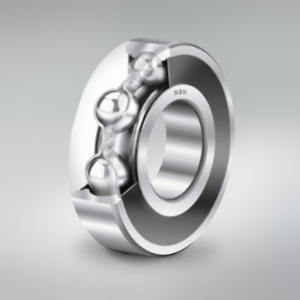

NSK launches low-friction ball bearings which ‘increase energy efficiency

NSK has launched low-friction ball bearings which it says increase energy efficiency and reduce operational noise in drive

systems.

Bearings of this type will also reduce heat generation, which in turn helps to extend service life, according to the

company.

Based on concepts such as optimised raceway geometry and special sealing concepts, NSK has developed several series of ball

bearings that offer significantly lower friction characteristics.

When looking to design energy-efficient drive systems, engineers should always ensure that they take the rolling bearings

into account.

The inherent friction which occurs from the motion of the rolling elements on raceways, as well as the contact of

conventional seals, can compromise drive efficiency.

As a result, NSK low-friction rolling bearings feature, among other attributes, proprietary geometry that reduces the

contact surface between the balls and raceways.

In addition, fibreglass-reinforced polyamide cages and high-performance lubricants can provide a significant contribution

to lowering frictional torque.

Production processes are another important factor in the creation of low-friction ball bearings. Here, any roughness in the

bearing raceway is likely to impair lubrication, increase running noise and generate greater friction.

This is why the raceways of NSK ball bearings undergo a bespoke honing process that is designed to deliver an extremely

smooth running surface.

With regard to seal technology, the non-contact labyrinth design developed and patented by NSK ensures efficient sealing

properties without increasing frictional torque or operating temperature.

This is vitally important in applications where any loss of performance is deemed to be particularly detrimental.

NSK ball bearings featuring non-contact labyrinth seals offer high-speed capability comparable with shielded bearings,

while at the same time providing important protection in harsh operating environments.

A variety of other sealing options are available depending on application requirements.

Market demand for low-friction ball bearings comes from sectors such domestic appliance, especially washing machines, where

manufacturers declaring a favourable efficiency class enjoy a distinct competitive edge.

The automotive industry is also making marked strides towards increasing the energy efficiency of its on-vehicle drive

mechanisms.

By way of example, the recent adoption of low-friction deep groove ball bearings at an NSK customer made it possible to

reduce frictional torque by 47 per cent in comparison with commonly-used standard ball bearings of the same type.

NSK has launched low-friction ball bearings which it says increase energy efficiency and reduce operational noise in drive

systems.

Bearings of this type will also reduce heat generation, which in turn helps to extend service life, according to the

company.

Based on concepts such as optimised raceway geometry and special sealing concepts, NSK has developed several series of ball

bearings that offer significantly lower friction characteristics.

When looking to design energy-efficient drive systems, engineers should always ensure that they take the rolling bearings

into account.

The inherent friction which occurs from the motion of the rolling elements on raceways, as well as the contact of

conventional seals, can compromise drive efficiency.

As a result, NSK low-friction rolling bearings feature, among other attributes, proprietary geometry that reduces the

contact surface between the balls and raceways.

In addition, fibreglass-reinforced polyamide cages and high-performance lubricants can provide a significant contribution

to lowering frictional torque.

Production processes are another important factor in the creation of low-friction ball bearings. Here, any roughness in the

bearing raceway is likely to impair lubrication, increase running noise and generate greater friction.

This is why the raceways of NSK ball bearings undergo a bespoke honing process that is designed to deliver an extremely

smooth running surface.

With regard to seal technology, the non-contact labyrinth design developed and patented by NSK ensures efficient sealing

properties without increasing frictional torque or operating temperature.

This is vitally important in applications where any loss of performance is deemed to be particularly detrimental.

NSK ball bearings featuring non-contact labyrinth seals offer high-speed capability comparable with shielded bearings,

while at the same time providing important protection in harsh operating environments.

A variety of other sealing options are available depending on application requirements.

Market demand for low-friction ball bearings comes from sectors such domestic appliance, especially washing machines, where

manufacturers declaring a favourable efficiency class enjoy a distinct competitive edge.

The automotive industry is also making marked strides towards increasing the energy efficiency of its on-vehicle drive

mechanisms.

By way of example, the recent adoption of low-friction deep groove ball bearings at an NSK customer made it possible to

reduce frictional torque by 47 per cent in comparison with commonly-used standard ball bearings of the same type.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next KISSsoft Includes Latest Bearing Data from Schaeffler

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.