Live Axle Bearing Replacement

Replacing wheel bearings on a vehicle with a live rear axle may not be one of the most frequent jobs you do, but it can be one of the most profitable. While the basics have not changed in more than 60 years, new seal materials and differential designs have added new wrinkles.

Bearings

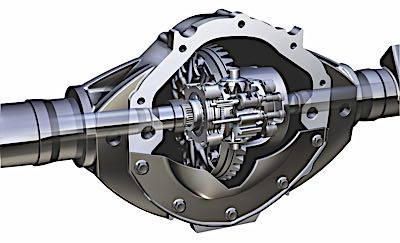

Replacing rear wheel bearings on a live axle rear suspension requires a few extra steps when compared to a unitized bearing. To remove the axle shaft, the differential must be accessed and the clips that hold the axle in the differential must be removed.

There are three bearing styles — Conrad, roller and ball. Most axles use these types of bearings in a cartridge-type arrangement. They are installed into the axle ends or pressed onto the shaft and possibly held in place with a pressed-on retainer. On some axles, the bore on the housing is tapered and the bearing will fit in only one direction. This is where measuring tools can save you time and maybe multiple part deliveries.

Some axles use a “floating” axle shaft design. This design takes the weight of the vehicle off the axle so all it has to do is transmit power. This allows the hub of the axle to carry a greater load. Some of these axles use tapered roller bearings. Another advantage of a floating axle is if the axle separates from the differential or flange, the wheel will not fall off the axle.

The most critical part of the disassembly is removing the bearing and retainer from the shaft without damaging the axle shaft or housing. Any damage to the surfaces that the seal or bearing ride on can cause a premature failure of the new bearing.

Another rookie mistake made by some technicians is installing the parts in the wrong order. It is not uncommon to press the new bearing onto the axle only to realize the flange plate was not installed.

Look at the differential cover before you quote the job. On snow-belt vehicles, the differential cover is prone to rust. Perforation does happen, but chances are prying on the weakened cover may distort it to the point that it will never seal. Replacement covers are readily available and very economical.

Seals

The main killer of solid axle wheel bearings is a failed seal. Most seals ride on the axle shaft, and they typically have a lip and a spring that holds the lip to the axle. When a seal is installed, take your time installing the axle. Splines can damage the seal and cause leaks.

The area on the axle shaft where the seal and bearings make contact is the most important. It must be free of rust and imperfections. Use only a fine-grade emery paper to clean the axle shaft between the flange and the worn area.

If the surface is grooved or damaged, the axle can be repaired with a sleeve on some applications. If not, the axle should be replaced. Another option for some applications is to install a replacement bearing that repositions the bearing and seal to ride on unworn surfaces.

Make sure the seal is installed in the correct position. A correctly installed bearing may extend out from the housing up to 1/4”. Some axles have small seals that must be positioned properly so pressures can be relieved and the lip can work.

Make sure the breathers on the axle are not clogged. The breather on some axles acts as a PCV valve to keep pressures within a certain range so the seals can work their best as the differential heats and cools. If a breather is clogged, the heat will increase pressure in the axle. As the axle cools, a negative pressure could build up behind the seal. These changes in pressure will cause the lips of the seals to deform and leak.

Any leak on an axle should be taken seriously. Ignoring a leak can be very expensive and destroy the bearings, brakes and differential.

After everything is assembled, make sure to use the correct gear lube. Some differentials require a specific friction modifier additive package that might be included in the gear lube, or you might have to add it separately. If the wrong lubricant is used, it might cause noise and damage to the friction plates inside the limited slip mechanism.

Replacing wheel bearings on a vehicle with a live rear axle may not be one of the most frequent jobs you do, but it can be one of the most profitable. While the basics have not changed in more than 60 years, new seal materials and differential designs have added new wrinkles.

Bearings

Replacing rear wheel bearings on a live axle rear suspension requires a few extra steps when compared to a unitized bearing. To remove the axle shaft, the differential must be accessed and the clips that hold the axle in the differential must be removed.

There are three bearing styles — Conrad, roller and ball. Most axles use these types of bearings in a cartridge-type arrangement. They are installed into the axle ends or pressed onto the shaft and possibly held in place with a pressed-on retainer. On some axles, the bore on the housing is tapered and the bearing will fit in only one direction. This is where measuring tools can save you time and maybe multiple part deliveries.

Some axles use a “floating” axle shaft design. This design takes the weight of the vehicle off the axle so all it has to do is transmit power. This allows the hub of the axle to carry a greater load. Some of these axles use tapered roller bearings. Another advantage of a floating axle is if the axle separates from the differential or flange, the wheel will not fall off the axle.

The most critical part of the disassembly is removing the bearing and retainer from the shaft without damaging the axle shaft or housing. Any damage to the surfaces that the seal or bearing ride on can cause a premature failure of the new bearing.

Another rookie mistake made by some technicians is installing the parts in the wrong order. It is not uncommon to press the new bearing onto the axle only to realize the flange plate was not installed.

Look at the differential cover before you quote the job. On snow-belt vehicles, the differential cover is prone to rust. Perforation does happen, but chances are prying on the weakened cover may distort it to the point that it will never seal. Replacement covers are readily available and very economical.

Seals

The main killer of solid axle wheel bearings is a failed seal. Most seals ride on the axle shaft, and they typically have a lip and a spring that holds the lip to the axle. When a seal is installed, take your time installing the axle. Splines can damage the seal and cause leaks.

The area on the axle shaft where the seal and bearings make contact is the most important. It must be free of rust and imperfections. Use only a fine-grade emery paper to clean the axle shaft between the flange and the worn area.

If the surface is grooved or damaged, the axle can be repaired with a sleeve on some applications. If not, the axle should be replaced. Another option for some applications is to install a replacement bearing that repositions the bearing and seal to ride on unworn surfaces.

Make sure the seal is installed in the correct position. A correctly installed bearing may extend out from the housing up to 1/4”. Some axles have small seals that must be positioned properly so pressures can be relieved and the lip can work.

Make sure the breathers on the axle are not clogged. The breather on some axles acts as a PCV valve to keep pressures within a certain range so the seals can work their best as the differential heats and cools. If a breather is clogged, the heat will increase pressure in the axle. As the axle cools, a negative pressure could build up behind the seal. These changes in pressure will cause the lips of the seals to deform and leak.

Any leak on an axle should be taken seriously. Ignoring a leak can be very expensive and destroy the bearings, brakes and differential.

After everything is assembled, make sure to use the correct gear lube. Some differentials require a specific friction modifier additive package that might be included in the gear lube, or you might have to add it separately. If the wrong lubricant is used, it might cause noise and damage to the friction plates inside the limited slip mechanism.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Moticont Adds Servo Actuator to SDLM Series

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.