tools, etc.

NTN Corporation (hereafter, NTN) has developed the “ULTAGE* Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles” (internal diameter φ10 mm to φ50 mm) that deliver low vibrations and long operating life of small spindles (small main shafts) used for machining small parts and precision machining.

In addition to the basic performance of “high-speed, high-rigidity and high-precision” required for “mother machines,” various models of machine tools are constantly being developed in recent years that include new functions and concepts such as “smaller size,” “high power output” and “more environmentally friendly” for energy and space saving. Of these, development of low-cost and space-saving smaller machine tools is increasing in emerging countries, and there is also an increase in precision machining for machining small products, parts for medical equipment and other applications. With such industry trends, the demand for small spindle is growing.

Small spindles often feature a structure that feeds compressed air inside for internal cooling and to prevent the intrusion of foreign matter from outside. For bearings filled with grease, some bearings do not come with seals installed, causing the grease may leak from the bearing due to the compressed air, which results in a shorter operating life. Sealed bearings are effective for limiting the amount of grease leaking, however this reduces the amount of compressed air flowing through the spindle. This causes issues related to cooling performance and affects how much foreign matter can be prevented from entering. The newly developed “ULTAGE Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles” uses newly designed seal that retains grease within the bearing without affecting cooling or dust prevention performance using compressed air. The seal also improves the amount of grease inside and the flow of compressed air. The grease filling position and amount have also been improved to ensure a longer operating life.

Small spindles also need to have “low vibrations” as they are often used to improve the external appearance of products, such as enhancing machining precision or providing a fine finish on machined surfaces. The developed product is made with machining method that enhances the precision of the bearing raceway surface, to reduce vibrations by approximately 50% compared to conventional products.

NTN will exhibit the developed product at “The 28th Japan International Machine Tool Fair (JIMTOF2016)” to be held at Tokyo Big Sight from November 17 to 22, and will propose it to various machine tool manufacturers and spindle manufacturers for the development of new models.

* ULTAGE is the name for NTN's new generation of the world's highest standard of bearing series, and expresses the “ULTIMATE” performance on any type of “STAGE.”

Features

(1) Long operating life higher sealing performance than NTN's conventional products

High grease retention

(4 times or more than NTN's conventional products)

High-speed durability of more than 6,000 hours

(10 times or more than NTN's conventional products)

(2) Low vibration 50% reduction compared to NTN's conventional products

(when supplied with grease lubrication, fixed-position preload, bearing internal diameter 10mm rotational speed 60000min-1, compressed air within main shaft (0.3 MPa, 30 NL/min))

Applications

Small spindles for machine tools, etc.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Miki Pulley Micro Clutches Designed for Compact Precision Applications

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.