Update on what causes micro cracks that eventually fail turbine bearings

One big root cause of gearbox failures has led scientists and engineers to look more closely at the white etched areas that form just under the surface of failed bearing races. What initiates these tiny cracks that eventually cause turbine shutdowns is still something of a mystery, but it is slowly giving way with close scrutiny.

For example, the slipping-versus-roll ratio of bearing elements is now considered a prime driver for white etched cracks. And researchers are able to reproduce the cracks on samples with equipment in a lab. Those are just a couple ideas presented by Dr. Aaron Greco, Principal Materials Scientist, and post-doctoral student Ben Gould, at the recent Drivetrain Reliability Collaborative presented by NREL.

The Argonne National Lab researcher acknowledged collaboration with Afton Chemical and SKF and had more to say on this multi-lab effort to understand the white etching crack or axial crack issue. The term white etching refers to small and early cracking that is some form of microstructural alteration to the material field – a harder more brittle phase of steel that surrounds the cracking.

Its causes are more than just load. “I think the initial gut reaction is to say ‘well, we’re just overloading the system,’ and that’s the cause but there are other issues that might be inducing the system,” said Greco.

Greco said he sees most damage on the high-speed and intermediate speed shafts. When a failure occurs in those locations, it can typically involve an up-tower bearing replacement. But when not caught early enough, it causes other issues such as bearings that deteriorate and put more wear on the system.

There are many theories for the causes. “We’ve characterized them into mechanical conditions, which include loads, slips, frictional energy, and then others such as water corrosion, stray currents, and lubricant formulations. So these are all possible pathways that may cause white etched cracks. With the new test equipment, we can probe all of these different conditions. The ones of most interest are related to loads and slips and the contact severity,” he said.

There is a two-fold reason for developing a bench-top device, such as Greco’s bearing-material tester, the G2 machine that generates white etched cracks. “If you can replicate the failure in a controlled environment, you can understand the nobs to turn that cause.

bearings to fail, and better understand the root causes,” said Greco. The other reason: once you have a test method, you can start implementing or testing mitigation ideas, whether they involve materials, heat treatments, or lubricants. You can also start to validate the effectiveness of those mitigations.”

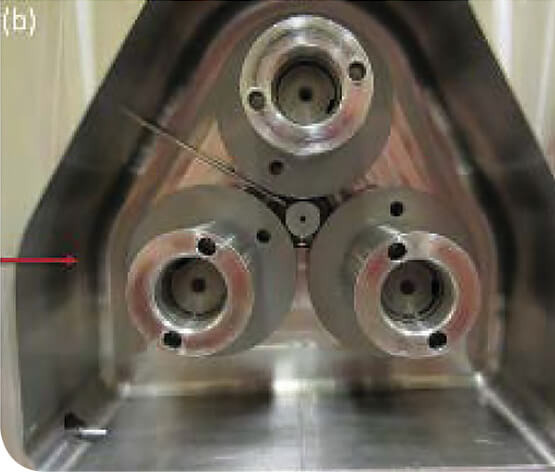

“The machine we use is called a three ring, contact roller, and its benefits include a simple design that generates a bearing contact in its simplest form — line contact between the roller and ring,” he added. It also allows wide control over the operating conditions so the researchers can change the slight roll ratio that’s induced in the contact, along with the load condition, temperature, and more.

“In the future, we will be working with the NREL staff to understand the real conditions occurring up tower in a wind turbine that might be leading to this failure, and to coordinate bench-top testing with up-tower testing,” he said.

One big root cause of gearbox failures has led scientists and engineers to look more closely at the white etched areas that form just under the surface of failed bearing races. What initiates these tiny cracks that eventually cause turbine shutdowns is still something of a mystery, but it is slowly giving way with close scrutiny.

For example, the slipping-versus-roll ratio of bearing elements is now considered a prime driver for white etched cracks. And researchers are able to reproduce the cracks on samples with equipment in a lab. Those are just a couple ideas presented by Dr. Aaron Greco, Principal Materials Scientist, and post-doctoral student Ben Gould, at the recent Drivetrain Reliability Collaborative presented by NREL.

The Argonne National Lab researcher acknowledged collaboration with Afton Chemical and SKF and had more to say on this multi-lab effort to understand the white etching crack or axial crack issue. The term white etching refers to small and early cracking that is some form of microstructural alteration to the material field – a harder more brittle phase of steel that surrounds the cracking.

Its causes are more than just load. “I think the initial gut reaction is to say ‘well, we’re just overloading the system,’ and that’s the cause but there are other issues that might be inducing the system,” said Greco.

Greco said he sees most damage on the high-speed and intermediate speed shafts. When a failure occurs in those locations, it can typically involve an up-tower bearing replacement. But when not caught early enough, it causes other issues such as bearings that deteriorate and put more wear on the system.

There are many theories for the causes. “We’ve characterized them into mechanical conditions, which include loads, slips, frictional energy, and then others such as water corrosion, stray currents, and lubricant formulations. So these are all possible pathways that may cause white etched cracks. With the new test equipment, we can probe all of these different conditions. The ones of most interest are related to loads and slips and the contact severity,” he said.

There is a two-fold reason for developing a bench-top device, such as Greco’s bearing-material tester, the G2 machine that generates white etched cracks. “If you can replicate the failure in a controlled environment, you can understand the nobs to turn that cause.

bearings to fail, and better understand the root causes,” said Greco. The other reason: once you have a test method, you can start implementing or testing mitigation ideas, whether they involve materials, heat treatments, or lubricants. You can also start to validate the effectiveness of those mitigations.”

“The machine we use is called a three ring, contact roller, and its benefits include a simple design that generates a bearing contact in its simplest form — line contact between the roller and ring,” he added. It also allows wide control over the operating conditions so the researchers can change the slight roll ratio that’s induced in the contact, along with the load condition, temperature, and more.

“In the future, we will be working with the NREL staff to understand the real conditions occurring up tower in a wind turbine that might be leading to this failure, and to coordinate bench-top testing with up-tower testing,” he said.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next What journal bearings may contribute to wind turbine gearboxes

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.