Hannover Fair Preview: Voith

From April 24-28, visitors of the Voith stand (Hall 23, Booth B39) at the Hannover Messe will experience live how plant operators can save up to 70 percent of energy cost in the future, while simultaneously increasing productivity. Voith will be presenting its innovative hydraulic systems and products for control machines and plants under the motto "Progressive Hydraulic Solutions.” The spotlight will focus on the linear drives CLDP and HPD as well as Voith servo pumps.

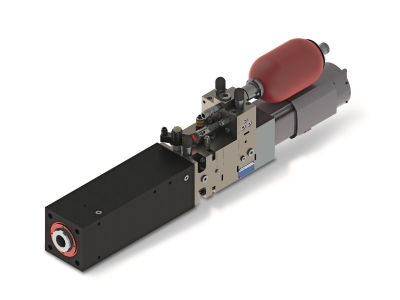

Reduce Energy Costs by up to 50 percent – the Self-Contained CLDP Servo Drive from Voith The Voith CLDP servo drive (Closed Loop Differential Pump) can be used for all direct linear motions, especially when dynamic response, reproducibility and reliability are needed. Enhanced productivity, high energy efficiency, full programmable position or force control and longer lifetime of the drive, are attractive features for plant operators. They are almost wear-free and have an unrestricted overload protection. Unlike electromechanical drives this self-contained servo drive offers customers the full range of benefits of a hydraulic systems solution.

The combination of a proven hydraulic system with an efficient servo drive in one system – Hybrid Servo Punch Drive HPD

Voith hydraulic punching drives are complete systems with a modular design. Voith offers a "best-fit" drive system for every class of punching machine. The new HPD hybrid servo punch fits into this concept. It requires mechanically the same assembly surface as all Voith punching drives. Migration to HPD will require little or no change to the machine frame. The same applies to the electrical interface. Our HS4 controller version for HPD provides the same hardware interface and parameter structure as all HS4 versions of other Voith punch drives. The functional principle of HPD is based on a closed circuit hydraulic system. The pump is directly connected to the cylinder and operates as a hydrostatic transmission. In contrast to mechanical transmissions, the hydraulic transmissions and the linear cylinders are almost wear-free and extremely robust.

Maximum Productivity with Energy Savings of up to 70 Percent – The Voith Servo Pump

The future of hydraulics has arrived with servo pumps from Voith. Hydraulic applications with high demands on control technology are subject to greatly fluctuating stresses during operation. To ensure cost-effective operation even under these conditions, the Voith servo pump adjusts to the power actually needed over varying volume flows and motor speeds. This provides clear advantages over conventional systems, particularly in the part load range, with a uniformly high volume flow that is needed only rarely within an operating cycle. Optimized operation reduces energy consumption by up to 70 percent and the total cost of ownership (TCO) of the entire hydraulic system by up to 35 percent. In this way, it is usually amortized within one to two years.

From April 24-28, visitors of the Voith stand (Hall 23, Booth B39) at the Hannover Messe will experience live how plant operators can save up to 70 percent of energy cost in the future, while simultaneously increasing productivity. Voith will be presenting its innovative hydraulic systems and products for control machines and plants under the motto "Progressive Hydraulic Solutions.” The spotlight will focus on the linear drives CLDP and HPD as well as Voith servo pumps.

Reduce Energy Costs by up to 50 percent – the Self-Contained CLDP Servo Drive from Voith The Voith CLDP servo drive (Closed Loop Differential Pump) can be used for all direct linear motions, especially when dynamic response, reproducibility and reliability are needed. Enhanced productivity, high energy efficiency, full programmable position or force control and longer lifetime of the drive, are attractive features for plant operators. They are almost wear-free and have an unrestricted overload protection. Unlike electromechanical drives this self-contained servo drive offers customers the full range of benefits of a hydraulic systems solution.

The combination of a proven hydraulic system with an efficient servo drive in one system – Hybrid Servo Punch Drive HPD

Voith hydraulic punching drives are complete systems with a modular design. Voith offers a "best-fit" drive system for every class of punching machine. The new HPD hybrid servo punch fits into this concept. It requires mechanically the same assembly surface as all Voith punching drives. Migration to HPD will require little or no change to the machine frame. The same applies to the electrical interface. Our HS4 controller version for HPD provides the same hardware interface and parameter structure as all HS4 versions of other Voith punch drives. The functional principle of HPD is based on a closed circuit hydraulic system. The pump is directly connected to the cylinder and operates as a hydrostatic transmission. In contrast to mechanical transmissions, the hydraulic transmissions and the linear cylinders are almost wear-free and extremely robust.

Maximum Productivity with Energy Savings of up to 70 Percent – The Voith Servo Pump

The future of hydraulics has arrived with servo pumps from Voith. Hydraulic applications with high demands on control technology are subject to greatly fluctuating stresses during operation. To ensure cost-effective operation even under these conditions, the Voith servo pump adjusts to the power actually needed over varying volume flows and motor speeds. This provides clear advantages over conventional systems, particularly in the part load range, with a uniformly high volume flow that is needed only rarely within an operating cycle. Optimized operation reduces energy consumption by up to 70 percent and the total cost of ownership (TCO) of the entire hydraulic system by up to 35 percent. In this way, it is usually amortized within one to two years.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Nexen Introduces Pre-configured Geared Bearing Solution – Zero Backlash Gear and High Capacity Bearing in One Package

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.